Method for preparing micro fluidic chip template

A technology of microfluidic chips and templates, applied in the field of microfluidics, can solve the problems of negative impact on graphic accuracy, low repeatability, complicated operation, etc., and achieve the effects of rough surface, low cost, and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

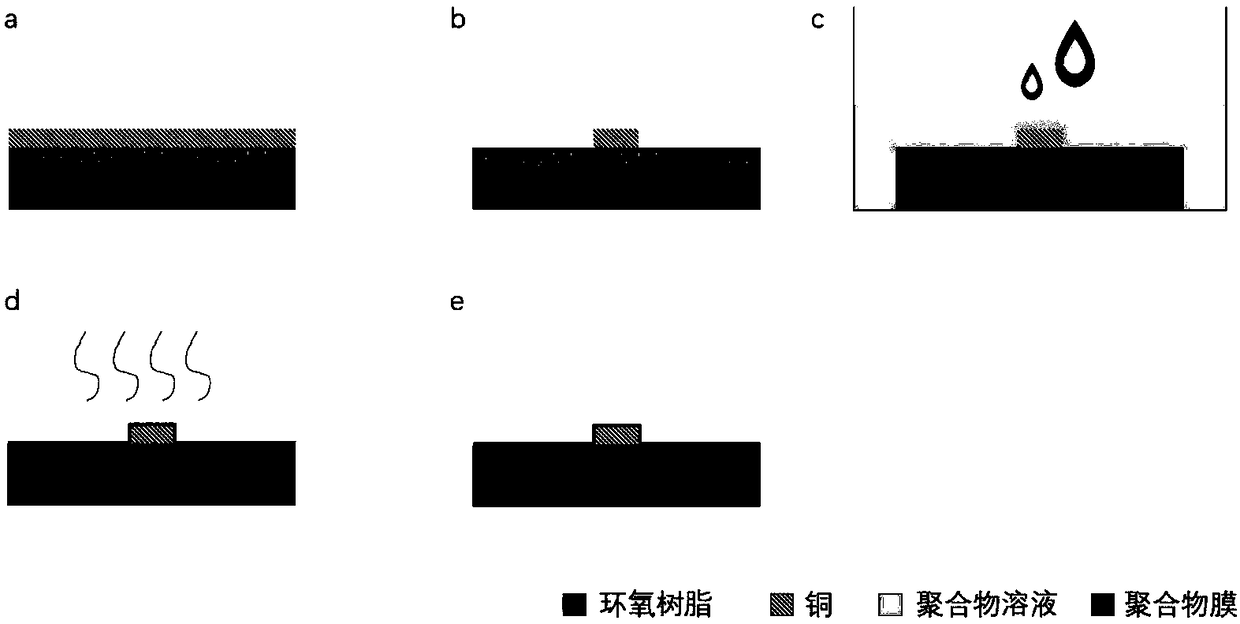

[0025] The invention discloses a preparation method of a microfluidic chip template, such as figure 1 shown, including the following steps:

[0026] S1: Making a patterned template with a rough surface using a standard printed circuit board manufacturing process, that is, using a standard printed circuit board manufacturing process to obtain a template with a rough surface but a patterned copper layer;

