Full-valent organic compound fertilizer for alfalfa and preparation method thereof

A compound fertilizer and full-price technology, applied in the field of fertilizers, can solve problems such as residual toxins, nutrient imbalance, environmental pollution, etc., and achieve the effects of enhanced decomposition and transformation and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

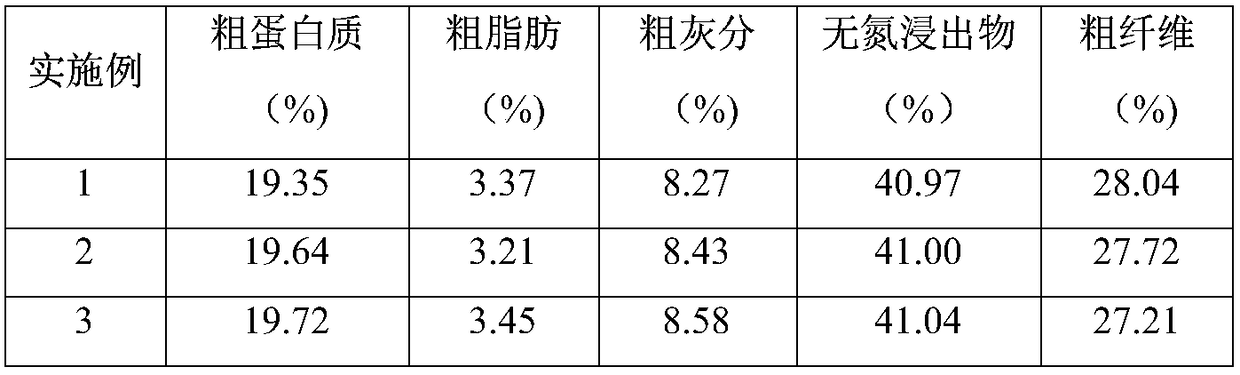

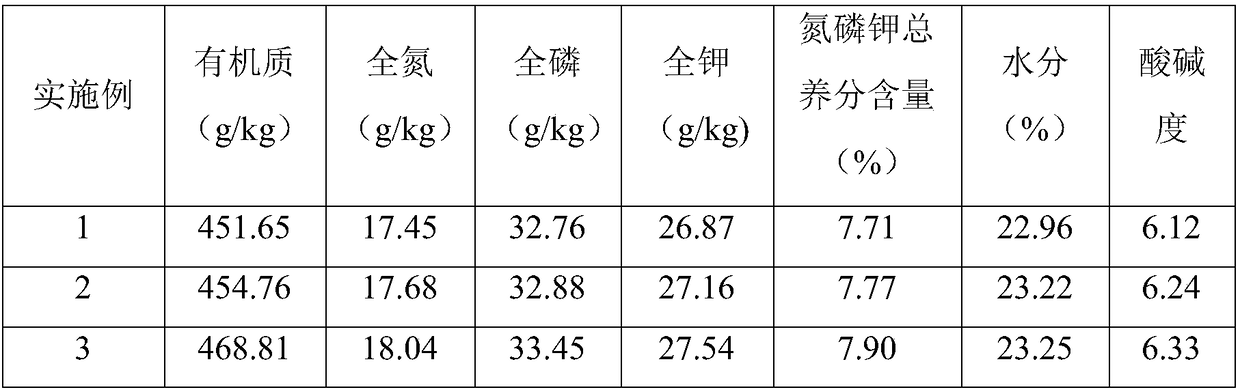

Embodiment 1

[0026] An alfalfa full-priced organic compound fertilizer, comprising the following raw materials by weight: 50 parts of wheat straw, 40 parts of cow dung, 0.01 part of trace elements, 1.0 part of bacillus, 2.0 parts of lactic acid bacteria, 2.5 parts of yeast, 0.5 part of cellulase, 1.0 part of hemicellulase; trace elements include raw materials in the following weight ratio: ferrous sulfate 3: zinc sulfate 1: ammonium molybdate 3: boric acid 3.

[0027] The preparation method of alfalfa full price organic compound fertilizer comprises the following steps:

[0028] (1) select the wheat straw that is harvested during the harvest period, and be crushed into 2-3cm wheat straw particles with a silage machine;

[0029] (2) add fresh cow dung to the wheat straw granules and mix well;

[0030] (3) The mixed material of step (2) is pulverized by a ball mill;

[0031] (4) adding the mixed material of step (3) to bacillus, lactic acid bacteria, yeast, cellulase, and hemicellulase to ...

Embodiment 2

[0035] An alfalfa full-priced organic compound fertilizer, comprising the following raw materials by weight: 50 parts of wheat straw, 50 parts of cow dung, 0.01 part of trace elements, 1.5 parts of bacillus, 2.5 parts of lactic acid bacteria, 2.5 parts of yeast, 0.5 part of cellulase, 1.0 parts of hemicellulase; trace elements include raw materials in the following weight ratio: ferrous sulfate 3: zinc sulfate 2: ammonium molybdate 2: boric acid 3.

[0036] The preparation method of fertilizer is the same as embodiment 1.

Embodiment 3

[0038] An alfalfa full-priced organic compound fertilizer, comprising the following raw materials by weight: 50 parts of wheat straw, 55 parts of cow dung, 0.01 part of trace elements, 1.5 parts of bacillus, 2.0 parts of lactic acid bacteria, 2.0 parts of yeast, 1.0 part of cellulase, 1.5 parts of hemicellulase; trace elements include raw materials in the following weight ratio: ferrous sulfate 4: zinc sulfate 2: ammonium molybdate 2: boric acid 2.

[0039] The preparation method of fertilizer is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com