Tellurium-zinc sulfide heterojunction compound hollow microsphere and preparation method thereof

A technology of hollow microspheres and heterojunctions, applied in the field of environmental governance, can solve the problems of long removal time, high cost, only 1-2 kinds of removal at a time, and low removal efficiency of low-concentration heavy metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

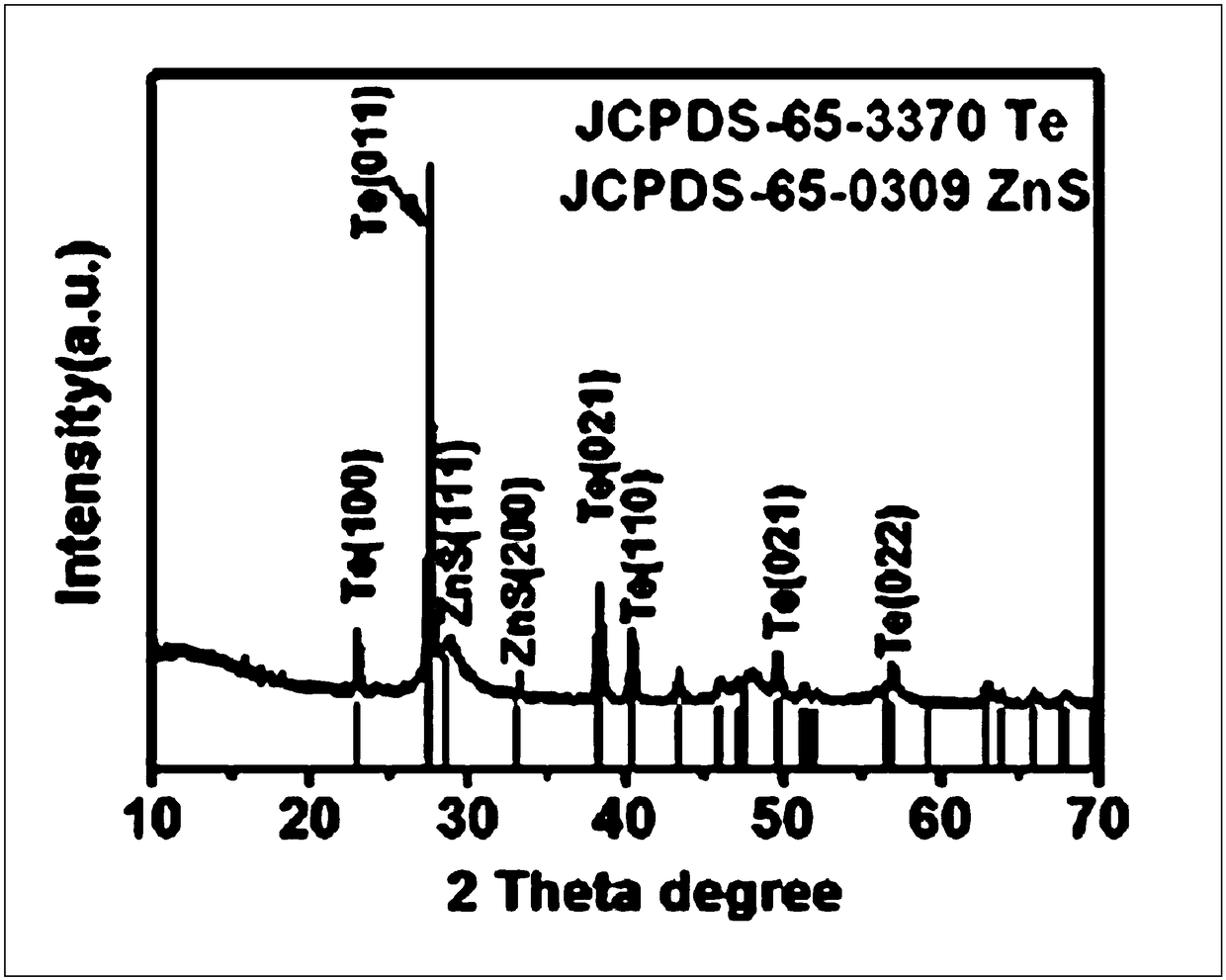

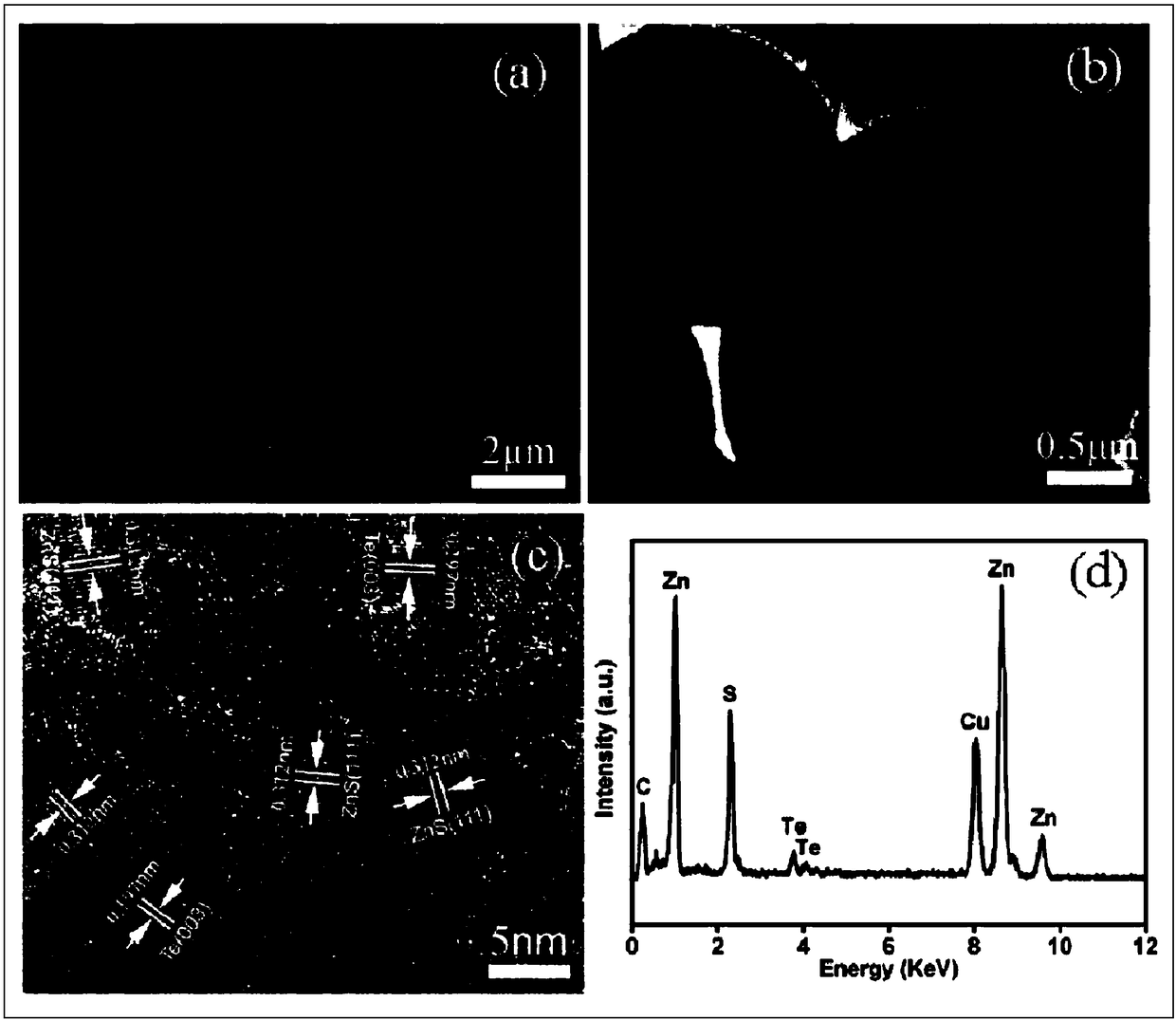

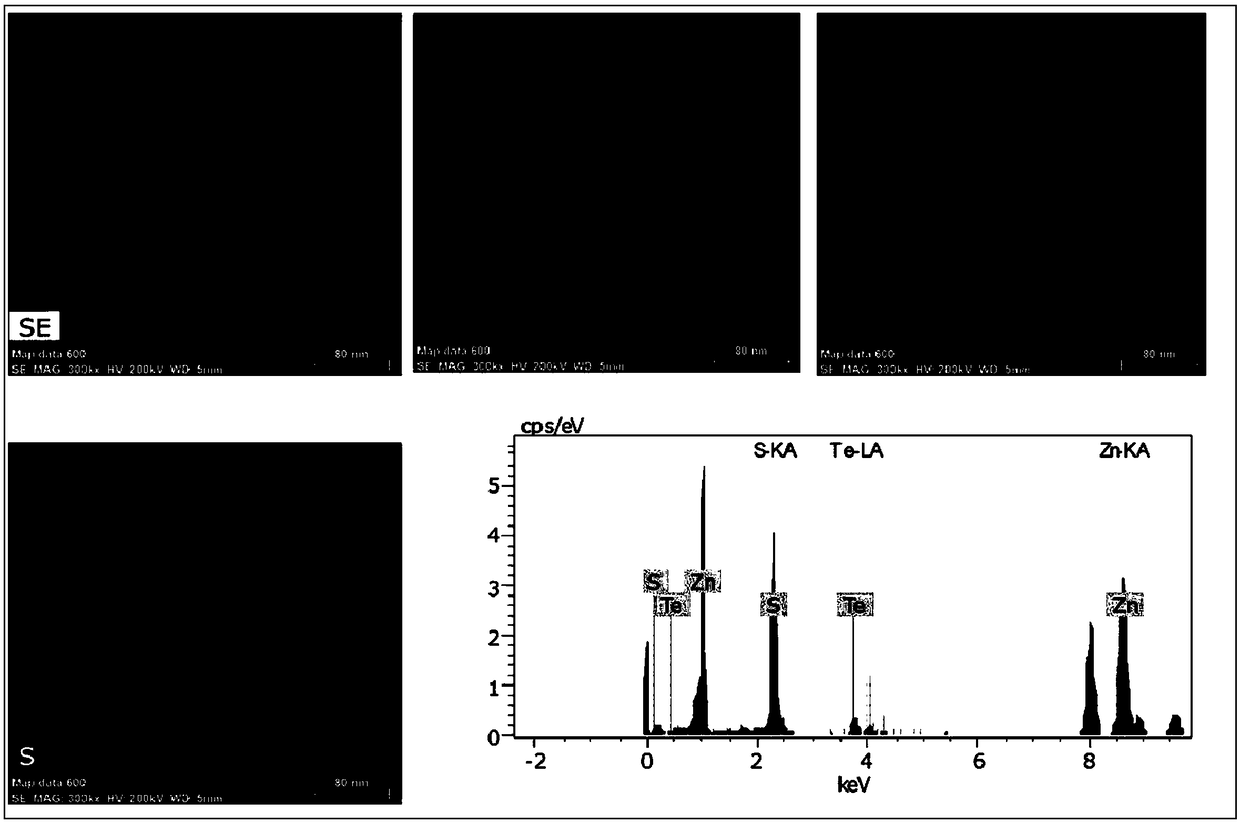

[0034] Example 1: Weigh 0.2 g of tellurium diethyldithiocarbamate, 0.2 g of zinc N-ethyl-N-phenyldithiocarbamate, 0.2 g of 2,2'-dithiodibenzoic acid, Measure 27.6ml of chloroform solvent and 5ml of 20% ammonia; diethyldithiocarbamate tellurium, N-ethyl-N-phenyldithiocarbamate, 2,2'-dithiodithiocarbamate Benzoic acid was dissolved in chloroform, stirred for 10-15 minutes, then added ammonia water, and stirred for 3-5 minutes to form a mixed solution; the mixed solution was placed in a polytetrafluoroethylene reactor, and at 130 ° C, 4 reactions were carried out. hours; take out the inner liner of the reactor, pour the reactant into the centrifuge