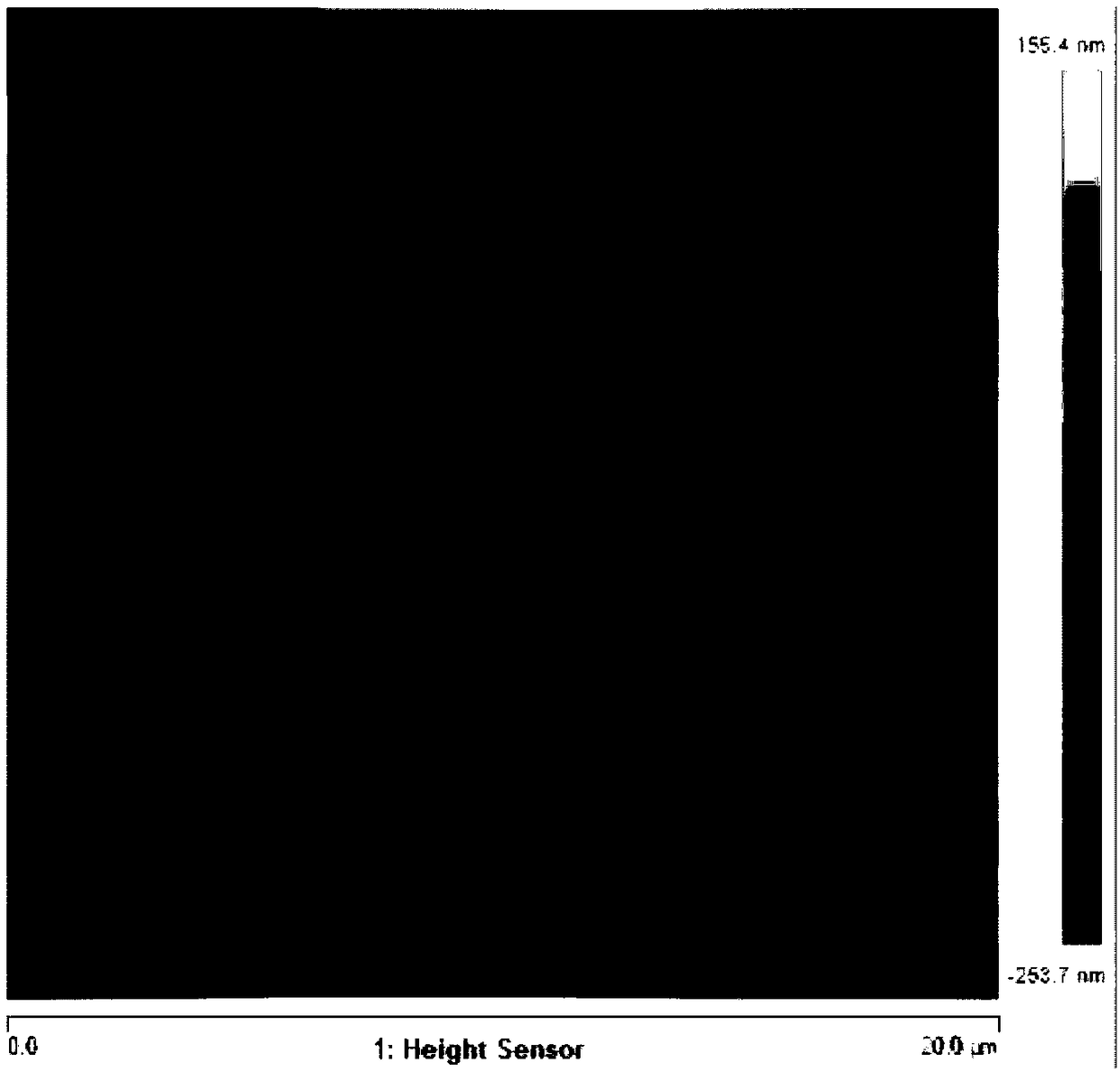

[0027] S2: Use the surface smoothing method based on polymer coating to planarize the rough surface of the exposed epoxy resin: soak the rough template in the polymer solution, and as the solvent volatilizes, the polymer gradually precipitates to form an attached The film on the template is used to planarize the rough surface of the epoxy resin; the solvent used in the polymer solution is a volatile solvent, including one or more of methylene chloride, chloroform, and toluene; the polymer in the polymer solution is poly Carbonate and / or polystyrene;

[0028] S3: Bake the tem...

