Process for nitrosation-anaerobic ammonia oxidation immobilization and aquaculture waste water treatment

A technology for anammox and aquaculture wastewater is applied in the field of nitrosation-anammox immobilization and aquaculture wastewater treatment technology, which can solve the problems of large demand for organic carbon sources, increased operating costs, and large floor space. Achieve good TN and COD removal, lower processing costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

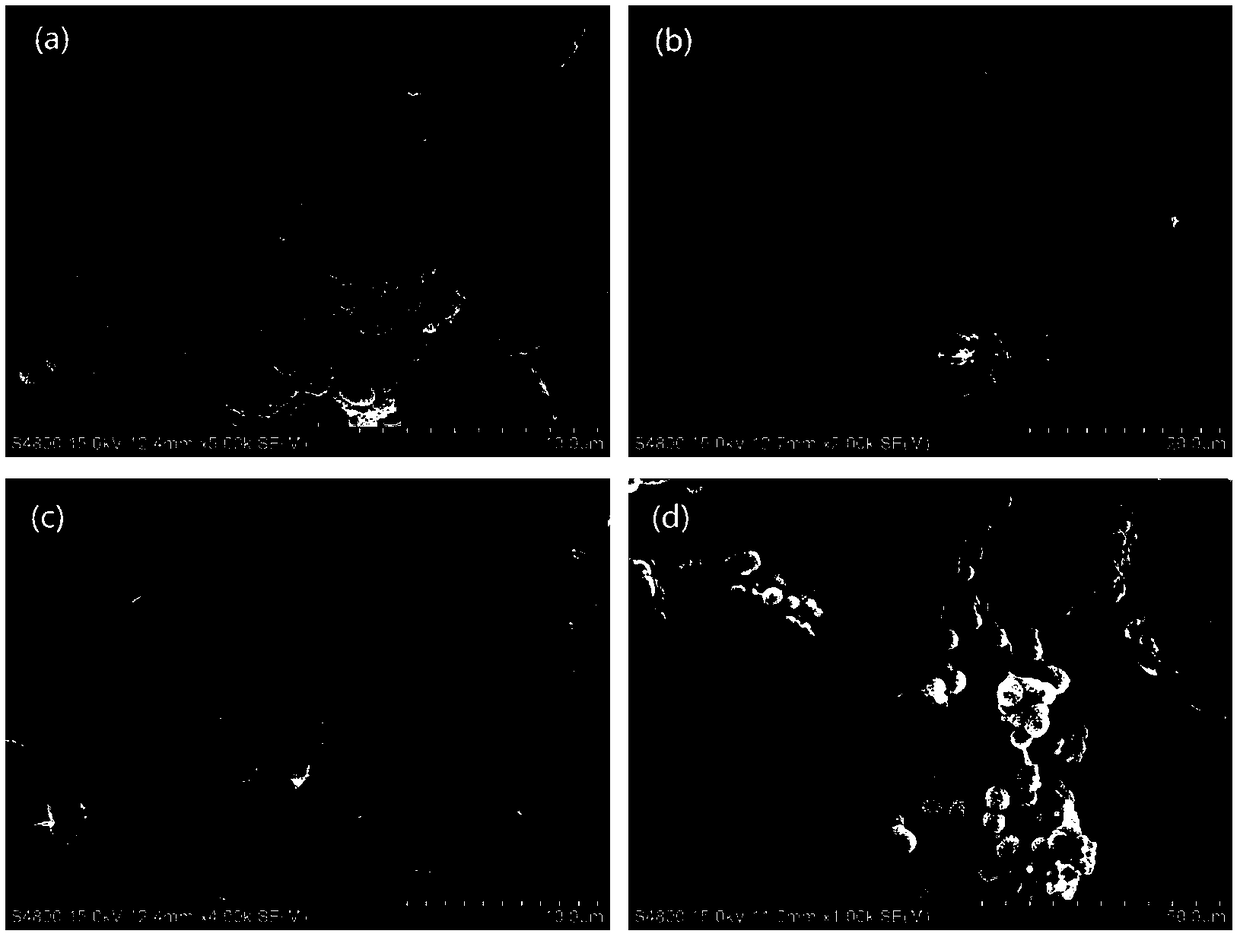

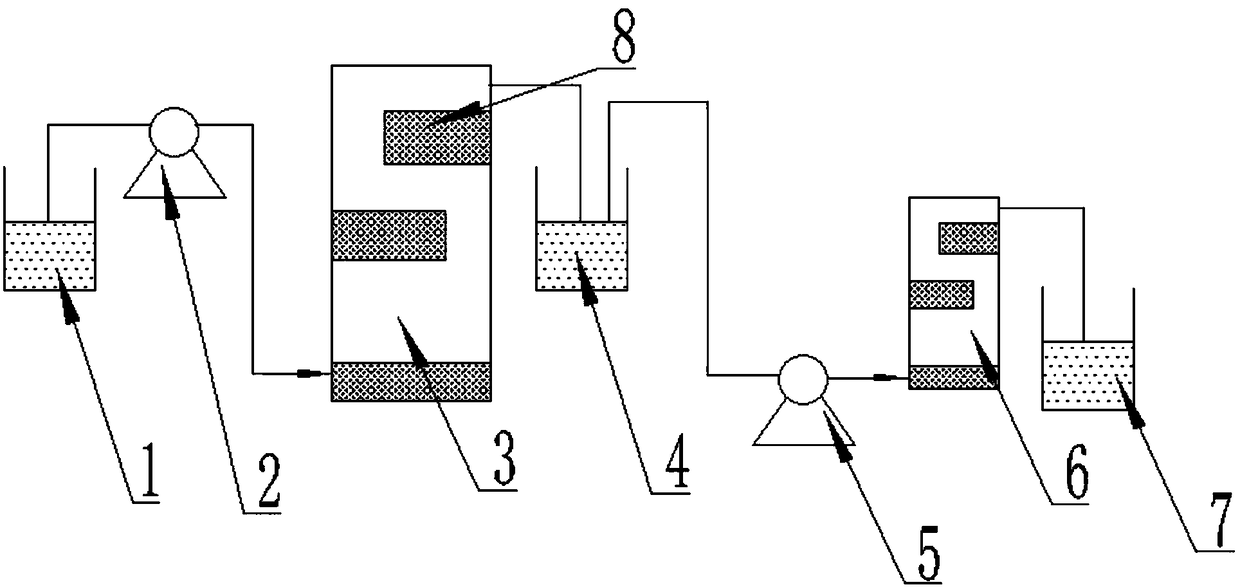

[0045] Such as Figure 1-2 As shown, the aquaculture wastewater nitrosation-ANAMMOX treatment process provided in this embodiment includes a nitrosation stage and anammox stage, and the nitrosation stage is carried out in the aeration tank 3, using immobilized microbial pellets Treatment, the hydraulic retention time is 12h, the dissolved oxygen is 2mg / L, and the pH of the influent water is controlled at 8; the anaerobic ammonium oxidation stage is carried out in the anaerobic tank 6, and the immobilized microbial pellets are used for treatment, and the temperature is controlled at 32 °C. The residence time is 4h, the dissolved oxygen is less than 0.2mg / L, and the pH of the influent is controlled at 8. Both the sludge concentration of the aeration tank 3 and the anaerobic tank 6 are 3.3g / L.

[0046] The preparation method of immobilized microbial pellet in the present embodiment is as follows:

[0047] Wash and remove impurities from the bottom mud of the breeding pond, plac...

Embodiment 2

[0052] This example is basically the same as Example 1, except that the components of the immobilized microbial pellet 8 in Example 2 are calculated by mass percent concentration: 2% sodium alginate, 3% boric acid solution, polyvinyl alcohol The concentration is 7%, the artificial zeolite is 1%, the experimental sludge is 40%, and the rest is water.

Embodiment 3

[0054] This example is basically the same as Example 1, except that the components of the immobilized microbial pellet 8 in Example 3 are calculated by mass percent concentration: sodium alginate 1.5%, boric acid solution 4%, polyvinyl alcohol The concentration is 6%, the artificial zeolite is 2%, the experimental sludge is 35%, and the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com