High polymer grouting material and preparation method thereof

A technology of grouting material and high polymer, which is applied in the field of high polymer grouting material and its preparation, which can solve the problem of compression and tensile properties of consolidated body inferior to epoxy grout, difficulty in finding active diluent, and easy foaming and other problems, to achieve the effect of suitable curing time, guaranteed operation time and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A polymer grouting material, the polymer grouting material is composed of component A and component B in a ratio of 1.8:1:

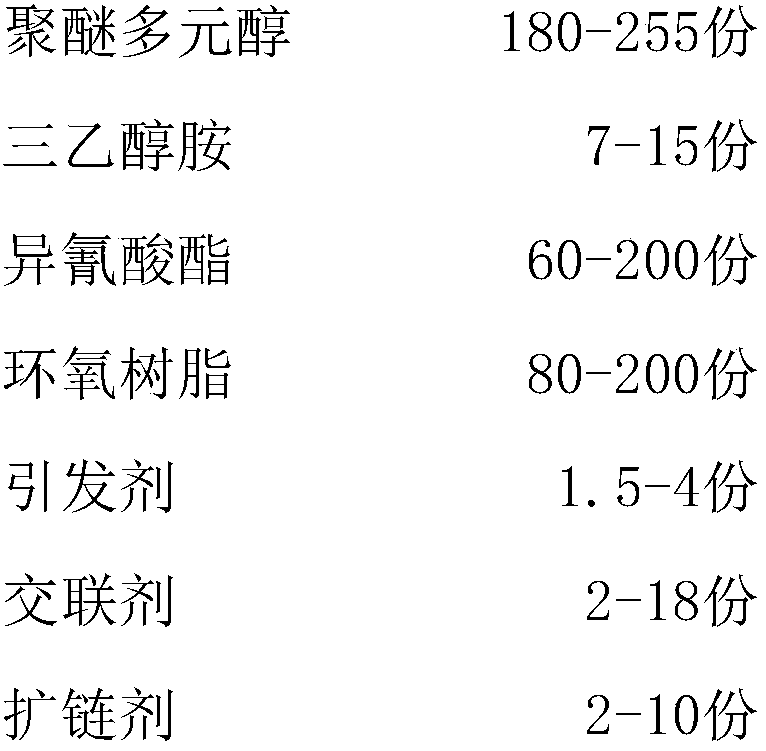

[0047] The raw materials of the component A include according to parts by weight:

[0048]

[0049] The raw material of institute component B comprises according to weight part:

[0050]

[0051] The hydroxyl value of the polyether polyol is 340-380mgKOH / g, and the molecular weight is 400-1000; the epoxy resin is a bisphenol A type epoxy resin; the isocyanate is diphenylmethane diisocyanate; the trigger The agent is azobisisobutyronitrile; the crosslinking agent is a mixture of dicumyl peroxide and polyvinylpyrrolidone, and its mass ratio is 1:2; the chain extender is ethylene glycol; the plasticizer The agent is epoxy soybean oil; the defoamer is polyether modified polydimethylsiloxane; the catalyst is bis(dimethylaminoethyl) ether, triethylenediamine and polymethylaminomethyl Phenol is compounded according to the weight ratio of 1.5:0.5:...

Embodiment 2

[0057] A polymer grouting material, the polymer grouting material is composed of component A and component B in a ratio of 1.9:1:

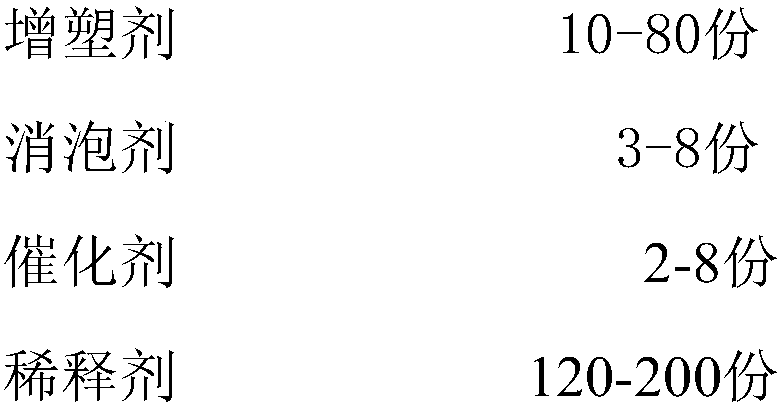

[0058] The raw materials of the component A include according to parts by weight:

[0059]

[0060] The raw material of institute component B comprises according to weight part:

[0061]

[0062] The polyether polyol is a combined polyether polyol, synthesized from ethylene oxide and propylene oxide, the mass ratio of the two polyether polyols is 1:1, and the hydroxyl value of the polyether polyol is 400-420mgKOH / g, molecular weight 800-1500; the epoxy resin is bisphenol A type epoxy resin and bisphenol F type epoxy resin compounded according to the mass ratio of 1:1; the isocyanate is di Phenylmethane diisocyanate, p-phenylene diisocyanate and xylylene diisocyanate are compounded according to the weight ratio of 1:0.8:1; the initiator is benzoyl peroxide and dicumyl peroxide according to the mass The ratio is 1:1; the crosslinking agent i...

Embodiment 3

[0068] A polymer grouting material, the polymer grouting material is composed of component A and component B in a ratio of 2.0:1:

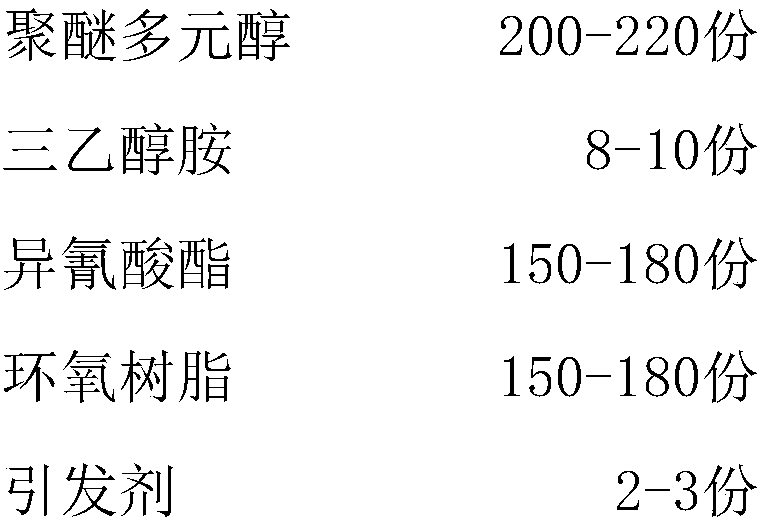

[0069] The raw materials of the component A include according to parts by weight:

[0070]

[0071]

[0072] The raw material of institute component B comprises according to weight part:

[0073]

[0074] The polyether polyol is a combined polyether polyol, the hydroxyl value of the polyether polyol is 390-430mgKOH / g, and the molecular weight is 1000-1500; the epoxy resin is a bisphenol F epoxy resin; The isocyanate is compounded from diphenylmethane diisocyanate, p-phenylene diisocyanate and xylylene diisocyanate in a weight ratio of 1.5:1:1; the initiator is azobisisobutyronitrile and benzene peroxide Formyl is compounded according to the mass ratio of 1:2; the crosslinking agent is a mixture of dicumyl peroxide and polyvinylpyrrolidone, and its mass ratio is 1:2.2; the chain extender is 1,4 -Butanediol; the plasticizer is formed by c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com