tube, remove the liquid, and leave the solid in the centrifuge tube; add alcohol to wash the solid, ultrasonicate for 5 minutes, and centrifuge at 10000 r / min for 10 minutes to remove the liquid and solid. The layer was washed in the same way as water-water-alcohol in sequence; the product was placed under the condition of 90°C and dri...

Embodiment 2

[0035] Example 2: Weigh 0.3 g of sodium tellurite, 0.3 g of zinc N-ethyl-N-phenyl dithiocarbamate, 0.35 g of 2,2'-dithiodibenzoic acid, and weigh 40.5 ml of solvent Chloroform and 10.7 ml of 20% ammonia. Dissolve sodium tellurite, zinc N-ethyl-N-phenyldithiocarbamate, and 2,2'-dithiodibenzoic acid in chloroform, stir for 10-15 minutes, add ammonia water, and stir for 3 -5 minutes to form a mixed solution; put the mixed solution in a polytetrafluoroethylene reactor, and react at 130 ° C for 4 hours; take out the inner tank of the reactor, pour the reactant into a centrifuge tube, and remove it by suction The liquid and the solid were left in the centrifuge tube; the solid was washed with alcohol, and after sonicating for 6 minutes, centrifuged at 10,000 r / min for 10 minutes to remove the liquid, and the solid layer was washed in the order of water-water-alcohol in the same way; the product was placed in 90 Under the condition of ℃, drying was carried out for 5 h to obtain ZnS / ...

Embodiment 3

[0036]Example 3: Weigh 0.1 g of tellurium diethyldithiocarbamate, 0.2 g of zinc N-ethyl-N-phenyldithiocarbamate, 0.1 g of thiourea, and weigh out 13.5 ml of chloroform and 3.7 ml of solvent 20% ammonia water. Dissolve diethyldithiocarbamate tellurium, N-ethyl-N-phenyldithiocarbamate, and thiourea in chloroform, stir for 10-15 minutes, add ammonia water, and stir for 3-5 minutes to form Mixed solution; put the mixed solution in a polytetrafluoroethylene reaction kettle, and react at 130 ° C for 4 hours; take out the inner liner of the reaction kettle, pour the reactant into a centrifuge tube, absorb the liquid, and leave the solid. In a centrifuge tube; the solid was washed with alcohol, and after ultrasonication for 8 minutes, centrifuged at 10,000 r / min for 10 minutes to remove the liquid, and the solid layer was washed with water-water-alcohol in the same way; the product was placed at 90 ℃. , and dried for 5h to obtain ZnS / Te microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com