Preparation method of novel water-based light-cured resin

A light-curable resin, water-based technology, applied in the field of preparation of new water-based light-curable resin, can solve the problems that polymer chains cannot be chemically cross-linked, reduce the drying rate of water-based resin, limit the cross-linking density of cured film, etc., and achieve high hardness , good reactivity, anti-polymerization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of novel aqueous photocurable resin in the present embodiment is as follows:

[0038] 1. Synthesis of diacrylate-monomethacrylate monomer

[0039] Weigh and mix 71.1g of glycidyl methacrylate and 36g of acrylic acid, add 0.21g of N,N-dimethylbenzylamine, slowly raise the temperature to 95°C until the acid value drops below 5mg KOH / g; Add 70mL of dichloromethane and 55.7g of triethylamine, add 49.8g of acryloyl chloride dropwise under a nitrogen atmosphere and an ice-water bath, the dropwise addition is completed within 1 hour, and then react at room temperature for 12 hours; remove the generated hydrochloride by filtration, and use Washed three times with saturated sodium bicarbonate solution, dried over anhydrous magnesium sulfate, filtered, and evaporated to dryness to obtain diacrylate-monomethacrylate monomer, 3-(methacryloyloxy)propyl-1,2- Diacrylate.

[0040] 2. Synthesis of thiourethane acrylate prepolymer

[0041] Under nitrogen atmospher...

Embodiment 2

[0048] The preparation method of novel aqueous photocurable resin in the present embodiment is as follows:

[0049] 1. Synthesis of diacrylate-monomethacrylate monomer

[0050] Weigh 85.7g of 4-glycidyloxybutyl methacrylate and 28.8g of acrylic acid and mix them, add 0.55g of triethylamine, slowly heat up to 95°C and react until the acid value drops below 5mg KOH / g; Add 60mL of dichloromethane and 81.5g of tri-n-decanine amine, dropwise add 39.8g of acryloyl chloride under nitrogen atmosphere and ice-water bath, dropwise add within 1 hour, then react at room temperature for 12 hours; remove the formed hydrochloride by filtration, Washed three times with saturated sodium bicarbonate solution, dried over anhydrous magnesium sulfate, filtered, and evaporated to dryness to obtain diacrylate-monomethacrylate monomer, 3-(methacryloyloxybutoxy)propyl- 1,2-Diacrylate.

[0051] 2. Synthesis of thiourethane acrylate prepolymer

[0052] Under a nitrogen atmosphere and an ice-water bat...

Embodiment 3

[0056] The preparation method of novel aqueous photocurable resin in the present embodiment is as follows:

[0057] 1. Synthesis of diacrylate-monomethacrylate monomer

[0058] Weigh 78.5g of 3,4-epoxycyclohexylmethyl methacrylate and 28.8g of acrylic acid and mix them, add 0.31g of tri-n-butylamine, slowly heat up to 95°C and react until the acid value drops below 5mg KOH / g; Add 60mL of dichloromethane and 44.5g of triethylamine to the reaction solution, add 39.8g of acryloyl chloride dropwise under a nitrogen atmosphere and an ice-water bath, and the dropwise addition is completed within 1 hour, and then react at room temperature for 12 hours; remove the generated hydrochloric acid by filtration salt, washed three times with saturated sodium bicarbonate solution, dried over anhydrous magnesium sulfate, filtered, and evaporated to dryness to obtain a diacrylate-monomethacrylate monomer, 3,4-diacryloyloxycyclohexyl methacrylate methyl ester.

[0059] 2. Synthesis of thiouret...

