Preparation method of spherical micron-size gamma-aluminium oxide carrier for preparing hydrogen peroxide by anthraquinone hydrogenation

An aluminum oxide, quasi-spherical technology, applied in the preparation of organic compounds, quinone preparation, chemical instruments and methods, etc., can solve problems such as complicated steps, and achieve the effects of low preparation cost, high specific surface area, and high hydrogenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

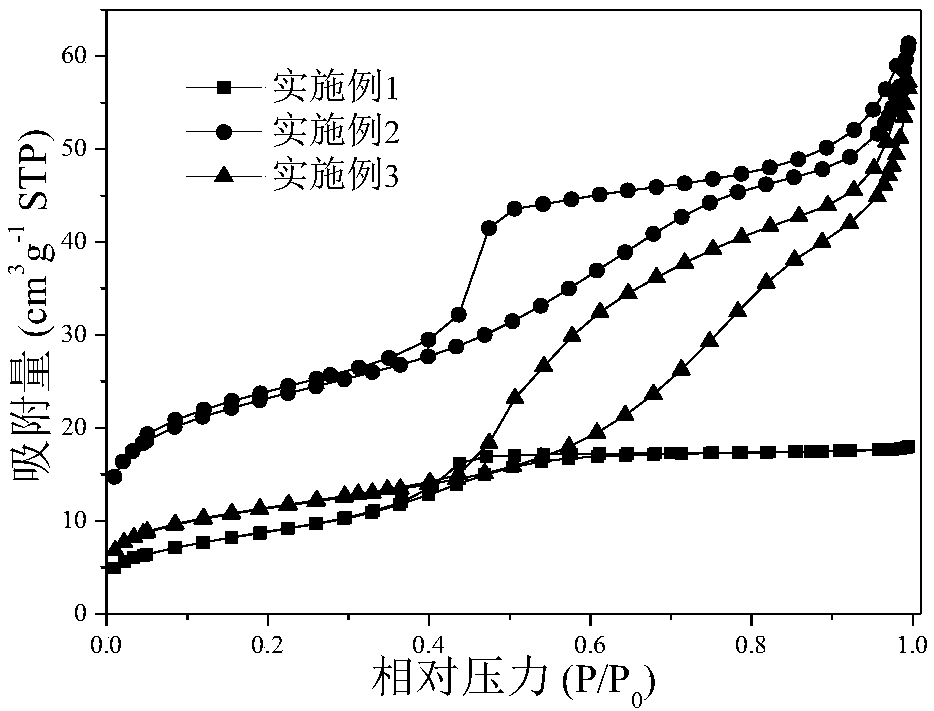

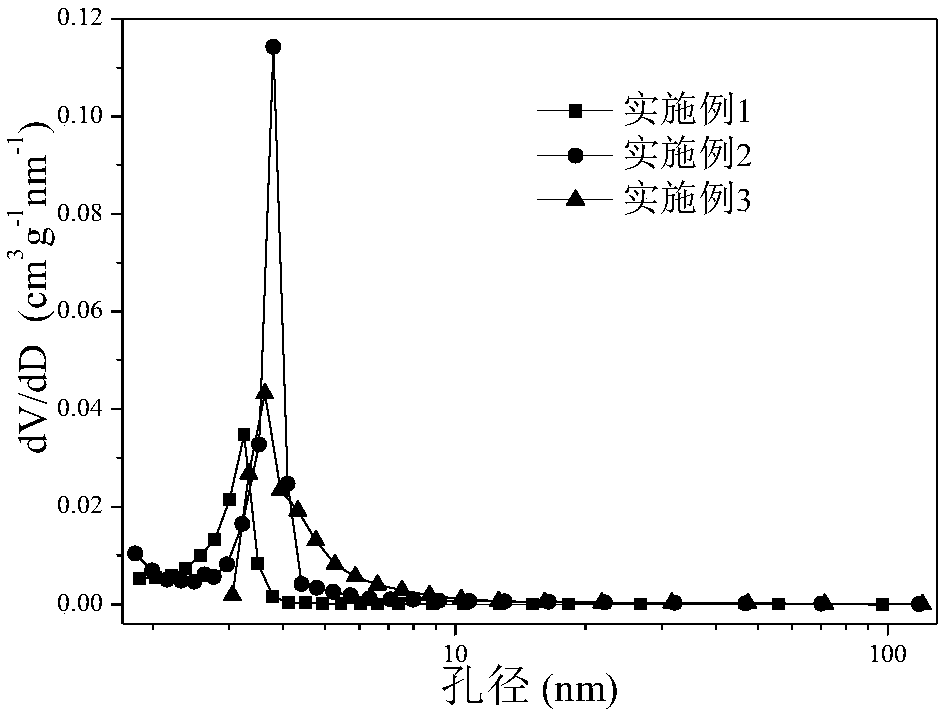

Embodiment 1

[0035] (1) 0.036mol anhydrous glucose and 0.018mol Al(NO 3 ) 3 9H 2 O was dispersed in 90 mL of deionized water (the molar ratio of the two was 2:1), ultrasonicated for 10 min (ultrasonic power 100 W), 10 mL of 0.2 mol / L urea solution was added as a precipitant, stirred for 30 min, and hydrothermally heated at 180 °C 8h, filter the obtained black product, and alternately wash it with deionized water and absolute ethanol until the filtrate is clear, and dry it in a blast drying oven at 80°C for 8h to obtain fine and fluffy colloidal carbon / AlOOH composite material powder body. The powder was calcined in an air atmosphere at 550°C for 3h (heating rate 2°C / min) to obtain γ-Al 2 o 3 Powder.

