Middle-boron-content rich fuel propellant with high burning rate pressure exponent

A fuel-rich propellant, boron content technology, applied in offensive equipment, compressed gas generation, explosives, etc., can solve the problems of boron-rich fuel-rich propellant energy performance, burning rate and pressure index difficulties, etc., to improve the gas phase product Concentration, increased gas production, increased heat absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Propellant composition

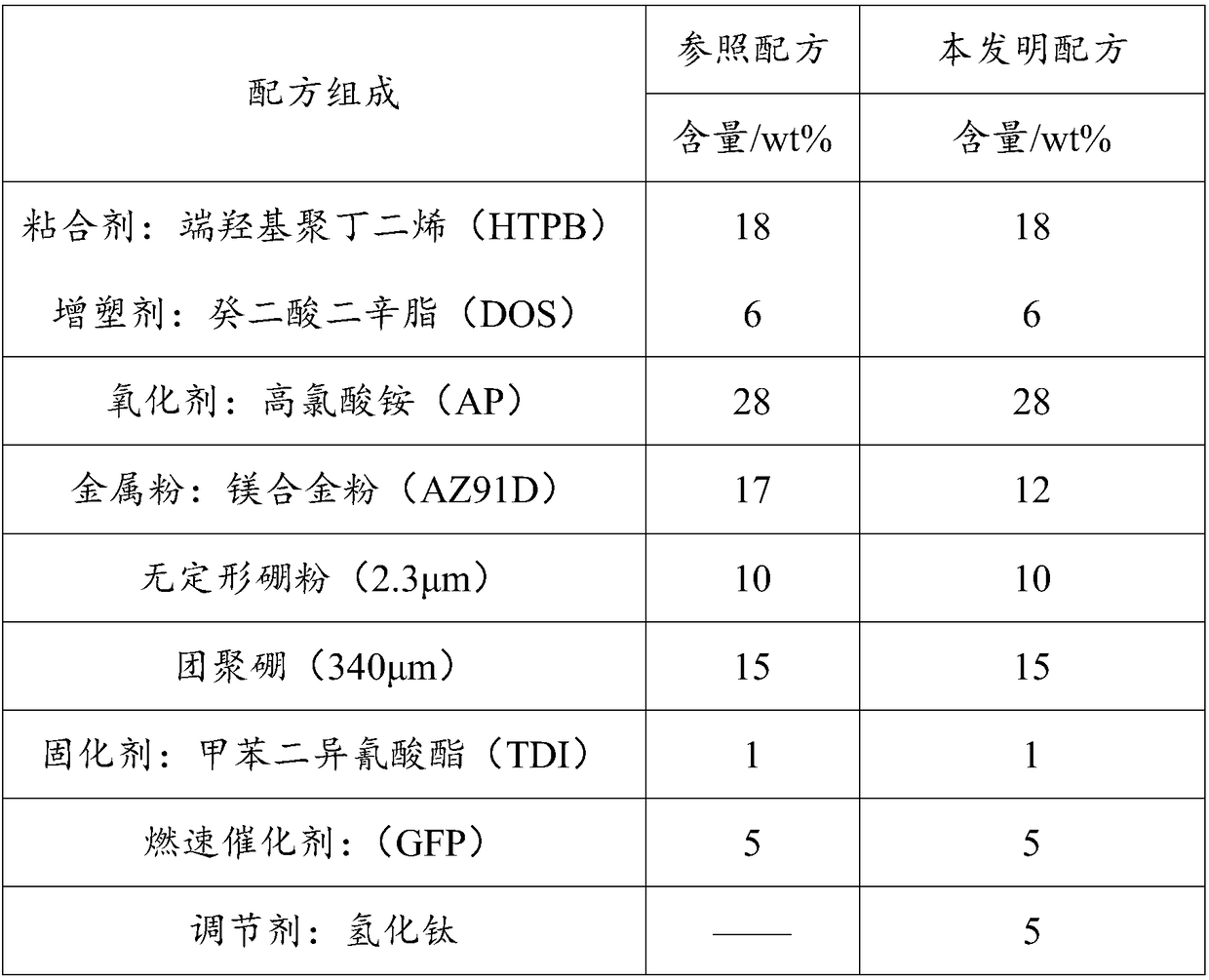

[0030] The formula compositions of the reference formula and the propellant of the present invention are shown in Table 1 below, and the contents thereof are expressed in mass percent.

[0031] Formulation of the present invention in the embodiment 1 of table 1 and reference formulation

[0032]

[0033](2) Performance of boron-rich fuel-rich propellant: the burning rate pressure index of the propellant with reference to the formula is 0.35 at 0.5-2.0MPa, and the measured calorific value of the oxygen bomb is -23185.9kJ / kg; the propellant of the formula of the present invention is at 0.5 The burning rate pressure index at -2.0MPa is 0.44, and the measured calorific value of the oxygen bomb is -23791.4kJ / kg.

