Ce-Mn/SAPO-34 molecular sieve catalyst and preparation method thereof

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc. It can solve the problems of catalyst dust resistance, high anti-poisoning performance, increased energy consumption, etc., and achieve good low temperature Activity and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

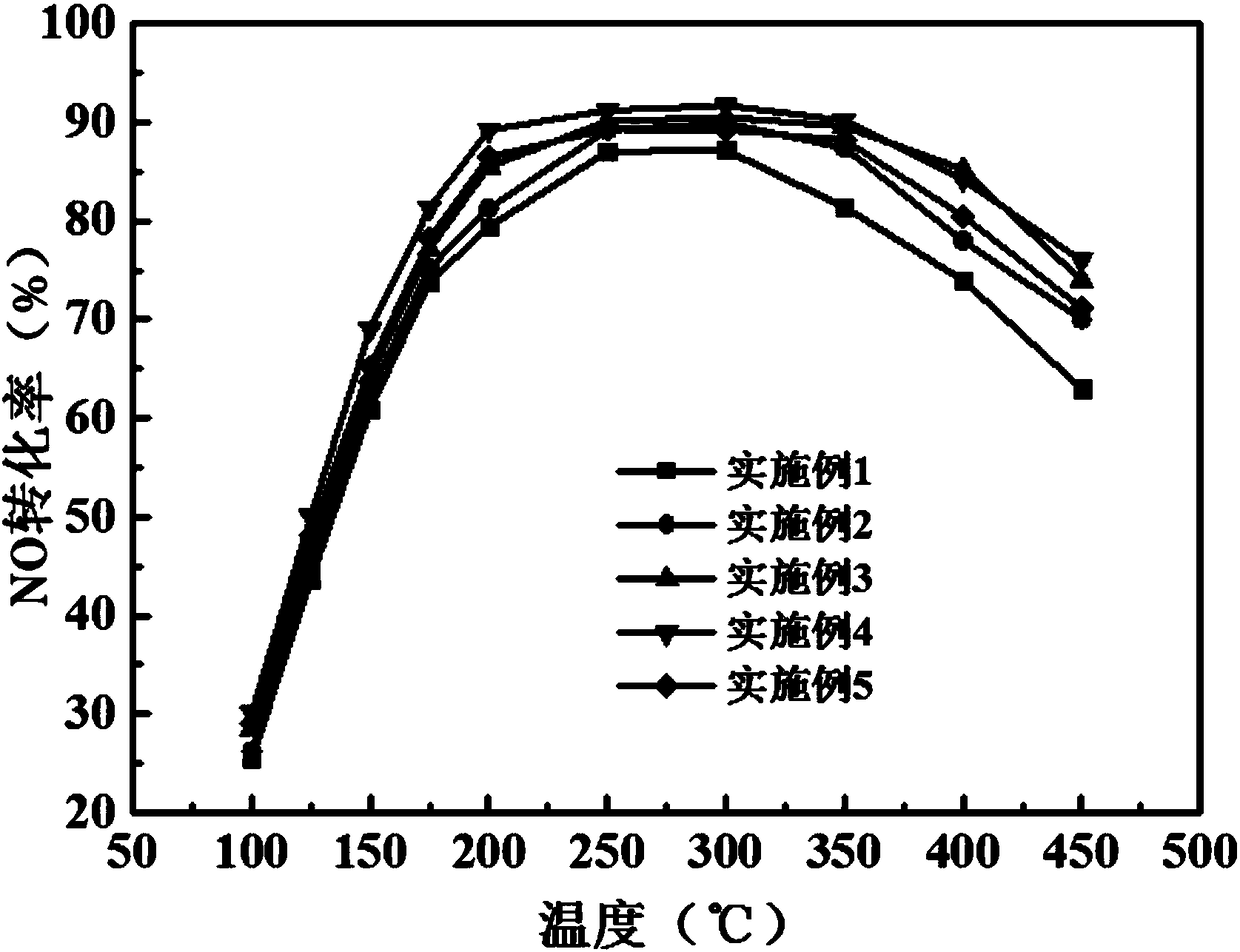

Examples

Embodiment 1

[0030] A preparation method of Ce-Mn / SAPO-34 molecular sieve catalyst, is characterized in that, comprises the following steps:

[0031] 1) Mix phosphoric acid with deionized water, then add pseudo-boehmite, stir for 2 hours, mix well, add ethyl orthosilicate, stir well, then add organic amine template agent morpholine dropwise to obtain mixture A;

[0032] P in the mixture A 2 o 5 、H 2 O, Al 2 o 3 , SiO 2 The molar ratio of morpholine is 1.0:60:1.0:0.6:2.5;

[0033] 2) Stir the mixture A obtained in step 1) fully to obtain a gel-like mixture A; put the gel-like mixture A into a hydrothermal reaction kettle, crystallize at 200°C for 48h, cool at room temperature, and dissolve the solid The crystallized product is separated from the mother liquor, washed until neutral, dried, and calcined at 500-600°C in air for 6 hours to obtain the catalyst carrier SAPO-34 molecular sieve;

[0034] 3) adding manganese acetylacetonate O and cerium nitrate into acetone, fully stirring un...

Embodiment 2

[0044] A preparation method of Ce-Mn / SAPO-34 molecular sieve catalyst, is characterized in that, comprises the following steps:

[0045] 1) Mix phosphoric acid with deionized water, then add pseudo-boehmite, stir for 2 hours, mix well, add ethyl orthosilicate, stir well, then add organic amine template agent morpholine dropwise to obtain mixture A;

[0046] P in the mixture A 2 o 5 、H 2 O, Al 2 o 3 , SiO 2 The molar ratio of morpholine is 1.0:60:1.0:0.6:2.5;

[0047]2) Stir the mixture A obtained in step 1) fully to obtain a gel-like mixture A; put the gel-like mixture A into a hydrothermal reaction kettle, crystallize at 200°C for 48h, cool at room temperature, and dissolve the solid The crystallized product is separated from the mother liquor, washed until neutral, dried, and calcined at 500-600°C in air for 6 hours to obtain the catalyst carrier SAPO-34 molecular sieve;

[0048] 3) adding manganese acetylacetonate O and cerium nitrate into acetone, fully stirring unt...

Embodiment 3

[0058] A preparation method of Ce-Mn / SAPO-34 molecular sieve catalyst, is characterized in that, comprises the following steps:

[0059] 1) Mix phosphoric acid with deionized water, then add pseudo-boehmite, stir for 2 hours, mix well, add ethyl orthosilicate, stir well, then add organic amine template agent morpholine dropwise to obtain mixture A;

[0060] P in the mixture A 2 o 5 、H 2 O, Al 2 o 3 , SiO 2 The molar ratio of morpholine is 1.0:60:1.0:0.6:2.5;

[0061] 2) Stir the mixture A obtained in step 1) fully to obtain a gel-like mixture A; put the gel-like mixture A into a hydrothermal reaction kettle, crystallize at 200°C for 48h, cool at room temperature, and dissolve the solid The crystallized product is separated from the mother liquor, washed until neutral, dried, and calcined at 500-600°C in air for 6 hours to obtain the catalyst carrier SAPO-34 molecular sieve;

[0062] 3) adding manganese acetylacetonate O and cerium nitrate into acetone, fully stirring un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com