Preparation method of hollow Ag-Au alloy complex structure micro-nano array

A composite structure and alloy technology, applied in nanotechnology, nanotechnology, metal material coating technology and other directions, can solve the problems of easy aggregation of nanoparticles, affecting the detection effect, difficult to control the gap, etc., to achieve simple and feasible operation, uniform array arrangement , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a hollow Ag-Au alloy composite structure micro-nano array, comprising the following steps:

[0047] S1: Prepare an ordered PS single-layer colloidal sphere template based on Au / ITO to obtain a PS / Au / ITO substrate;

[0048] S1-1: Coating a 10nm-thick Au film on ITO glass with an ion sputtering coater; sputtering current 20mA, time 90s;

[0049] S1-2: Obtain a periodic and ordered PS single-layer colloidal sphere template with a centimeter-scale large area on a glass sheet through the gas-liquid interface self-assembly method, and the diameter of the PS is 1000nm;

[0050] S1-3: Transfer the prepared PS monolayer colloidal spheres onto the Au / ITO substrate as a whole by the suspension method, and after drying naturally, heat them in an oven at 110°C for 5 minutes to make the PSs spheres firmly adhere to the Au / ITO on the base;

[0051] S1-4: PS / Au / ITO substrate cut into 1cm×3cm.

[0052] S2: Composite Ag film on the PS / Au / ITO substrate obtained i...

Embodiment 2

[0066] The hollow Ag-Au alloy composite structure micro-nano array sample obtained in Example 1 was used as the SERS substrate, and its detection performance for melamine solution was tested.

[0067] Raman spectra were collected by a confocal Raman spectrometer (Renishaw inVia Reflex). Acquisition conditions: 785nm wavelength, power 2mW, 50x microscope to focus the laser beam on the sample to form a spot with a diameter of about 2μm. The spectrum acquisition time is 10s. Before Raman spectrum detection, the prepared SERS substrate samples were soaked in melamine solution for 2 h to ensure that melamine was fully adsorbed on the samples. Then it was washed with deionized water to remove excess melamine molecules, and measured after air drying.

