Method for synthesizing all-silicon Beta zeolite molecular sieve by sodium-free solvent-free route

A beta zeolite, solvent-free technology, applied in the field of molecular sieve preparation, can solve the problems of increasing synthesis complexity, large amount of template agent, etc., and achieves the effects of good crystallinity and purity, improved yield and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Synthesis of all-silicon Beta zeolite molecular sieves by a sodium-free and solvent-free route

[0022] 1.6g of solid silica gel, 1.0g of tetraethylammonium hydroxide (T, mass fraction 50%) and 5% all-silicon Beta zeolite molecular sieve seed crystals were placed in a mortar and ground for 10min, and then the reaction materials were added to polytetrafluoroethylene stainless steel In the reaction kettle, crystallize at 140°C for 2 days to complete the crystallization, and the product is suction filtered and dried to obtain the product. The ratio of the reaction raw materials is as follows: SiO 2 :0.15T.

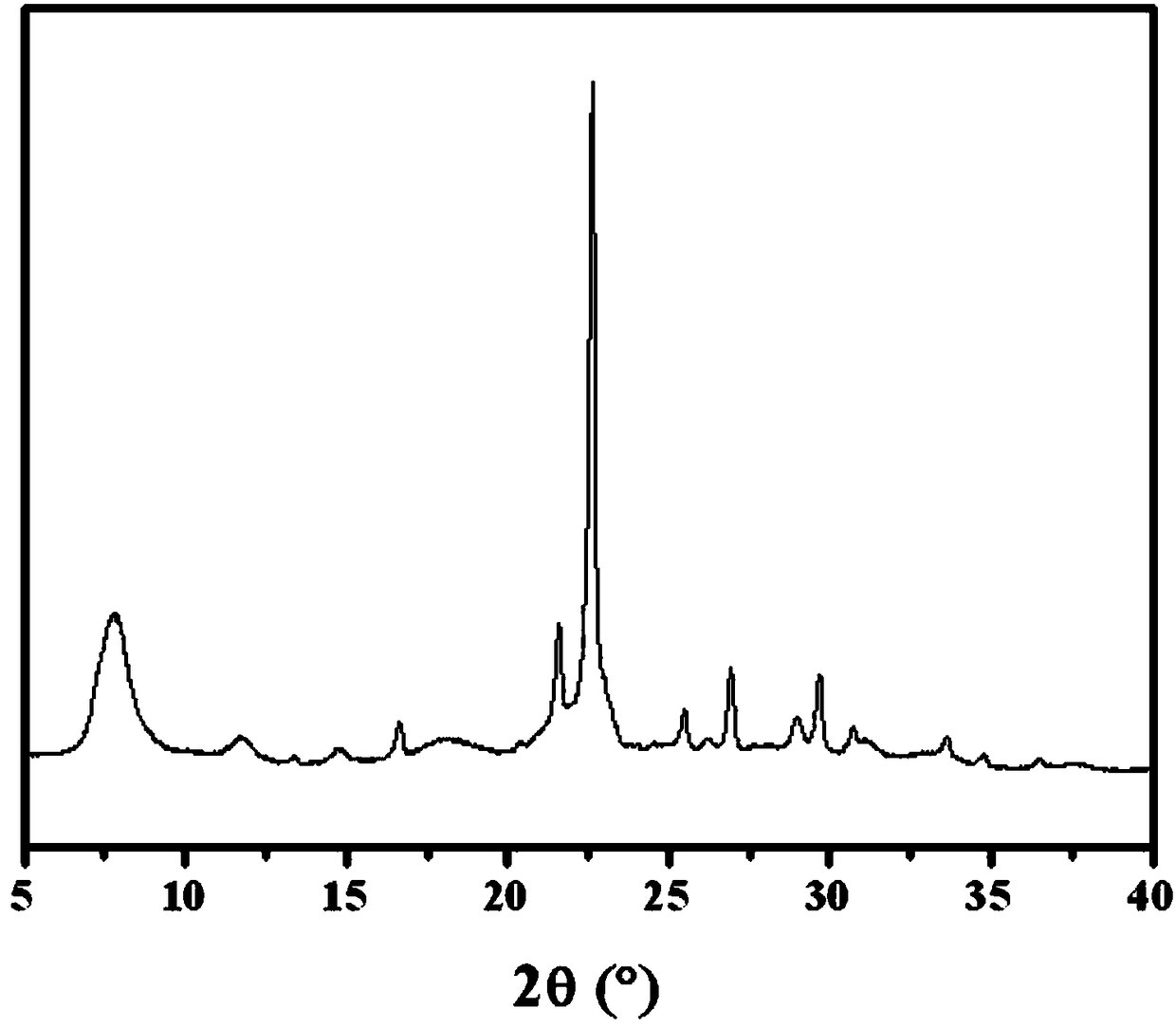

[0023] According to X-ray diffraction analysis, its structure is an all-silicon Beta zeolite molecular sieve such as figure 1 As shown, and through the scanning electron microscope photos, it can be seen that the synthesized product presents a sheet-like morphology, with a thickness of 100-150nm and a length of about 600nm. figure 2 shown.

Embodiment 2

[0024] Example 2: High-temperature synthesis of all-silicon Beta zeolite molecular sieve by a sodium-free and solvent-free route

[0025] 1.6g of solid silica gel, 1.67g of tetraethylammonium hydroxide (T, mass fraction 50%) and 10% all-silicon Beta zeolite molecular sieve seed crystals were placed in a mortar and ground for 10min, and then the reaction raw materials were added to polytetrafluoroethylene stainless steel In the reaction kettle, crystallize at 240°C for 1 hour to complete the crystallization, and the product is filtered with suction and dried to obtain the product. The ratio of the reaction raw materials is as follows: SiO 2 :0.25T.

Embodiment 3

[0026] Example 3: Low-temperature synthesis of all-silicon Beta zeolite molecular sieve by a sodium-free and solvent-free route

[0027] 1.6g of solid silica gel, 1.34g of tetraethylammonium hydroxide (T, mass fraction 50%) and 1% all-silicon Beta zeolite molecular sieve seed crystals were placed in a mortar and ground for 10min, and then the reaction materials were added to polytetrafluoroethylene stainless steel In the reaction kettle, crystallize at 100°C for 6 days to complete the crystallization, and the product is suction filtered and dried to obtain the product. The ratio of the reaction raw materials is as follows: SiO 2 :0.2T.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com