A kind of aluminum oxide polishing solution for sapphire polishing and preparation method thereof

A polishing liquid and alumina technology, applied in the field of sapphire polishing, can solve the problems of excessive loss of auxiliary materials, high wafer surface roughness, low polishing efficiency and yield, etc., achieving low cost, excellent lubricating effect, and being conducive to industrialization. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

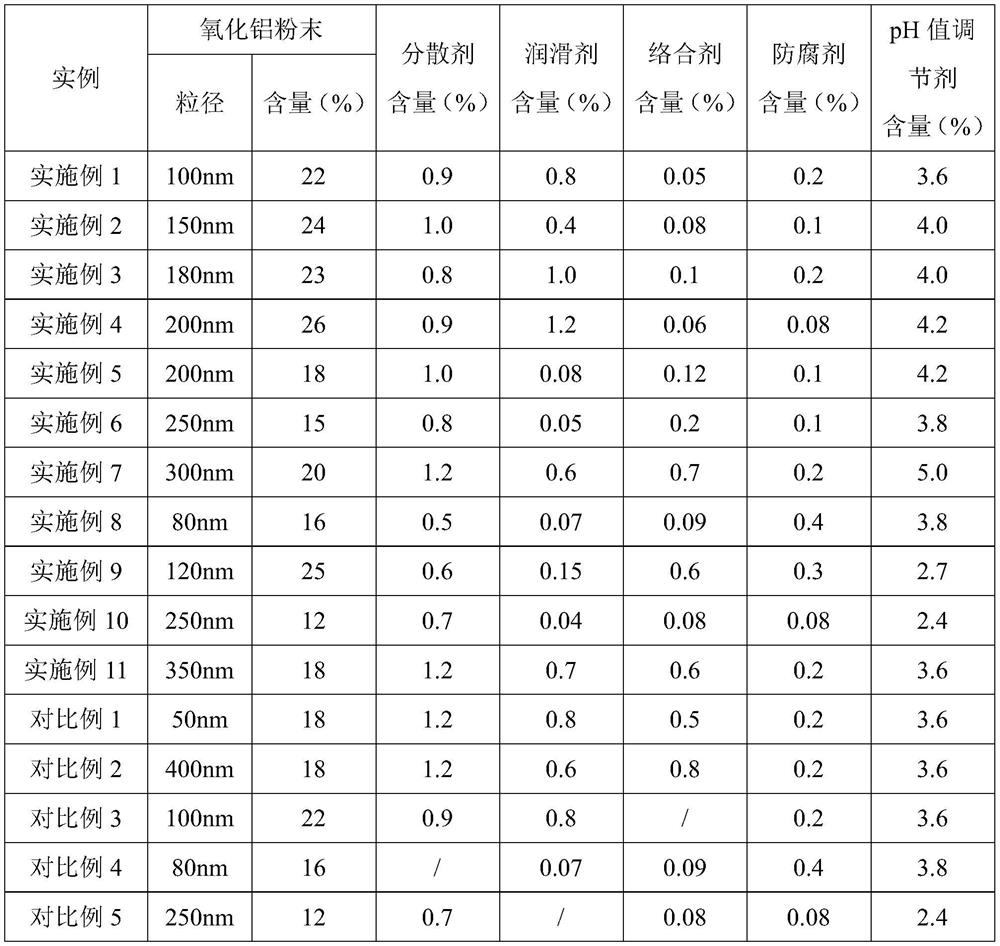

Examples

Embodiment 1

[0030] The dispersant used in embodiment 1 is polyvinyl alcohol, the lubricant is polyethylene glycol 200 and polyethylene glycol 400, the complexing agent is sodium gluconate, the preservative is benzotriazole, and the pH regulator is Diethanolamine and Tetramethylammonium Hydroxide.

Embodiment 2

[0031]The dispersant used in embodiment 2 is alkylphenol polyoxyethylene ether, the lubricant is polyethylene glycol 200, the complexing agent is sodium lactate, the preservative is benzotriazole, and the pH regulator is triethanolamine, tetra Methylammonium Hydroxide and Tetraethylammonium Hydroxide.

Embodiment 3

[0032] The dispersant used in embodiment 3 is fatty alcohol polyoxyethylene ether, and lubricant is polyethylene glycol 200 and glycerin, and complexing agent is potassium citrate, and antiseptic is benzotriazole, and pH regulator is four Ethyl ammonium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com