Embodiment 1

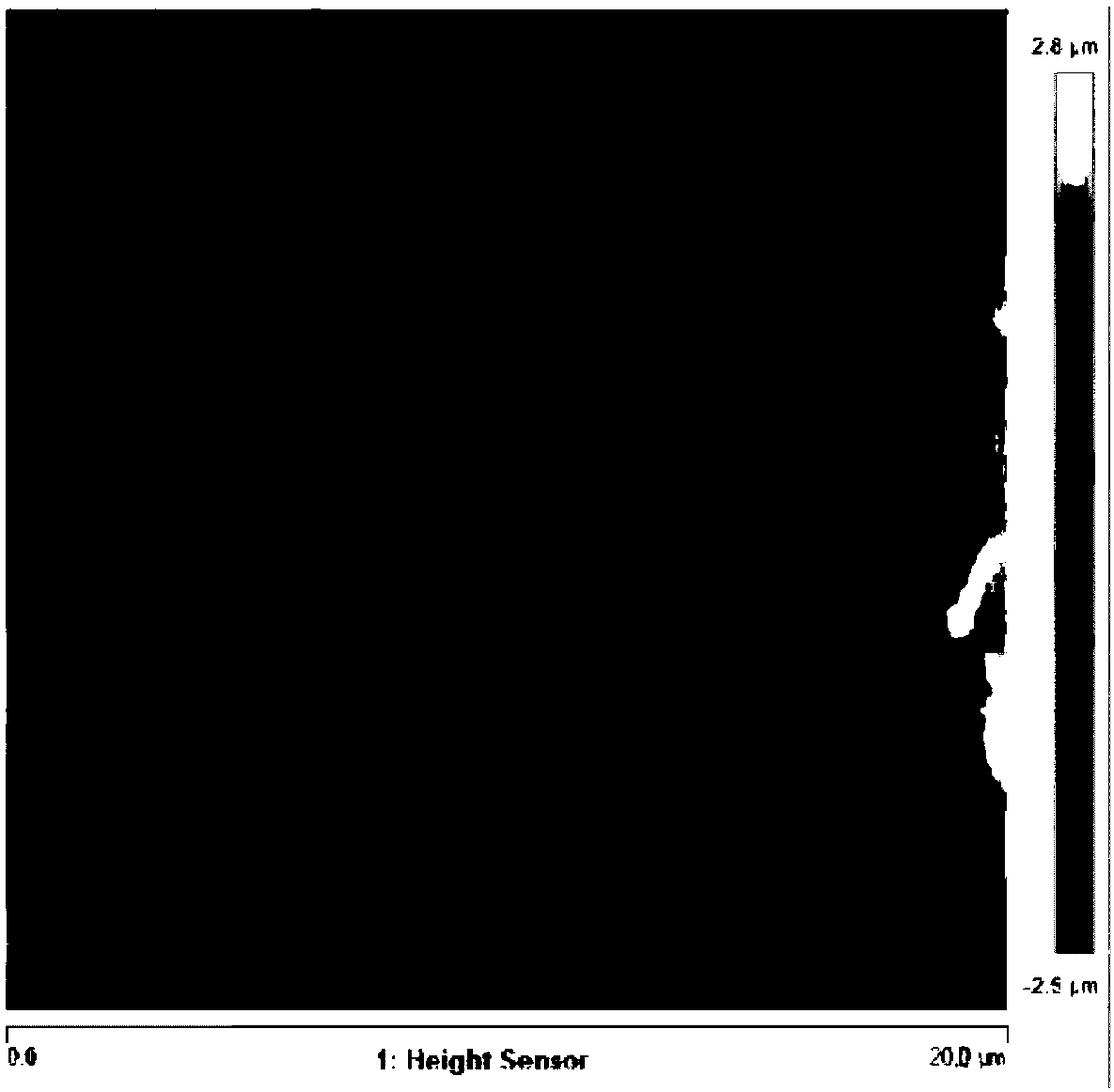

[0030] by figure 2 The design of the microfluidic chip as an example. The dichloromethane solution of polystyrene was selected as the film-forming solution. The solution concentration is 0.2 wt.%. The baking temperature is selected as 90° C. for 1 hour. The method is used to prepare a microfluidic chip template with a height of 70 um and a minimum line width of 100 um.

[0031] Step 1. Fabricate a patterned stencil with a rough surface using a standard PCB fabrication process

[0032] FR4 glass fiber epoxy resin copper clad laminate with 2oz (70um) copper layer thickness is selected as the experimental raw material. After standard cleaning, lamination, exposure, development, copper engraving, and film removal, a printed circuit board conforming to the design drawing is produced.

[0033] Cleaning includes plasma water cleaning, ultrasonic cleaning, air knife drying, etc.

[0034] Lamination means laminating a layer of photosensitive film on the copper clad board and pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com