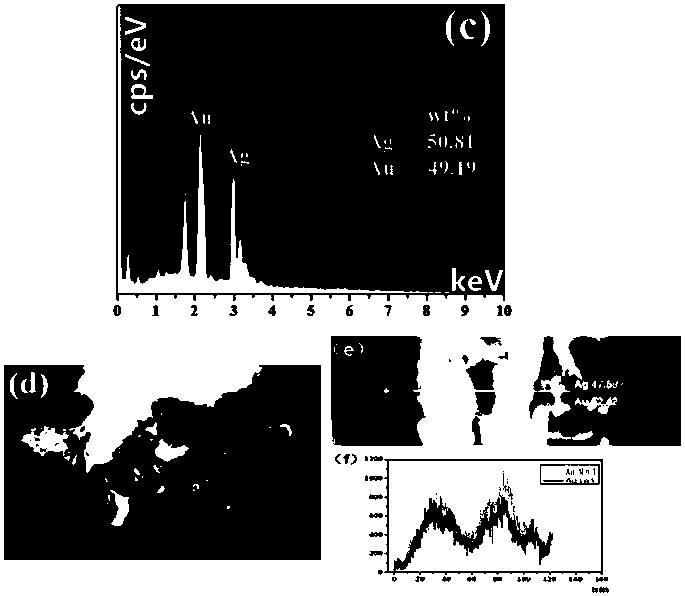

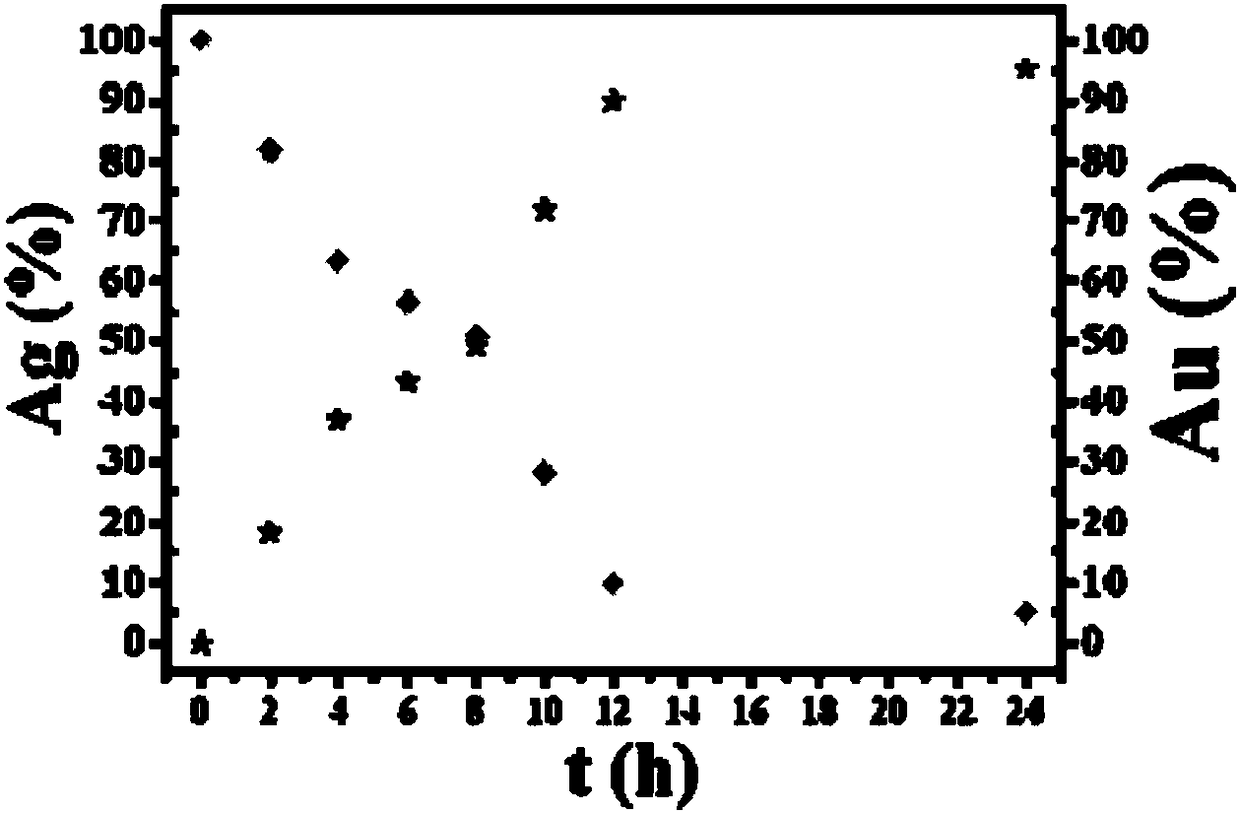

[0068] Firstly, BPHAN arrays with different etching times (i.e. different Ag-Au ratios) were tested against concentrations of 10 -5 The SERS spectral signal of M concentration, such as Figure 4 (a) shown. It can be seen from the ...

Embodiment 3

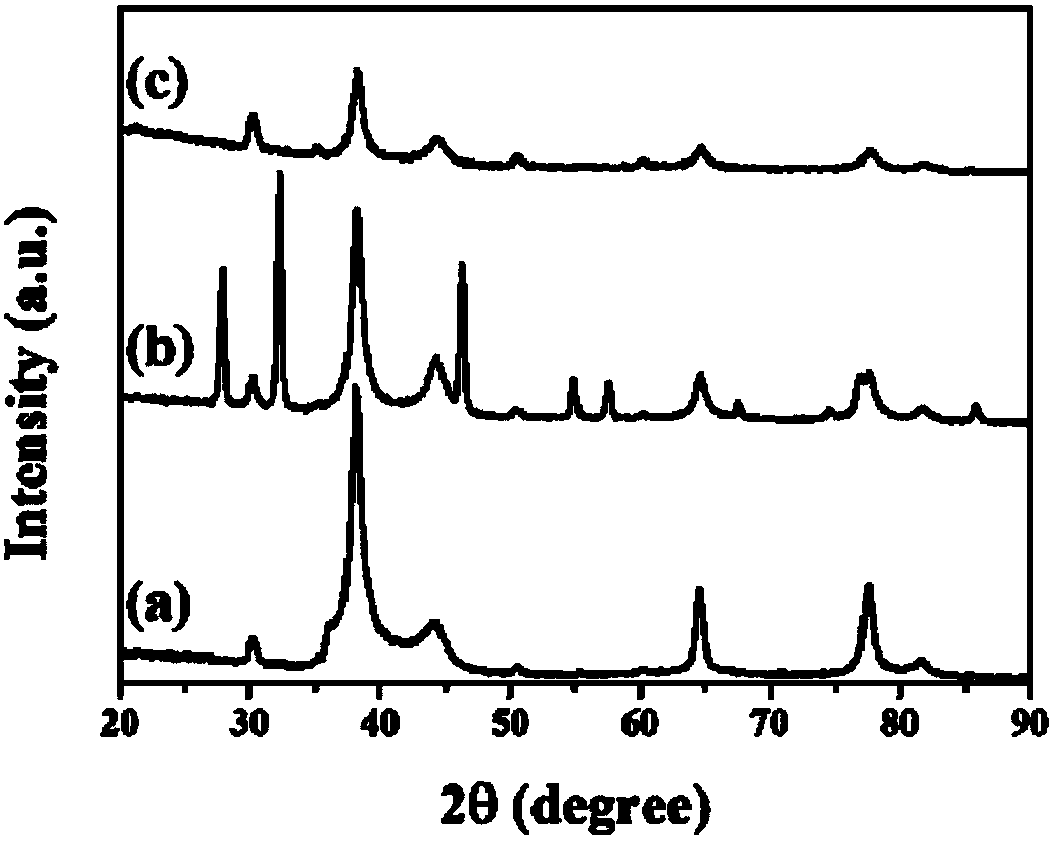

[0071] In order to clearly understand the physical mechanism of SERS enhancement of hollow Ag-Au alloy composite structure micro-nano arrays, the present invention analyzes the local electric field characteristics of three kinds of bowl-like structure arrays. Parameter setting: The maximum diameter of the mouth of the bowl is 976nm, the period is 1000nm, and it has a hexagonal close-packed structure. The parameters come from image 3 The observation results of the SEM image in the middle; three bowl-shaped structures using three different materials, namely gold, silver, and Ag 0.5 Au 0.5 alloy, wherein the dielectric constant of the Ag-Au alloy material is obtained by using the equivalent dielectric constant. The light source whose polarization direction of the electric field is along the x-axis is incident vertically on the surface, and the wavelength of the light source is 785nm of the pump light of the Raman spectrum.

[0072] Figure 6 They are Au, Ag, and Ag 0.5 Au 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com