Preparation method of functionalized polymer microspheres

A technology of polymer microspheres and functionalization, applied in the field of functional polymers, can solve the problems of cumbersome process, complicated process, solvent pollution, etc., and achieve the effect of energy saving in the preparation process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

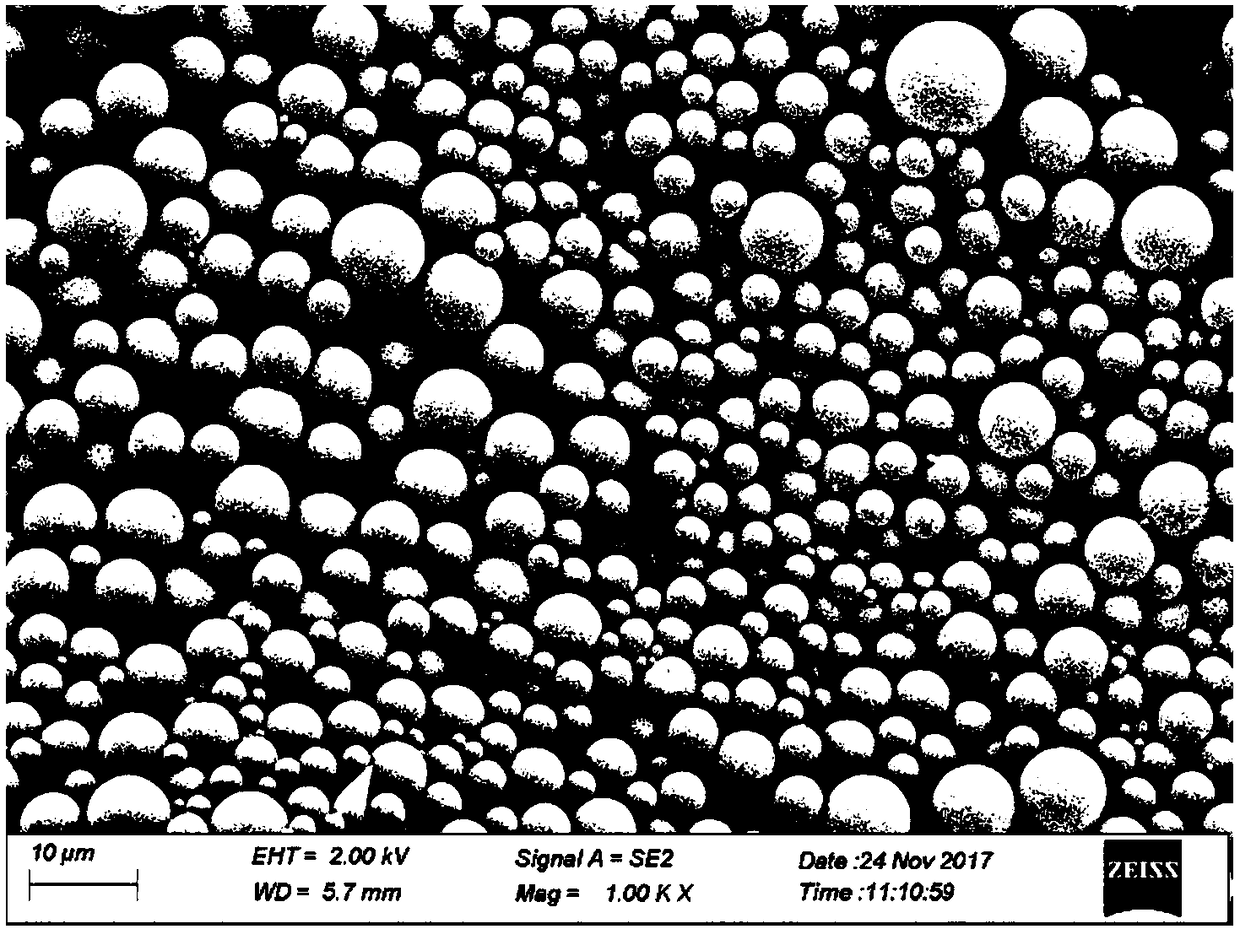

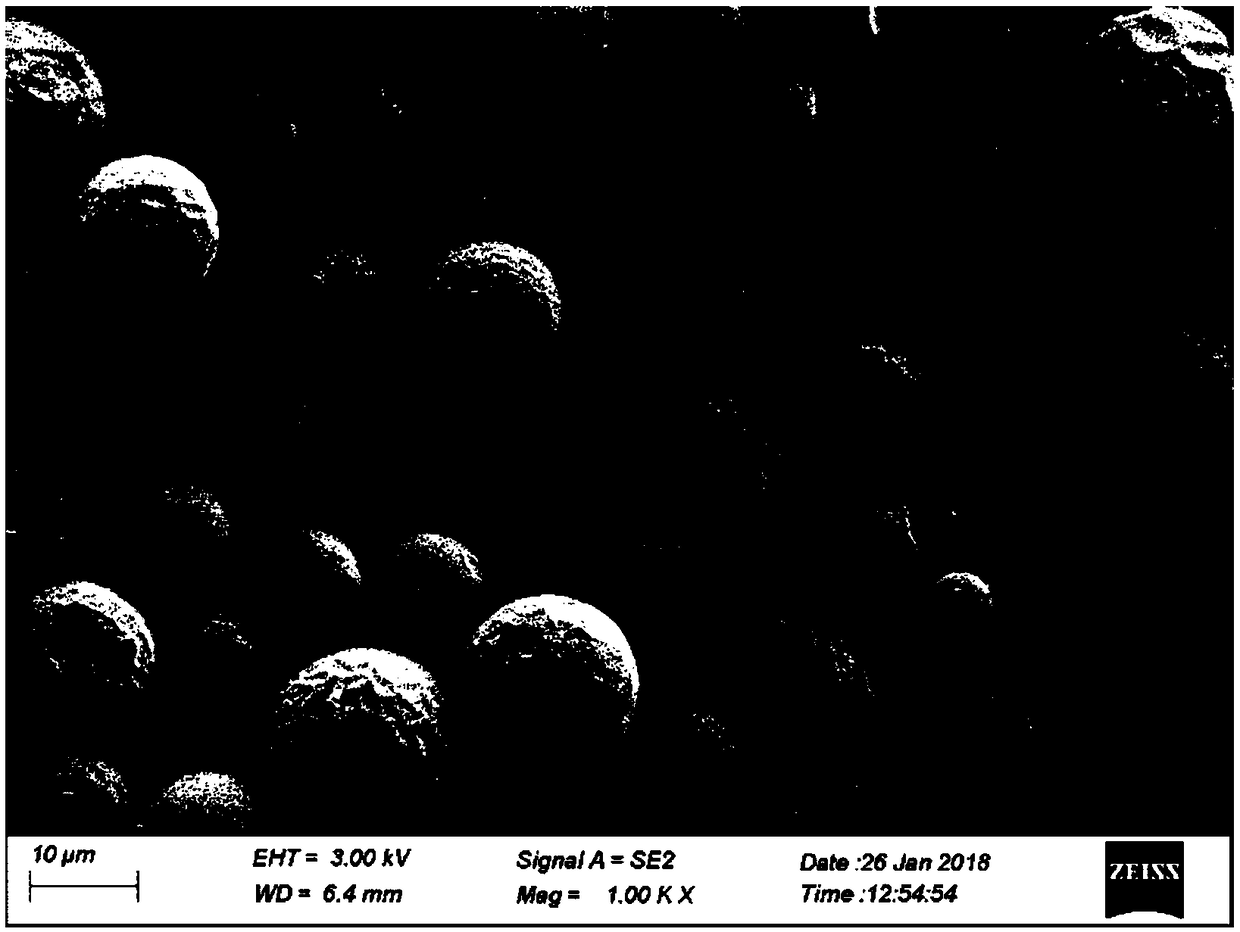

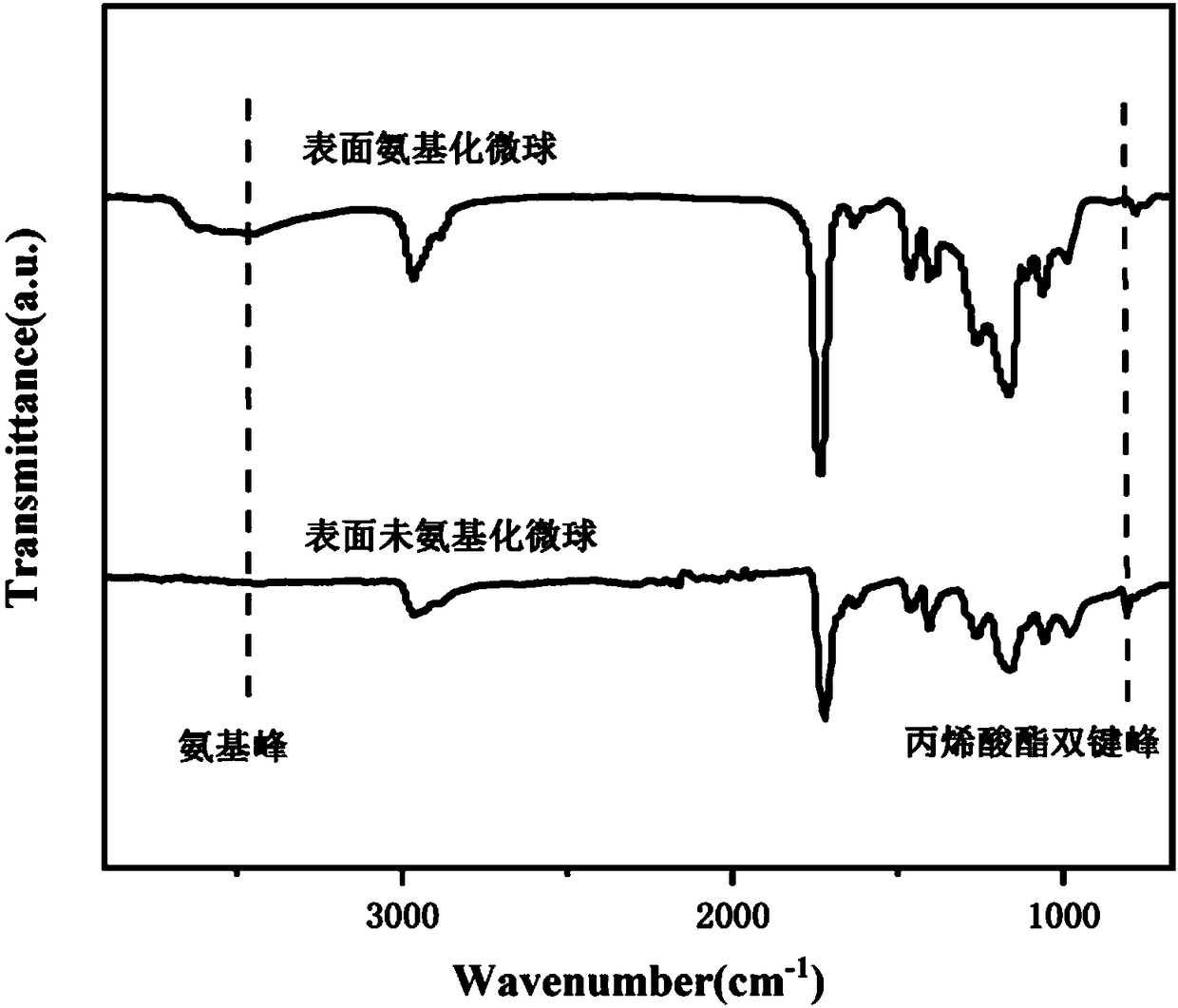

[0020] Dissolve 0.08 g of the initiator 2,4,6-(trimethylbenzoyl)diphenylphosphine oxide in 8 g of trimethylolpropane triacrylate, and place it in a glass reaction vessel filled with 120 mL of deionized water Among them, use a disperser to emulsify the mixed solution for 20 minutes (set the speed at 2500rpm, and maintain it until the end of the light), add 20mL of an aqueous solution of branched polyethyleneimine (concentration is 0.05kg / L); cm 2 Under the irradiation reaction for 40 minutes, the obtained product was washed, centrifuged and dried to obtain polymer microspheres with a particle size of 2-8 μm and a yield of 82%. The particle size and morphology