Wheat special fertilizer and preparation method thereof

A technology of special fertilizer and wheat, which is applied in the field of special fertilizer for wheat and its manufacture, can solve the problems of environmental threat, decrease of fertilizer utilization rate, increase of cost, etc., and achieve the effects of low operating cost, improvement of fertilizer utilization rate and promotion of corn growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

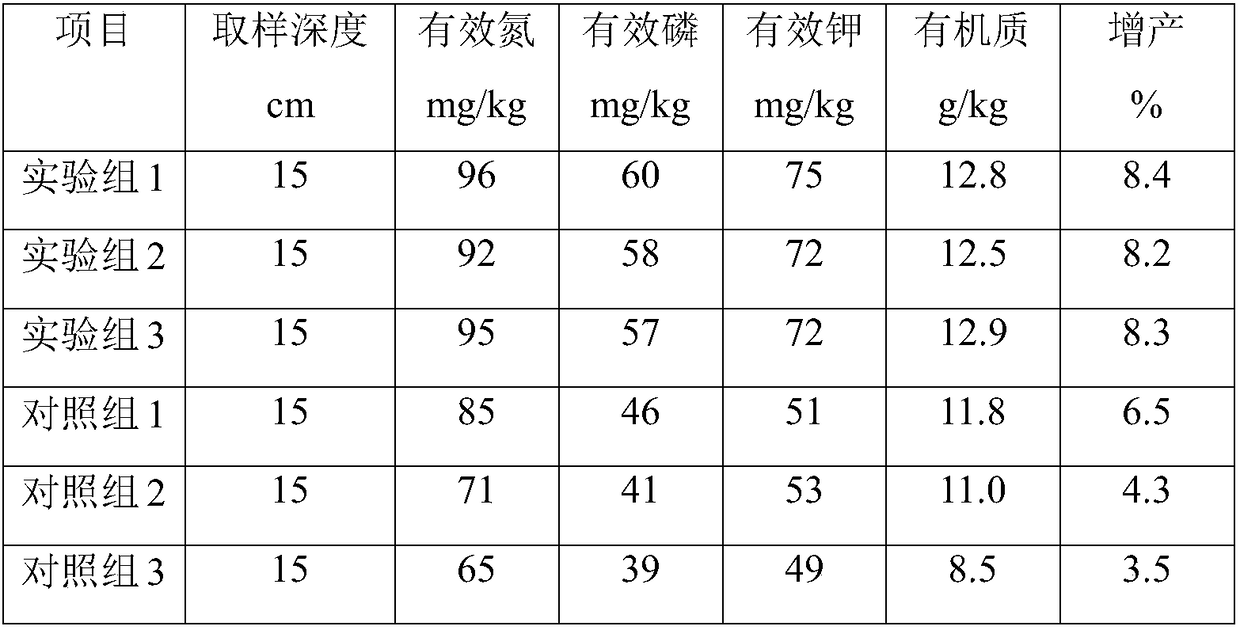

Examples

Embodiment 1

[0036] A special fertilizer for wheat is prepared from the following raw materials in parts by weight: 100 parts of urea, 25 parts of ammonium sulfate, 25 parts of superphosphate, 20 parts of potassium dihydrogen phosphate, 15 parts of potassium sulfate, 7 parts of zinc sulfate, molybdenum 7 parts of ammonium acid, 13 parts of trace elements, 1 part of dispersion accelerator, 70 parts of fermented fertilizer, 35 parts of bentonite, 3 parts of porous magnetic chitosan microspheres;

[0037] The dispersion accelerator is prepared from sodium hexametaphosphate, sodium methacrylate and polyethylene glycol monomethyl ether methacrylate in a weight ratio of 1:1:1;

[0038] Described porous magnetic chitosan microsphere is made by following steps:

[0039] 1) Mix ammonia water, nano ferric oxide, carboxymethyl chitosan and Tween-20 evenly, seal and soak for 3 hours, heat in a water bath at 53°C and stir until carboxymethyl chitosan is completely dissolved, and stand still until bubbl...

Embodiment 2

[0059] A special fertilizer for wheat is prepared from the following raw materials in parts by weight: 100 parts of urea, 30 parts of ammonium sulfate, 20 parts of superphosphate, 15 parts of potassium dihydrogen phosphate, 20 parts of potassium sulfate, 5 parts of zinc sulfate, molybdenum 8 parts of ammonium acid, 10 parts of trace elements, 2 parts of dispersion accelerator, 60 parts of fermented fertilizer, 45 parts of bentonite, 2 parts of porous magnetic chitosan microspheres;

[0060] The dispersion accelerator is prepared from sodium hexametaphosphate, sodium methacrylate and polyethylene glycol monomethyl ether methacrylate in a weight ratio of 1:0.8:1.5;

[0061] Described porous magnetic chitosan microsphere is made by following steps:

[0062] 1) Mix ammonia water, nano ferric oxide, carboxymethyl chitosan and Tween-20 evenly, seal and soak for 2 hours, heat in a water bath at 50°C and stir until carboxymethyl chitosan is completely dissolved, and stand still until ...

Embodiment 3

[0070] A special fertilizer for wheat is prepared from the following raw materials in parts by weight: 100 parts of urea, 20 parts of ammonium sulfate, 30 parts of superphosphate, 25 parts of potassium dihydrogen phosphate, 10 parts of potassium sulfate, 9 parts of zinc sulfate, molybdenum 6 parts of ammonium acid, 15 parts of trace elements, 2 parts of dispersion accelerator, 80 parts of fermented fertilizer, 25 parts of bentonite, 2 parts of porous magnetic chitosan microspheres;

[0071] The dispersion accelerator is prepared from sodium hexametaphosphate, sodium methacrylate and polyethylene glycol monomethyl ether methacrylate in a weight ratio of 1:1.2:0.5;

[0072] Described porous magnetic chitosan microsphere is made by following steps:

[0073] 1) Mix ammonia water, nano ferric oxide, carboxymethyl chitosan and Tween-20 evenly, seal and soak for 4 hours, heat and stir in a water bath at 55°C until carboxymethyl chitosan is completely dissolved, and stand still until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com