A kind of preparation method of copper clad laminate

A technology for copper clad laminates and preparation steps, which is applied in the field of preparation of copper clad laminates, can solve problems such as poor mechanical properties and insulation properties, and achieve the effects of improving mechanical properties and thermal conductivity, toughness, and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

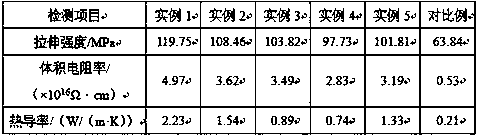

Examples

example 1

[0025]Mix the glass fiber and silane coupling agent in a beaker at a mass ratio of 1:5, and add water 10 times the mass of the glass fiber into the beaker, and move the beaker into a magnetic stirrer with a digital display speed measurement and constant temperature. Under the condition of 280r / min, stir and mix at a constant temperature for 3 hours, filter to obtain a filter cake, dry the filter cake at a temperature of 90°C for 40 minutes, and obtain pretreated glass fiber, and mix the pretreated glass fiber with rubber emulsion Mix at a mass ratio of 1:8, soak at a constant temperature of 55°C for 2 hours, and then filter to obtain modified glass fibers; mix the modified glass fibers and polypropylene fibers at a mass ratio of 1:3, and pour them into the modified glass Add silicon carbide fiber of 0.6 times the mass of modified glass fiber to the mixture of fiber and polypropylene fiber, stir and mix for 40min at a speed of 200r / min to obtain a mixed fiber material, which is ...

example 2

[0027] Mix glass fiber and polypropylene fiber at a mass ratio of 1:3, and add silicon carbide fiber 0.6 times the mass of glass fiber to the mixture of glass fiber and polypropylene fiber, stir and mix for 40 minutes at a speed of 200r / min to obtain a mixture Fiber material, the mixed fiber material is opened, carded, laid and needle-punched to obtain a semi-finished glass fiber board. Graphite oxide and paraffin wax are mixed in the ball mill according to the mass ratio of 1:3, and zirconia ball milling beads with 5 times the mass of graphite oxide are added to the ball mill, and after ball milling and mixing for 40 minutes, the material is discharged to obtain pretreated graphite; Mix sepiolite and water in a flask at a mass ratio of 1:8, add silicon nitride powder 0.5 times the mass of sepiolite and aluminum nitride powder 0.4 times the mass of sepiolite to the flask, and move the flask into an ultrasonic vibration instrument, ultrasonically oscillate for 25 minutes at a f...

example 3

[0029] Mix the glass fiber and silane coupling agent in a beaker at a mass ratio of 1:5, and add water 10 times the mass of the glass fiber into the beaker, and move the beaker into a magnetic stirrer with a digital display speed measurement and constant temperature. Under the condition of 280r / min, stir and mix at a constant temperature for 3 hours, filter to obtain a filter cake, dry the filter cake at a temperature of 90°C for 40 minutes, and obtain pretreated glass fiber, and mix the pretreated glass fiber with rubber emulsion Mix at a mass ratio of 1:8, soak at a constant temperature of 55°C for 2 hours, and then filter to obtain modified glass fibers; mix the modified glass fibers and polypropylene fibers at a mass ratio of 1:3, and rotate at a speed of 200r / Stir and mix for 40 minutes under the condition of 1 min to obtain a mixed fiber material. After the mixed fiber material is opened, carded, laid and needled, a semi-finished glass fiber board is obtained. Finally, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com