High performance composite material for aerospace craft radar radome and preparation method thereof

A technology for radomes and aerospace vehicles, applied in the field of polymer materials, can solve problems such as low dielectric constant, and achieve the effects of low dielectric constant, low dielectric loss, and improved heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] One, embodiment 1 polyimide

[0025] The ratio of various components involved in polyimide

[0026] The components participating in the polyimide were polymerized according to the molar ratios in Table 1 to obtain polyimides I to III.

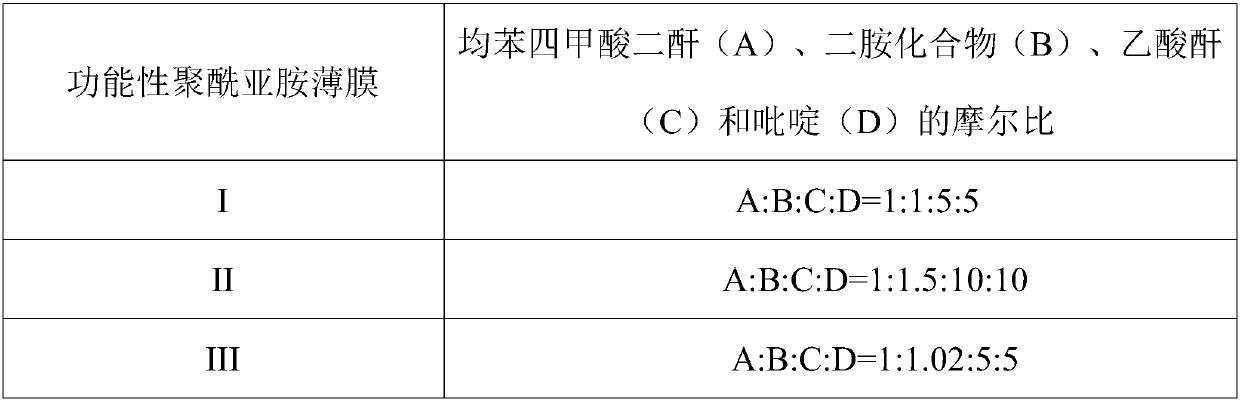

[0027] Table 1 Polyimides I-III polymerized by various components in different molar ratios

[0028]

Embodiment 2

[0029] The preparation of embodiment 2 high-performance composite material I

[0030] Step one, will and N,N-dimethylacetamide into the reaction kettle, feed high-purity nitrogen bubbles to remove oxygen, and stir until After dissolving, add dry pyromellitic dianhydride, pyromellitic dianhydride and The molar ratio is 1:1, The mass percent concentration of the sum of the mass of pyromellitic dianhydride and pyromellitic dianhydride in the reaction system is 15%, the temperature of the reaction system is controlled at 15-40°C, and the polymerization reaction is carried out for 5-30 hours to obtain polyamic acid;

[0031] Step 2. Add acetic anhydride and pyridine to the polyamic acid obtained in step 1. The molar ratio of pyromellitic dianhydride, acetic anhydride and pyridine is 1:5:5. Stir while raising the temperature. Raise the temperature to 60-85°C at a rate of 1 min, and carry out imidization reaction. After 12-24 hours of reaction, the reaction is completed, and t...

Embodiment 3

[0036] The preparation of embodiment 3 high-performance composite material II

[0037] Step one, will and N,N-dimethylacetamide into the reaction kettle, feed high-purity nitrogen bubbles to remove oxygen, and stir until After dissolving, add dry pyromellitic dianhydride, pyromellitic dianhydride and The molar ratio is 1:1.5, The mass percent concentration of the sum of the mass of pyromellitic dianhydride and pyromellitic dianhydride in the reaction system is 20%, the temperature of the reaction system is controlled at 15-40°C, and the polymerization reaction is carried out for 5-30 hours to obtain polyamic acid;

[0038] Step 2. Add acetic anhydride and pyridine to the polyamic acid obtained in step 1. The molar ratio of pyromellitic dianhydride, acetic anhydride and pyridine is 1:10:10. Stir while raising the temperature. Raise the temperature to 60-85°C at a rate of 1 min, and carry out imidization reaction. After 12-24 hours of reaction, the reaction is completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com