[0036] (2) With the above γ-Al 2 o 3 The powder is used as a carrier, and the auxiliary component Ni is loaded by an equal-volume impregnation method, and 0.0594g Ni (NO 3 ) 2 ·6H 2 O is dissolved in 0.6g carrier corresponding to the saturated water absorption, and the obtained solu...

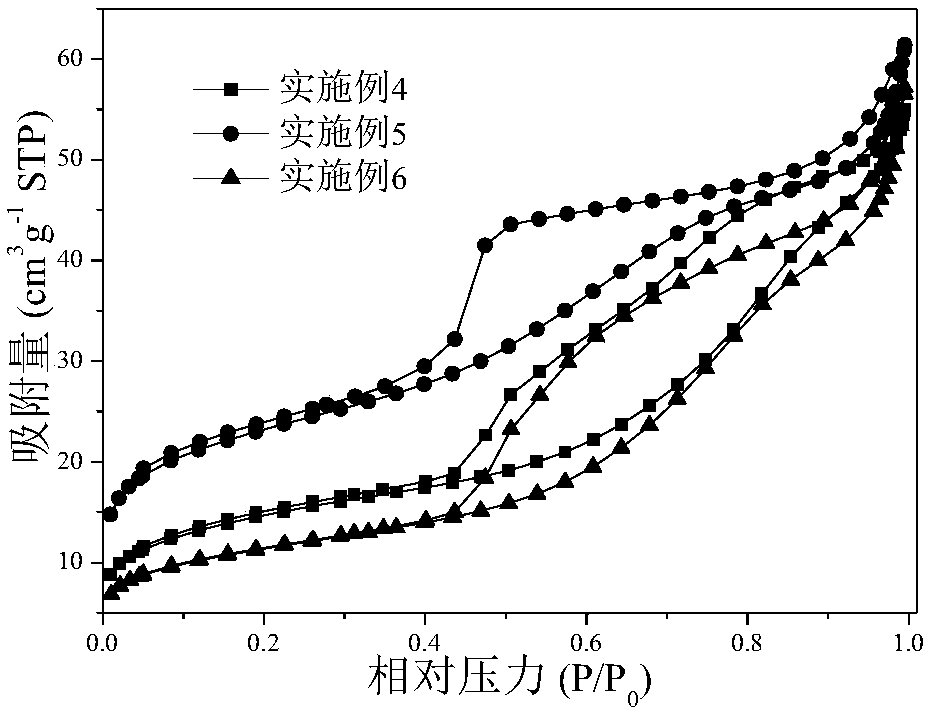

Embodiment 2

[0041] (1) 0.072mol anhydrous glucose and 0.018mol Al(NO 3 ) 3 9H 2 O was dispersed in 90 mL of deionized water (the molar ratio of the two was 4:1), ultrasonicated for 10 min (ultrasonic power 100 W), and 10 mL of 0.2 mol / L urea solution was added as a precipitant, stirred for 30 min, and hydrothermally heated at 180 °C 8h, filter the obtained black product, and alternately wash the filtrate with deionized water and absolute ethanol until the filtrate is clear, and dry it in a blast drying oven at 80°C for 8h to obtain a fine and fluffy colloidal carbon / AlOOH composite material powder . The powder was calcined in an air atmosphere at 550°C for 3h (heating rate 2°C / min) to obtain γ-Al 2 o 3 carrier.

[0042] (2) With the above γ-Al 2 o 3 The powder is the carrier, and the auxiliary component Fe is loaded by the equal-volume impregnation method, and 0.1298g Fe (NO 3 ) 3 9H 2 O is dissolved in 0.6g carrier corresponding to the saturated water absorption, and the obtain...

Embodiment 3

[0047] (1) 0.144mol anhydrous glucose and 0.018mol Al(NO 3 ) 3 9H 2 O was dispersed in 90 mL of deionized water (the molar ratio of the two was 8:1), ultrasonicated for 10 min (ultrasonic power 100 W), and 10 mL of 0.2 mol / L urea solution was added as a precipitant, stirred for 30 min, and hydrothermally heated at 180 °C 8h, filter the obtained black product, and alternately wash the filtrate with deionized water and absolute ethanol until the filtrate is clear, and dry it in a blast drying oven at 80°C for 8h to obtain fine and fluffy colloidal carbon / AlOOH composite powder . The powder was calcined in an air atmosphere at 550°C for 3h (heating rate 2°C / min) to obtain γ-Al 2 o 3 carrier.

[0048] (2) With the above γ-Al 2 o 3 The powder is used as a carrier, and the auxiliary component Zn is loaded by an equal volume impregnation method, and 0.1373g Zn (NO 3 ) 2 ·6H 2 O is dissolved in 0.6g carrier corresponding to the saturated water absorption, and the obtained so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com