Embodiment 2

[0035] (1) Propellant composition

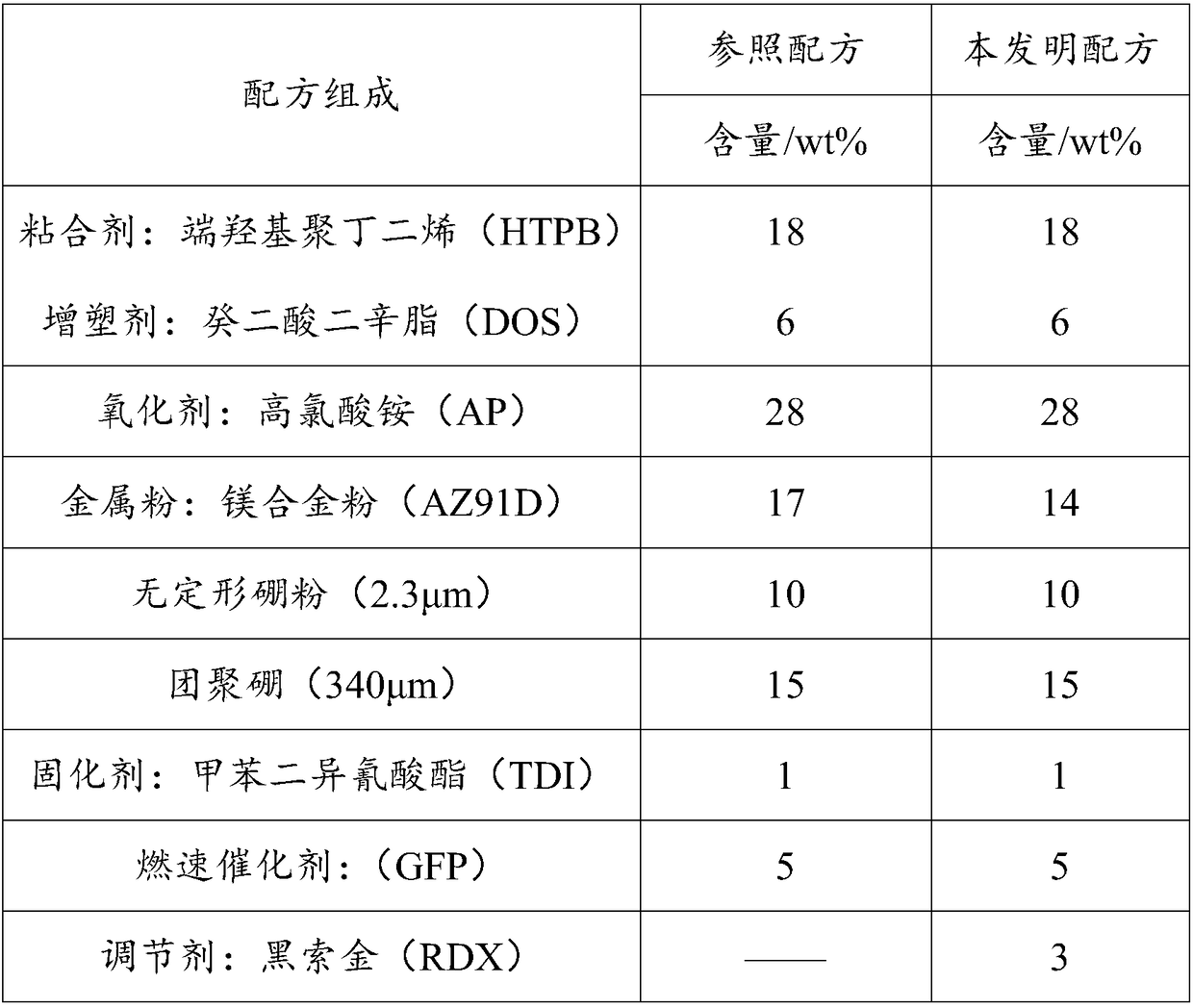

[0036] The formula compositions of the reference formula and the propellant of the present invention are shown in Table 2 below, and the contents thereof are expressed in mass percent.

[0037] The formula of the present invention in the embodiment 2 of table 2 and reference formula form

[0038]

[0039] (2) Performance of boron-rich fuel-rich propellant: the burning rate pressure index of the propellant with reference to the formula is 0.35 at 0.5-2.0MPa, and the measured calorific value of the oxygen bomb is -23185.9kJ / kg; the propellant of the formula of the present invention is at 0.5 The burning rate pressure index at -2.0MPa is 0.44, and the measured calorific value of the oxygen bomb is -24086.5kJ / kg.

Embodiment 3

[0041] (1) Propellant composition

[0042] The formula compositions of the reference formula and the propellant of the present invention are shown in Table 3 below, and the contents thereof are expressed in mass percent.

[0043] The formula of the present invention in the embodiment 3 of table 3 and reference formula form

[0044]

[0045] (2) Performance of boron-rich fuel-rich propellant: the burning rate pressure index of the propellant with reference to the formula is 0.35 at 0.5-2.0MPa, and the measured calorific value of the oxygen bomb is -23185.9kJ / kg; the propellant of the formula of the present invention is at 0.5 The burning rate pressure index at -2.0MPa is 0.42, and the measured calorific value of the oxygen bomb is -24043.6kJ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com