A kind of manufacturing method of bamboo plywood

A production method and plywood technology, applied in the field of board manufacturing, can solve the problems of low bonding strength of natural adhesives, non-natural adhesives containing formaldehyde, and poor water resistance, so as to achieve weak adhesion, prevent bamboo cracking, and prevent bamboo from cracking. good cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

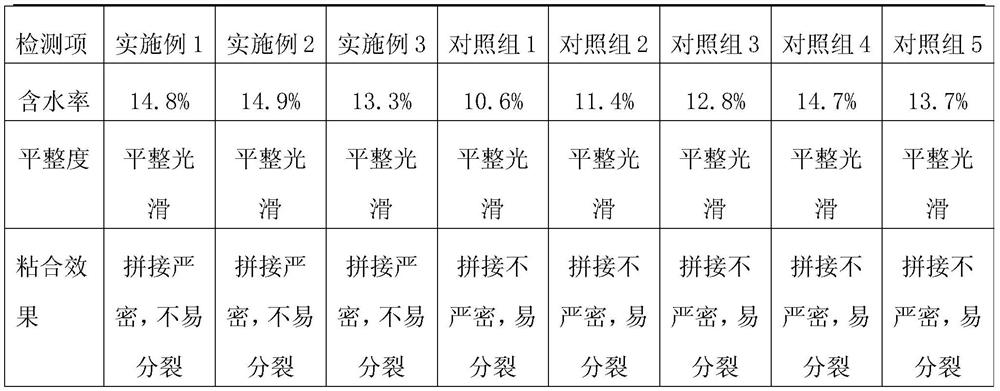

Examples

Embodiment 1

[0028] A kind of manufacture method of bamboo plywood comprises the steps:

[0029] (1) heat treatment: the bamboo is placed in the lye and boiled for 30min; the lye is a sodium hydroxide solution with a molar concentration of 1mol / L;

[0030] (2) coating anti-cracking agent: after the bamboo after the poaching is taken out from lye, smear on the surface of bamboo with anti-cracking agent immediately; Described anti-cracking agent coating amount is 80g / m ; Described anti-cracking agent is made of The following raw materials are composed of parts by mass: 20 parts of turpentine, 5 parts of camphor, 2 parts of chitosan, 9 parts of cornstarch, 1 part of ethyl acetate, 7 parts of flavonoids, and 1 part of phenol;

[0031] (3) making bamboo chips;

[0032] (4) Drying: the bamboo chips are placed in a drier with a relative air humidity of 30%, and the temperature is 30°C, and the wind speed is 20m / s to dry to a moisture content of 15% of the bamboo chips;

[0033] (5) Repair;

[...

Embodiment 2

[0041] A kind of manufacture method of bamboo plywood comprises the steps:

[0042] (1) heat treatment: the bamboo is placed in the lye and boiled for 20min; the lye is potassium hydroxide with a molar concentration of 1mol / L;

[0043] (2) be coated with anti-cracking agent: after the bamboo after the poaching is taken out from lye, be applied to the surface of bamboo with anti-cracking agent immediately; Described anti-cracking agent coating amount is 50g / m ; Described anti-cracking agent is made of The following raw materials are composed of parts by mass: 30 parts of turpentine, 1 part of camphor, 7 parts of chitosan, 2 parts of cornstarch, 5 parts of ethyl acetate, 4 parts of flavonoids, and 7 parts of phenol;

[0044] (3) making bamboo chips;

[0045] (4) Drying: the bamboo chips are placed in a drier with a relative air humidity of 26%, and the temperature is 40° C., and the wind speed is 10 m / s to dry to the moisture percentage of the bamboo chips to be 20%;

[0046] ...

Embodiment 3

[0054] A kind of manufacture method of bamboo plywood comprises the steps:

[0055] (1) heat treatment: the bamboo is placed in the lye and boiled for 25min; the lye is a calcium hydroxide solution with a molar concentration of 2mol / L;

[0056] (2) be coated with anti-cracking agent: after the bamboo after the poaching is taken out from lye, be applied to the surface of bamboo with anti-cracking agent immediately; Described anti-cracking agent coating amount is 60g / m ; Described anti-cracking agent is made of The following raw materials are composed of parts by mass: 25 parts of turpentine, 3 parts of camphor, 5 parts of chitosan, 6 parts of cornstarch, 3 parts of ethyl acetate, 5 parts of flavonoids, and 6 parts of phenol;

[0057] (3) making bamboo chips;

[0058] (4) Drying: the bamboo chips are placed in a drier with a relative air humidity of 28%, with a temperature of 35°C and a wind speed of 15m / s to dry the bamboo chips to a moisture content of 18%;

[0059] (5) Repa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com