PUM

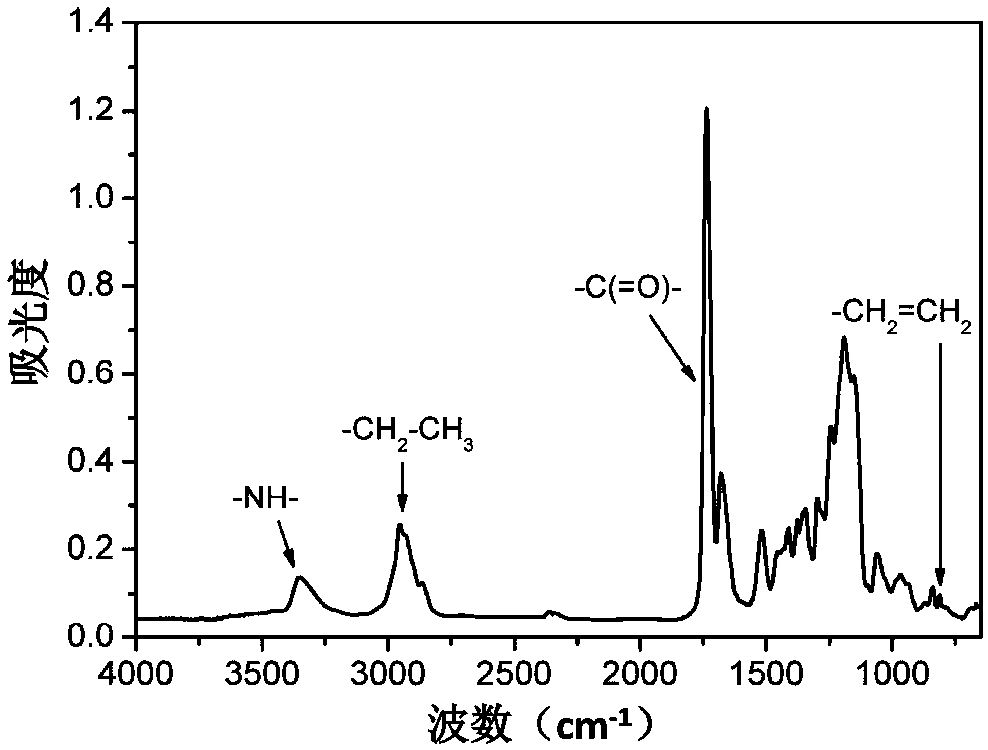

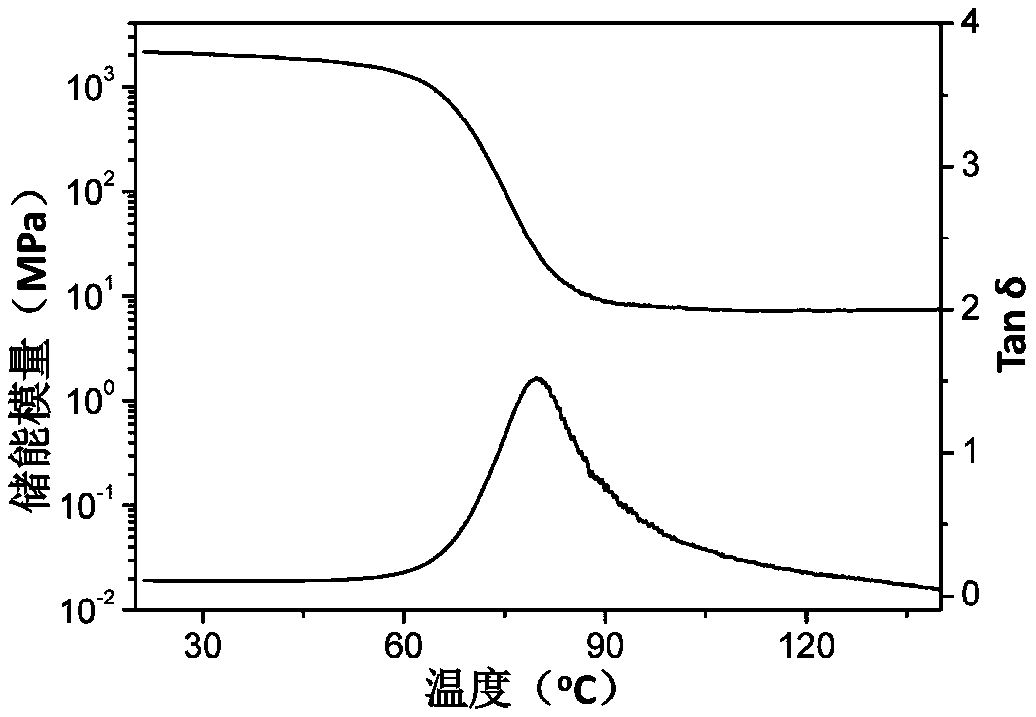

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com