Preparation method of ceramic target material for thermal barrier coating with high uniformity and short flow electron beam physical vapor deposition

A physical vapor deposition and thermal barrier coating technology, which is applied in the field of preparing ceramic targets for electron beam physical vapor deposition thermal barrier coatings, can solve the problems of reduced thermal shock resistance of ceramic targets and reduced stability of deposition process, etc. Achieving good thermal stress release capability, good sphericity and fluidity, and moderate density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] first step:

[0077] Using chemically synthesized yttria partially stabilized zirconia (6-8YSZ) raw material, the raw material purity is 99.93%, the remaining impurity content is 0.07wt%, the average grain size of the raw material is 0.05μm, and the raw material state is the slurry spray-dried material after synthesis.

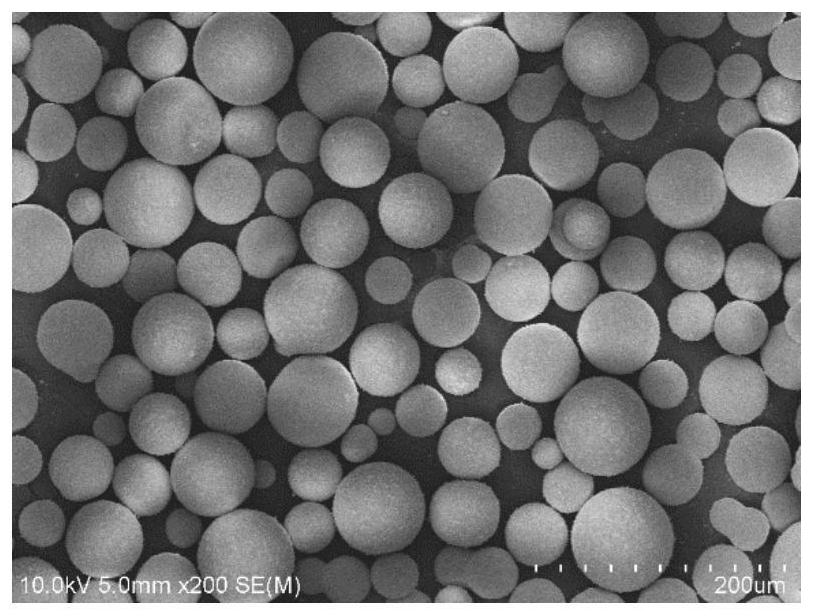

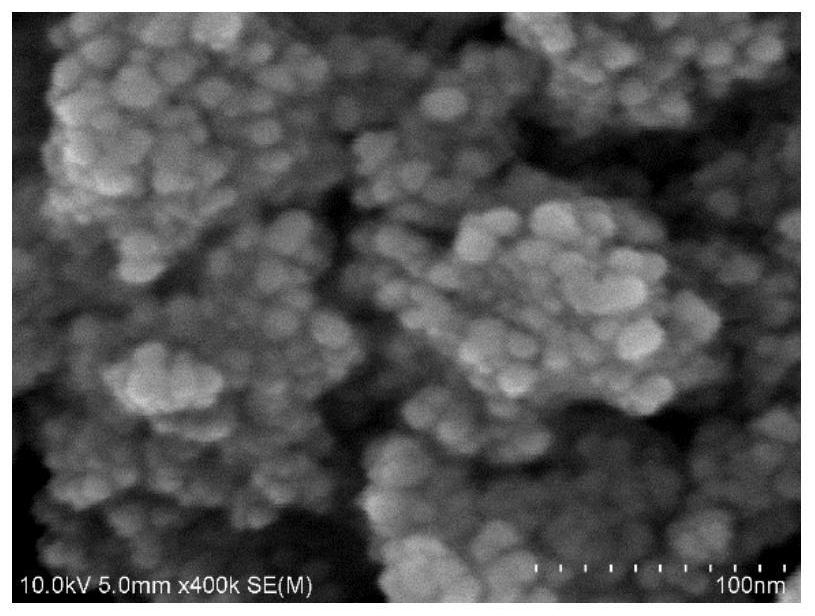

[0078]Weigh a certain amount of raw material powder, according to the solid content of 40%, add pure water to the raw material to prepare a slurry, and perform ball milling. Add 0.1% polyvinyl alcohol during the ball milling process. After the ball milling, use a laser particle size analyzer to test the slurry Material D 50 It is 0.15 μm, and the viscosity of the slurry after ball milling is 90 mPa·S using a viscometer. Use high-speed centrifugal spray drying equipment to agglomerate and granulate the slurry. After granulation, the powder is dried at 100°C for 5 hours, and the dried powder is sieved to 10-120 μm to obtain powder A and the cross-section...