are shown in figure 1 SEM photographs. Take 2 g of the obtained polymer microspheres and place them in a glass reaction vessel containing 20 mL of branched polyethyleneimine aqueous solution (concentration: 0.1 kg / L), pass nitrogen into the system for 10 min, seal it, and heat it at 80 ° C for 10 h. The obtained polymer ...

Embodiment 2

[0022] Dissolve 0.1 g of the initiator 2,4,6-trimethylbenzoyl ethyl phosphonate in 6 g of trimethylolpropane trimethacrylate, and place it in a glass reaction vessel filled with 100 mL of deionized water. The disperser was emulsified for 15min (the speed was set at 2500rpm and maintained until the end of the light), and 10mL of the aqueous solution of branched polyethyleneimine was added (the concentration was 0.05kg / L); 2 Under the irradiation reaction for 60 minutes, the obtained product is washed, centrifuged and dried to obtain polymer microspheres with a particle size of 8-15 μm and a yield of 78%. Place 1 g of the obtained polymer microspheres in a glass reaction vessel containing 20 mL of branched polyethyleneimine aqueous solution, pass nitrogen gas into the system for 8 minutes, seal it, heat at 60°C for 8 hours, and take 1 g of the obtained polymer microspheres to centrifuge Washing several times, drying to obtain the target product.

Embodiment 3

[0024] Dissolve 0.5 g of the initiator bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide in 10 g of 1,6-hexanediol diacrylate, and place in a glass reaction vessel filled with 50 mL of deionized water Among them, the disperser was emulsified for 15 minutes (the speed was set at 2300rpm and maintained until the end of the light), and 25mL of an aqueous solution of branched polyethyleneimine was added (the concentration was 0.05kg / L); 2 Under irradiation for 90 minutes, the obtained product is washed, centrifuged and dried to obtain polymer microspheres with a particle size of 40-80 μm and a yield of 76%. Take 0.8g of the obtained polymer microspheres and place them in a glass reaction vessel with 20mL of branched polyethyleneimine aqueous solution (concentration: 0.1kg / L), pass nitrogen into the system for 5 minutes, seal it, and heat it at 100°C for 1 hour. The obtained polymer microspheres were centrifuged and washed several times, and dried to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com