Antifouling composite coating film, antifouling substrate, and method for manufacturing antifouling substrate

A technology of anti-fouling and fouling coatings, applied in anti-fouling/underwater coatings, chemical instruments and methods, and devices for coating liquids on surfaces, etc., which can solve the problems of increased surface roughness, reduced ship speed, and increased fuel costs and other problems, to achieve the effect of excellent damage resistance and adhesion, excellent damage resistance and long-term adhesion, and shorten the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

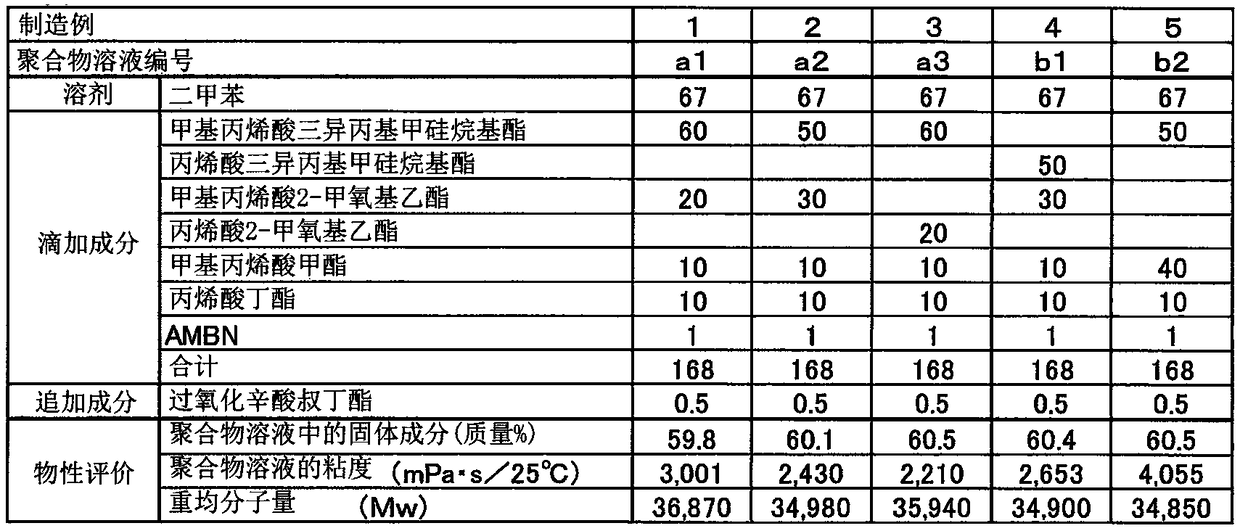

[0215] Add 53 parts by mass xylene in the reaction vessel equipped with stirrer, reflux condenser, thermometer, nitrogen inlet pipe and dropping funnel, while stirring the xylene with stirrer under nitrogen atmosphere, under normal pressure, put the xylene in the reaction vessel Xylene was heated to 85°C. While maintaining the temperature of xylene in the reaction vessel at 85° C., 60 parts by mass of TIPSMA (triisopropylsilyl methacrylate), MEMA (2-methylmethacrylate oxyethyl ester) 20 parts by mass and MMA (methyl methacrylate) 10 parts by mass, BA (butyl acrylate) 10 parts by mass and AMBN (2,2'-azobis(2-methylbutyronitrile)) 1 part by mass of the formed monomer mixture was added to the reaction vessel.

[0216] Next, 0.5 parts by mass of tert-butyl peroxyoctanoate was further added to the reaction vessel, and while the liquid temperature in the reaction vessel was kept at 85° C. under normal pressure, the liquid in the reaction vessel was continuously stirred for two hour...

manufacture example 2~5

[0218] Except using the monomer mixture having the composition shown in Table 1 instead of the monomer mixture used in Production Example 1, polymer solutions (a2), (a3), ( b1) and (b2), various physical properties were measured. The results are shown in Table 1.

[0219] [Table 1]

manufacture example 6

[0222] [Manufacture example 6] Manufacture of gum rosin copper salt

[0223] Into a 1,000ml flask equipped with a thermometer, a reflux condenser, a stirrer, and a thermometer, 400g of a xylene solution (solid content 50%) of Chinese gum rosin (WW rosin, acid value 172), 200g of cuprous oxide, 100g of methanol, and glass beads were added. (diameter 2.5-3.5mm), after stirring at 70-80 degreeC for 8 hours, it kept at the temperature of 50 degreeC for 2 days. Then, after cooling the obtained mixed solution to room temperature (25 degreeC) and filtering, the methanol component was distilled off by concentration under reduced pressure. Thereafter, xylene was added to the obtained concentrate to obtain a xylene solution of gum rosin copper salt (dark blue transparent solution, solid content about 50%). The xylene solution of the obtained gum rosin copper salt had a residual component after heating of 50.8%. This gum rosin copper salt was used in Comparative Example 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| stripping area | aaaaa | aaaaa |

| stripping area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com