Dynamic polymer containing composite dynamic covalent bonds and application thereof

A dynamic covalent bond and polymer technology, applied in the field of dynamic polymer materials and polymer materials, can solve problems such as difficult comprehensive performance and limited dynamic performance of dynamic covalent bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

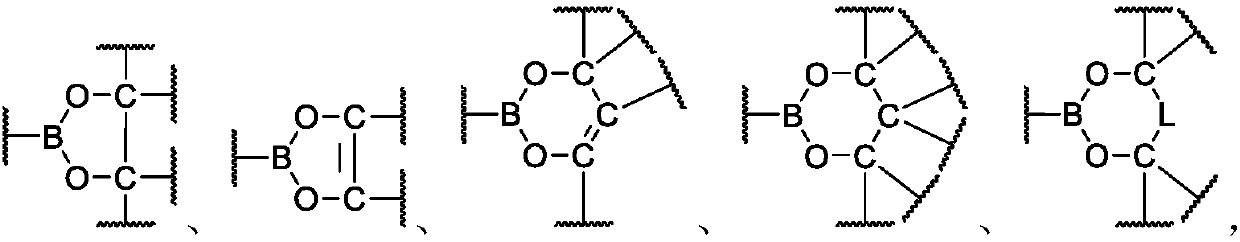

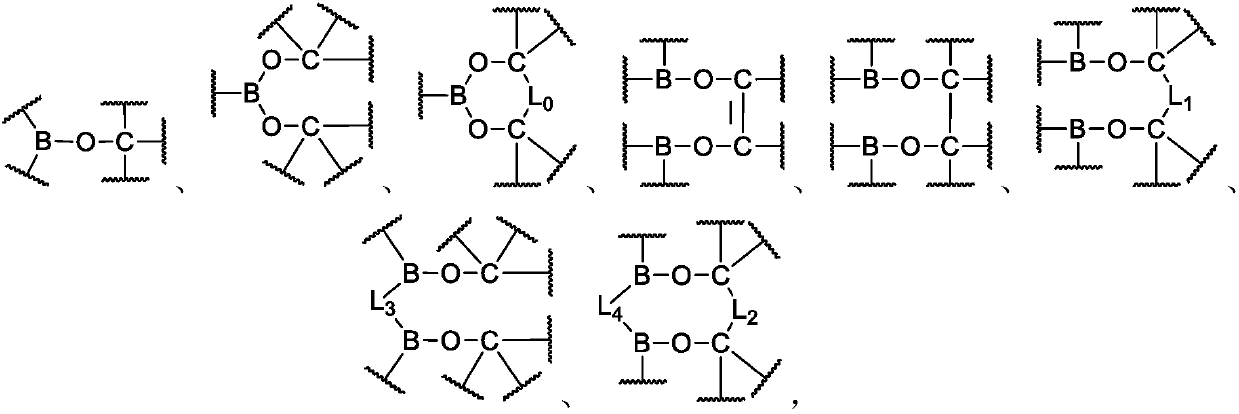

[0432] The present invention provides a method for preparing a dynamic polymer based on combined dynamic covalent bonds. The dynamic polymer has a linear or cyclic structure, which is preferably prepared by at least one of the following methods (but this Invention is not limited to this):

[0433] The first one is obtained by at least the following components participating in the reaction to generate a dynamic covalent bond: at least one organoboron compound (I), at least two hydroxyl-containing compounds (selected from compound I and / or compound II containing organoboron acid groups) And / or compound III and / or compound (IV), the same below); Wherein, organoboron compound (I), hydroxyl-containing compound all contain at most two functional groups;

[0434] The second type is obtained by at least the following components participating in the reaction to generate dynamic covalent bonds and ordinary covalent bonds: at least one organoboron compound (I), at least two hydroxyl-cont...

Embodiment 1

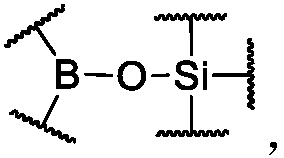

[0537]In No. 1 reactor, add 34g acrylamide-phenylboronic acid-urethane copolymer (using methyl isocyanate, N-(2-hydroxyethyl) acrylamide as raw material reaction to prepare urethane monomer ; Then use AIBN as an initiator to obtain acrylamide, 3-acrylamidophenylboronic acid, and carbamate monomers through free radical polymerization), 300mL deionized water / THF mixed solvent, heat to 50°C for stirring and dissolving , slowly add 3.5g 1,1,3,3,5,5,7,7-octamethyl-1,7-tetrasiloxanediol and 20mL0.3mol / L polyglycerin methanol solution, and add 2g graphene , after ultrasonic dispersion for 40 min, 2.5 mL of triethylamine was added, and the stirring reaction was continued at 50° C. for 2 h. Then add 1.2g sodium dodecylbenzenesulfonate, 0.7g bentonite, 0.5g stearic acid, 0.4g oleic acid, then add 0.4g organic bentonite, 0.3g polydimethylsiloxane, 0.2g Dibutyltin dilaurate and 41 mg of light stabilizer 770 were mixed evenly with heating and stirring to obtain a gray-black liquid with a ...

Embodiment 2

[0539] Add 18.9 mL of polyol compound (using 4-hydroxystyrene and formaldehyde as raw materials, reflux it with zinc nitrate hexahydrate for 24 hours to synthesize 2-(hydroxymethyl)-4-vinylphenol, then Using methanol as a solvent and triethylamine as a catalyst, it is prepared by thiol-alkene click addition reaction with pentaerythritol tetramercaptoacetate), 34mL of 0.2mol / L toluene solution of methylphenyl silicone oil, 1g of 200 The target nanoclay and 0.2mg BHT antioxidant were ultrasonically dispersed for 30min, and then heated to 150°C under stirring; then 3.11g of organoboron compound (propenylboronic acid and 4,6-trithiol is prepared by thiol-ene click reaction), 0.7mL triethylamine, continue to react at 150°C for 40-60min, and then continue to react for 1h under nitrogen protection, then pour it into a suitable mold , and placed the sample in a vacuum oven at 80°C for 24h for further reaction, and then cooled to room temperature for 30min to obtain a block of hard pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com