Preparation method of milk product with function of lowering blood pressure

A technology for lowering blood pressure and dairy products, which is applied in the field of food processing to achieve the effects of high purity, improved fermentation efficiency, and increased activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

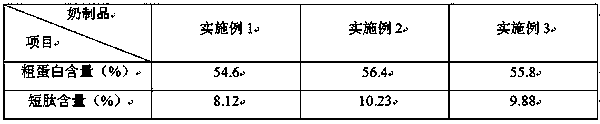

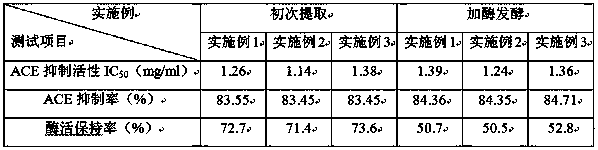

Examples

Embodiment 1

[0046] A. Fresh shellfish is steamed, chopped, and placed in a -20°C refrigerator for freezing. After 6 hours, it is transferred to a vacuum freeze dryer, freeze-dried for 48 hours, and crushed through a 40-mesh sieve to obtain dried shellfish powder;

[0047] B. Get the dried green tea leaves and grind them into fine powder, then spray 20% of the tea leaves with a mass fraction of 6% tannase solution, mix and leave to react for 40 minutes to obtain green tea enzymatic solution;

[0048] C. Add the dried shellfish powder into distilled water for homogenization according to the material-to-liquid ratio of 1:3, adjust the pH to 6.3, add 20 parts of green tea enzymatic solution, 60 parts of raw goat milk, mix well, and then add 40 mg / ml of magnetic carbon microspheres, after autoclaving for 20 minutes, the culture medium was obtained;

[0049] The preparation method of described magnetic carbon microsphere is as follows:

[0050] (1) Dissolve waste bean dregs and potassium carb...

Embodiment 2

[0065] A. Fresh shellfish is steamed, chopped, and placed in a -20°C refrigerator for freezing. After 6 hours, it is transferred to a vacuum freeze dryer, freeze-dried for 48 hours, and crushed through a 40-mesh sieve to obtain dried shellfish powder;

[0066] B. Get the dried green tea leaves and grind them into fine powder, then spray 30% of the tea leaves with a mass fraction of 8% tannase solution, mix and leave to react for 60 minutes to obtain green tea enzymatic solution;

[0067] C. Add the dried shellfish powder into distilled water for homogenization according to the material-to-liquid ratio of 1:4, adjust the pH to 7.0, add 40 parts of green tea enzymolysis solution, 80 parts of raw milk, mix well, and then add 60 mg / ml of magnetic carbon microspheres, after autoclaving for 20-30 minutes, the culture medium was obtained;

[0068] The preparation method of described magnetic carbon microsphere is as follows:

[0069] (1) Dissolve waste bean dregs and potassium carb...

Embodiment 3

[0084] A. Fresh shellfish is steamed, chopped, and placed in a -20°C refrigerator for freezing. After 6 hours, it is transferred to a vacuum freeze dryer, freeze-dried for 48 hours, and crushed through a 40-mesh sieve to obtain dried shellfish powder;

[0085] D. get the dried green tea leaves and grind them into fine powder, then spray 25% of the tea leaves with a mass fraction of 7% tannase solution, mix and leave to react for 50 minutes to obtain green tea enzymatic solution;

[0086] C. Add the dried shellfish powder into distilled water for homogenization according to the material-to-liquid ratio of 1:4, adjust the pH to 6.5, add 45 parts of green tea enzymatic solution, 70 parts of raw goat milk, mix well, and then add 50 mg / ml of magnetic carbon microspheres, after autoclaving for 30 minutes, the culture medium was obtained;

[0087] The preparation method of described magnetic carbon microsphere is as follows:

[0088] (1) Dissolve waste bean dregs and potassium carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com