Preparation method of PTA (pure terephthalic acid) with flame-retardant function

A functional and flame retardant modifier technology, applied in the field of PTA preparation, can solve the problems affecting polyester mechanics, poor mutual fusion, single PTA product, etc., to improve production efficiency and product quality, promote growth, and increase output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

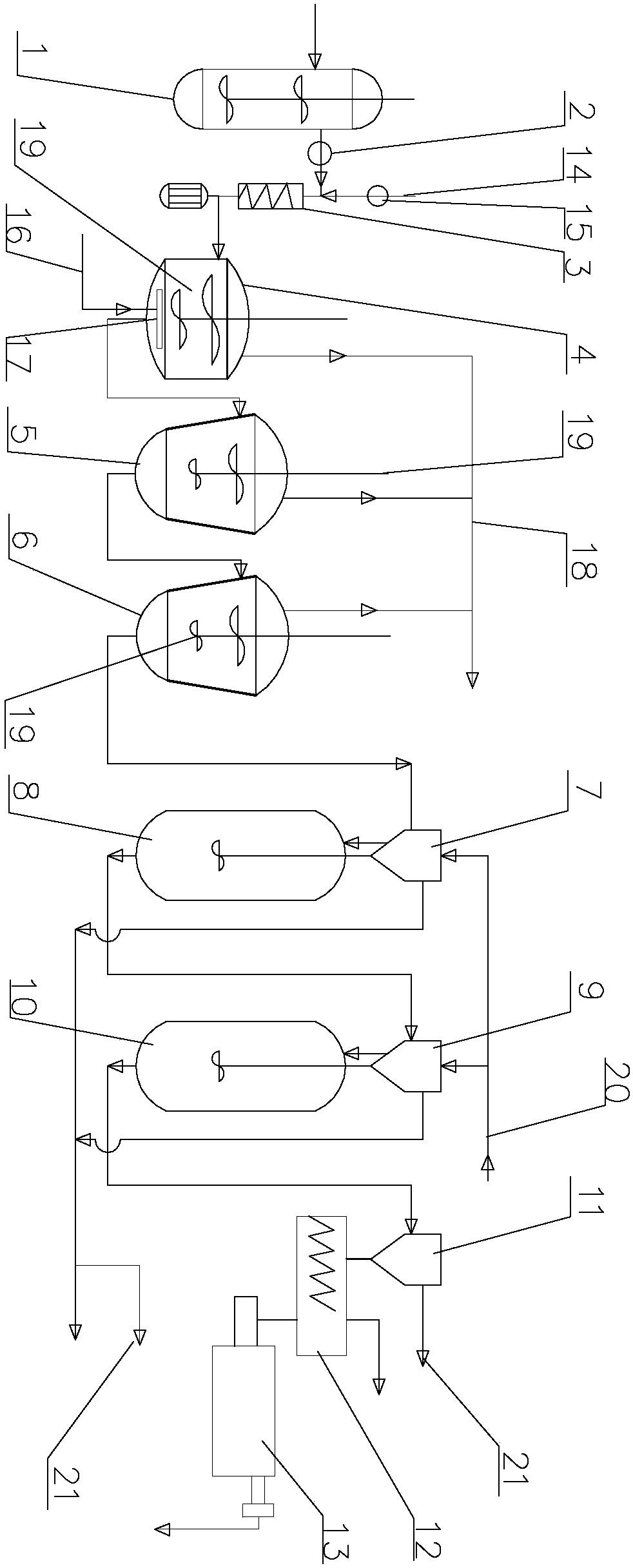

Image

Examples

Embodiment 1

[0037] A preparation method of PTA with flame retardant function, comprising the following steps:

[0038] 1) In parts by mass, 1 part of magnesium aluminum spinel, 1.3 parts of basic magnesium sulfate whiskers, 0.3 parts of nickel-iron spinel, 14 parts of 20wt% salicylic acid aqueous solution, 6 parts Mix oxyfluoric acid aqueous solution with a concentration of 10wt%, grind it with a liquid-phase high-energy ball mill (60°C, 2.5h), and then move it to a titanium-lined hydrothermal reactor for reaction (175°C, 2.5MPa, 11h) , then atomized and separated and dried, calcined (525°C, 4h), cooled to room temperature, then ground in a ball mill for 3h, moved to a stirred plasma reactor, and carried out radio frequency plasma treatment with nitrogen as a carrier gas (pressure 50Pa, power 55W, time 8min), then add it to 9 parts of 30wt% organic silicon ethanol solution, ultrasonically disperse (70°C, 1.5h), filter, fully wash with absolute ethanol, and then heat and dry , and passed ...

Embodiment 2

[0045] A preparation method of PTA with flame retardant function, comprising the following steps:

[0046] 1) In parts by mass, 0.8 parts of magnesium aluminum spinel, 1.6 parts of basic magnesium sulfate whiskers, 0.2 parts of nickel-iron spinel, 16 parts of 18wt% salicylic acid aqueous solution, 4 parts Aqueous hydrofluoric acid solution with a concentration of 12wt% was mixed, ground with a liquid-phase high-energy ball mill (50°C, 3h), and then moved to a titanium-lined hydrothermal reactor for reaction (150°C, 3MPa, 12h), and then Atomization separation and drying, calcination treatment (500°C, 5h), cooling to room temperature, grinding treatment in a ball mill for 2h, moving to a stirred plasma reactor, nitrogen as carrier gas, radio frequency plasma treatment (pressure 40Pa, power 80W, time 10min), then added to 8 parts of 32wt% organic silicon ethanol solution, ultrasonically dispersed (60°C, 2h), filtered, fully washed with absolute ethanol, then heated and dried, and...

Embodiment 3

[0053] A preparation method of PTA with flame retardant function, comprising the following steps:

[0054] 1) In parts by mass, 1.2 parts of magnesium aluminum spinel, 1.0 parts of basic magnesium sulfate whiskers, 0.4 parts of nickel-iron spinel, 12 parts of salicylic acid aqueous solution with a concentration of 22wt%, 8 parts The oxyfluoric acid aqueous solution with a concentration of 8wt% was mixed, ground with a liquid-phase high-energy ball mill (70°C, 2h), and then moved to a titanium-lined hydrothermal reactor for reaction (200°C, 2MPa, 10h), and then Atomization separation and drying, calcination treatment (550°C, 3h), cooling to room temperature, grinding treatment in a ball mill for 4h, moving to a stirred plasma reactor, nitrogen as carrier gas, radio frequency plasma treatment (pressure 60Pa, power 30W, time 5min), then added to 10 parts of 32wt% organic silicon ethanol solution, ultrasonically dispersed (80°C, 1h), filtered, fully washed with absolute ethanol, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com