A green and efficient method and application for preparing graphitic carbon nitride nanosheets

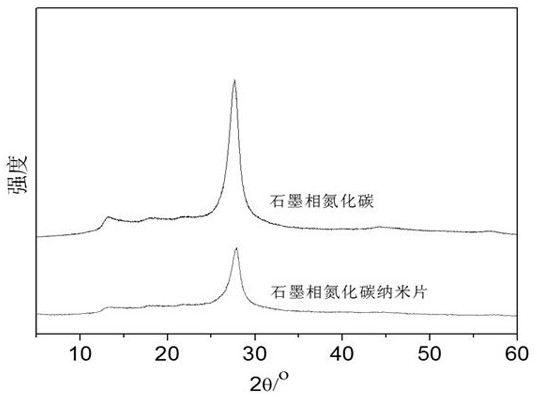

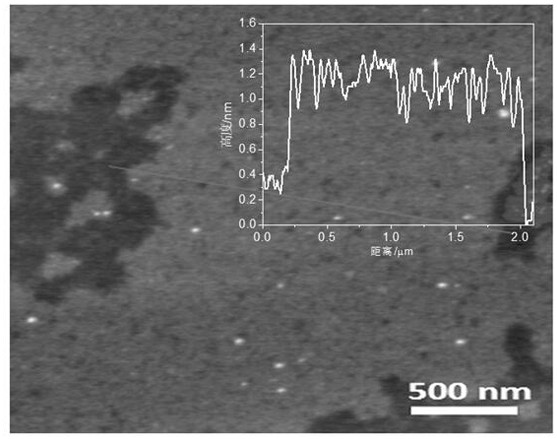

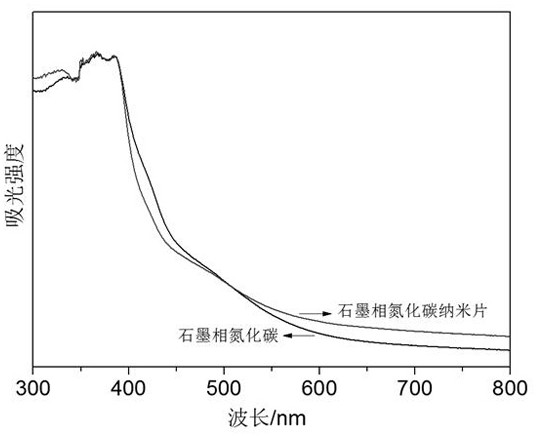

A graphitic carbon nitride and nanosheet technology, which is applied in chemical instruments and methods, catalyst activation/preparation, hydrogen production, etc., can solve the problem of low synthetic yield of graphitic carbon nitride nanosheets, pollution in the preparation process, etc. problems such as poor controllability, to achieve the effects of easy large-scale preparation, improved photocatalytic performance, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 10 g of melamine and add it to a ceramic crucible with a cover, and carry out high-temperature polymerization in a muffle furnace. The polymerization temperature is 550 ° C, and the temperature is kept at a constant temperature for three hours. After cooling, a yellow bulk graphite phase carbon nitride is obtained; the sample is ground to obtain Yellow powder, graphite phase carbon nitride;

[0024] (2) Take 0.3 g of the above-mentioned graphitic carbon nitride, disperse it into 100 mL of water, add 0.5 mL of chloroplatinic acid (the concentration of chloroplatinic acid is 1 g / 100 mL), and irradiate with a xenon lamp light source for 4 h after vacuuming. 15°C; after the reaction is completed, the above sample is washed with ethanol and water to obtain Pt / graphite phase carbon nitride;

[0025] (3) Take 0.2 g of Pt / graphite-phase carbon nitride prepared in step 2), and feed water vapor / Ar mixed gas into the tube furnace, the flow rate of the mixed gas is 100 mL / ...

Embodiment 2

[0028] (1) Take 10 g of melamine and add it to a ceramic crucible with a cover, and carry out high-temperature polymerization in a muffle furnace. The polymerization temperature is 550 ° C, and the temperature is kept at a constant temperature for three hours. After cooling, a yellow bulk graphite phase carbon nitride is obtained; the sample is ground to obtain Yellow powder, graphite phase carbon nitride;

[0029] (2) Take 0.3 g of the above-mentioned graphitic carbon nitride, disperse it into 100 mL of water, add 0.5 mL of chloroplatinic acid (the concentration of chloroplatinic acid is 1 g / 100 mL), and irradiate with a xenon lamp light source for 4 h after vacuuming. (12 ℃); after the reaction is completed, the above samples are washed with ethanol and water to obtain Pt / graphite carbon nitride;

[0030] (3) Take 0.3 g of Pt / graphite-phase carbon nitride prepared in step 2), and feed water vapor / Ar mixed gas into the tube furnace, the flow rate of the mixed gas is 100 mL / mi...

Embodiment 3

[0032] (1) Take 10 g of melamine and add it to a ceramic crucible with a cover, and carry out high-temperature polymerization in a muffle furnace. The polymerization temperature is 550 ° C, and the temperature is kept at a constant temperature for three hours. After cooling, a yellow bulk graphite phase carbon nitride is obtained; the sample is ground to obtain Yellow powder, graphite phase carbon nitride;

[0033] (2) Take 0.3 g of the above graphitic carbon nitride, disperse it into 100 mL of water, add 0.5 mL of chloroplatinic acid (the concentration of chloroplatinic acid is 1 g / 100 mL), and irradiate with xenon light source for 4 hours after vacuuming. The reaction temperature is (18°C); after the reaction was completed, the above samples were washed with ethanol and water to obtain Pt / graphite phase carbon nitride;

[0034] (3) Take 0.3 g of Pt / graphite-phase carbon nitride prepared in step 2), and feed water vapor / Ar mixed gas into the tube furnace, the flow rate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com