Method for green and efficient preparation of graphite phase carbon nitride nanosheet and application

A technology of graphitic carbon nitride and nanosheets, applied in chemical instruments and methods, catalyst activation/preparation, inorganic chemistry, etc. To improve the photocatalytic performance, reduce the synthesis cost, and improve the separation of electrons and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

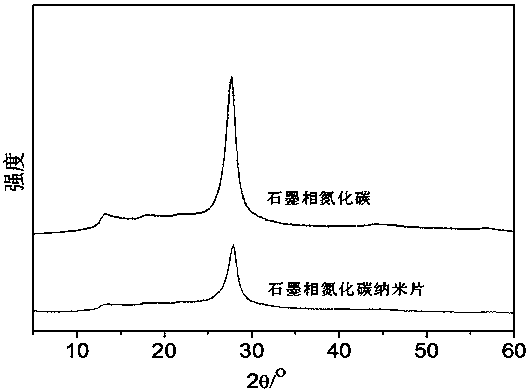

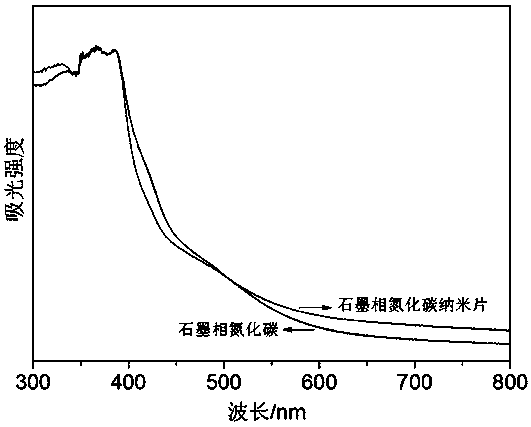

[0023] (1) Take 10 g of melamine and add it to a ceramic crucible with a cover, and carry out high-temperature polymerization in a muffle furnace. The polymerization temperature is 550 ° C, and the temperature is kept at a constant temperature for three hours. Yellow powder, graphite phase carbon nitride;

[0024] (2) Take 0.3 g of the above-mentioned graphitic carbon nitride, disperse it into 100 mL of water, add 0.5 mL of chloroplatinic acid (the concentration of chloroplatinic acid is 1 g / 100 mL), and irradiate with a xenon lamp light source for 4 h after vacuuming. 15°C; after the reaction is completed, the above sample is washed with ethanol and water to obtain Pt / graphite phase carbon nitride;

[0025] (3) Take 0.2 g of Pt / graphite-phase carbon nitride prepared in step 2), and feed water vapor / Ar mixed gas into the tube furnace, the flow rate of the mixed gas is 100 mL / min, and the pumping amount of water vapor is (6 mL / h), the flow rate of argon was (99.9 mL / min); the ...

Embodiment 2

[0028] (1) Take 10 g of melamine and add it to a ceramic crucible with a cover, and carry out high-temperature polymerization in a muffle furnace. The polymerization temperature is 550 ° C, and the temperature is kept at a constant temperature for three hours. After cooling, a yellow bulk graphite phase carbon nitride is obtained; the sample is ground to obtain Yellow powder, graphite phase carbon nitride;

[0029] (2) Take 0.3 g of the above-mentioned graphitic carbon nitride, disperse it into 100 mL of water, add 0.5 mL of chloroplatinic acid (the concentration of chloroplatinic acid is 1 g / 100 mL), and irradiate with a xenon lamp light source for 4 h after vacuuming. (12 ℃); after the reaction is completed, the above samples are washed with ethanol and water to obtain Pt / graphite carbon nitride;

[0030] (3) Take 0.3 g of Pt / graphite-phase carbon nitride prepared in step 2), and feed water vapor / Ar mixed gas into the tube furnace, the flow rate of the mixed gas is 100 mL / mi...

Embodiment 3

[0032] (1) Take 10 g of melamine and add it to a ceramic crucible with a cover, and carry out high-temperature polymerization in a muffle furnace. The polymerization temperature is 550 ° C, and the temperature is kept at a constant temperature for three hours. After cooling, a yellow bulk graphite phase carbon nitride is obtained; the sample is ground to obtain Yellow powder, graphite phase carbon nitride;

[0033] (2) Take 0.3 g of the above graphitic carbon nitride, disperse it into 100 mL of water, add 0.5 mL of chloroplatinic acid (the concentration of chloroplatinic acid is 1 g / 100 mL), and irradiate with xenon light source for 4 hours after vacuuming. The reaction temperature is (18°C); after the reaction was completed, the above samples were washed with ethanol and water to obtain Pt / graphite phase carbon nitride;

[0034] (3) Take 0.3 g of Pt / graphite-phase carbon nitride prepared in step 2), and feed water vapor / Ar mixed gas into the tube furnace, the flow rate of the...

PUM

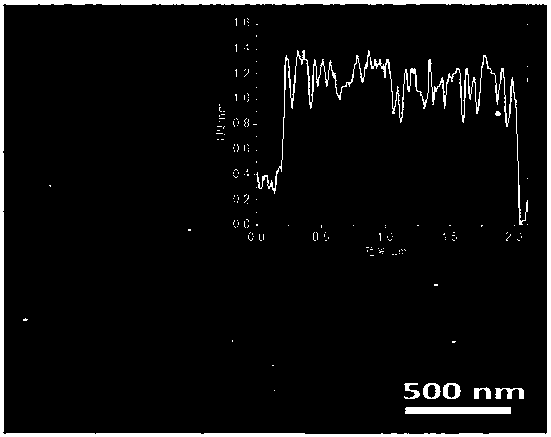

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com