A kind of environment-friendly interior wall putty powder and preparation method thereof

An interior wall putty powder, an environmentally friendly technology, applied in antifouling/underwater coatings, filling pastes, paints containing biocides, etc., can solve problems such as insufficient whiteness and texture, poor washability, and coating cracks , to achieve excellent comprehensive performance, strong water resistance and cohesiveness, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

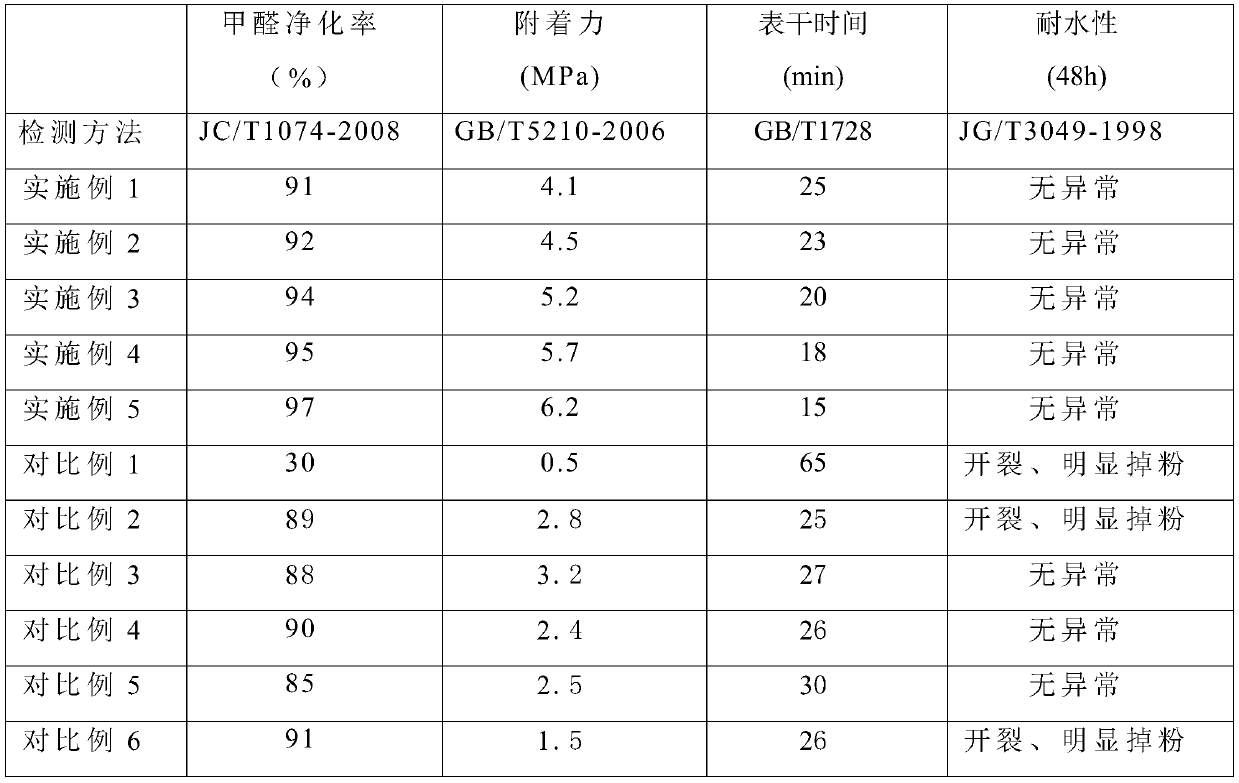

Examples

Embodiment 1

[0022] An environment-friendly interior wall putty powder, comprising the following components by weight: 25 parts of clay powder, 15 parts of white Portland cement, 1 part of pine oil, 1 part of fragrant tree oil, 0.5 parts of hydroxypropyl Beta-cyclodextrin 1 part, 1 part of cationic guar gum silicate, 1.5 parts of cationic guar gum polyether phosphate, 2 parts of negative ion powder.

[0023] The preparation method of the cationic guar silicate comprises the following steps: adding 30 g of cationic guar gum and 30 g of sodium silicate to 150 g of water, stirring and reacting at 50° C. for 10 hours, and then adding 20% ethanol solution Settled out, centrifuged, and baked in a vacuum oven at 90°C for 10 hours.

[0024] The preparation method of the cationic guar polyether phosphate salt comprises the following steps: adding 30 g of cationic guar gum and sodium nonylphenol polyether-6 phosphate (CAS: 12068-19-8) to 150 g of water , stirred and reacted at 50°C for 10 hours, ...

Embodiment 2

[0027] An environment-friendly interior wall putty powder, comprising the following components by weight: 28 parts of clay powder, 18 parts of white Portland cement, 2 parts of pine oil, 1 part of fragrant tree oil, 1.5 parts of hydroxypropyl Beta-cyclodextrin 1.5 parts of cationic guar silicate, 2 parts of cationic guar polyether phosphate, and 3 parts of negative ion powder.

[0028] The preparation method of the cationic guar silicate comprises the following steps: adding 40 g of cationic guar gum and 30 g of sodium silicate to 165 g of water, stirring and reacting for 13 hours at 53° C. Settled out, centrifuged, and baked in a vacuum oven at 93°C for 11 hours.

[0029] The preparation method of the cationic guar polyether phosphate salt comprises the following steps: adding 35 g of cationic guar gum and 30 g of nonylphenol polyether-6 phosphate sodium (CAS: 12068-19-8) to 170 g of water , stirred and reacted at 54°C for 13 hours, then precipitated in 20% ethanol solution,...

Embodiment 3

[0032] An environment-friendly interior wall putty powder, comprising the following components by weight: 30 parts of clay powder, 20 parts of white Portland cement, 2 parts of pine oil, 2 parts of fragrant tree oil, 2 parts of hydroxypropyl Beta-cyclodextrin 2 parts, 2 parts of cationic guar gum silicate, 2 parts of cationic guar gum polyether phosphate, 3.5 parts of negative ion powder.

[0033] The preparation method of the cationic guar silicate comprises the following steps: adding 50 g of cationic guar gum and 30 g of sodium silicate to 180 g of water, stirring and reacting for 14 hours at 57° C. Settled out, centrifuged, and baked in a vacuum oven at 97°C for 11 hours.

[0034] The preparation method of the cationic guar polyether phosphate salt comprises the steps of: adding 40 g of cationic guar gum and 30 g of nonylphenol polyether-6 phosphate sodium (CAS: 12068-19-8) to 175 g of water , stirred and reacted at 56°C for 14 hours, then precipitated in 20% ethanol solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com