Embodiment 2

[0091] first step:

[0092] The chemically synthesized yttria partially stabilized zirconia (6-8YSZ) raw material is used, the raw material purity is 99.92%, the remaining impurity content is 0.08wt%, the average grain size of the raw material is 0.05 μm, and the raw material state is a slurry spray-dried material after synthesis.

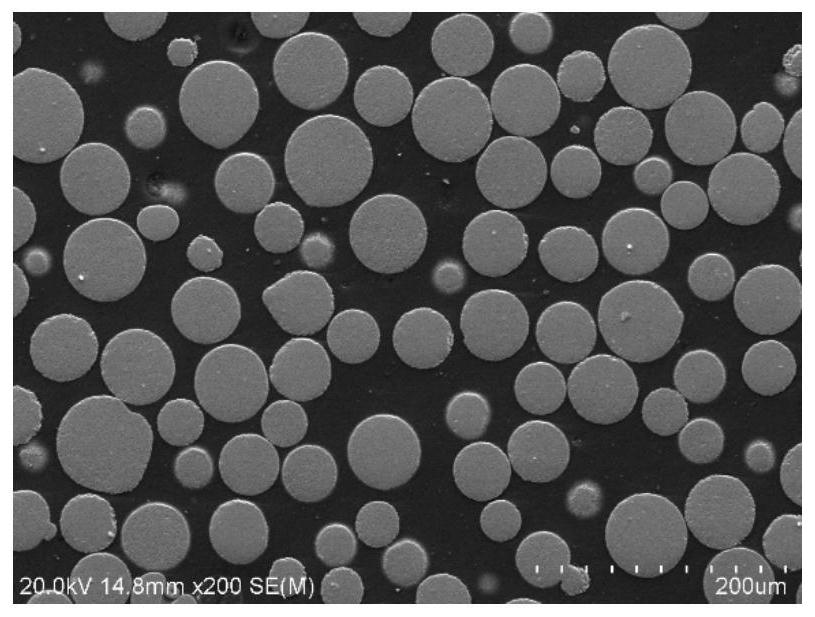

[0093] Weigh a certain amount of raw material powder, according to the solid content of 50%, add pure water to the raw material to prepare a slurry, and perform ball milling. Add 0.5% polyvinyl alcohol during the ball milling process. After the ball milling, use a laser particle size analyzer to test the slurry Material D 50 It is 0.12 μm, and the viscosity of the slurry after ball milling is 85 mPa·S using a viscometer. Use high-speed centrifugal spray drying equipment to spray dry the slurry. After granulation, the powder is dried at 100°C for 5 hours, and the dried powder is sieved to 10-120 μm to obtain powder A. The bulk density of powder A i...

Embodiment 3

[0104] first step:

[0105] The chemically synthesized gadolinium zirconate (GZO) raw material is used, the raw material purity is 99.91%, the remaining impurity content is 0.09wt%, the average grain size of the raw material is 0.05 μm, and the raw material state is a slurry spray-dried material after synthesis.

[0106] Weigh a certain amount of raw material powder, according to the solid content of 47%, add pure water to the raw material to prepare a slurry, and perform ball milling. During the ball milling process, add 0.4% polyvinyl alcohol. After the ball milling, use a laser particle size analyzer to test the slurry Material D 50 It is 0.12 μm, and the viscosity of the slurry after ball milling is 85 mPa·S using a viscometer. Use high-speed centrifugal spray drying equipment to spray dry the slurry. After granulation, the powder is dried at 100°C for 4 hours, and the dried powder is sieved to 10-120 μm to obtain powder A. The bulk density of powder A is 1.05 g / cm 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com