High-performance small-particle-size ternary positive electrode material precursor and preparation method thereof

A positive electrode material and small particle size technology, which is applied in the field of high-performance small particle size ternary positive electrode material precursor and its preparation, can solve the problems of difficult mixing, poor electrochemical performance, and slow solid phase diffusion speed. Achieve good sphericity, ensure purity and integrity, improve safety performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

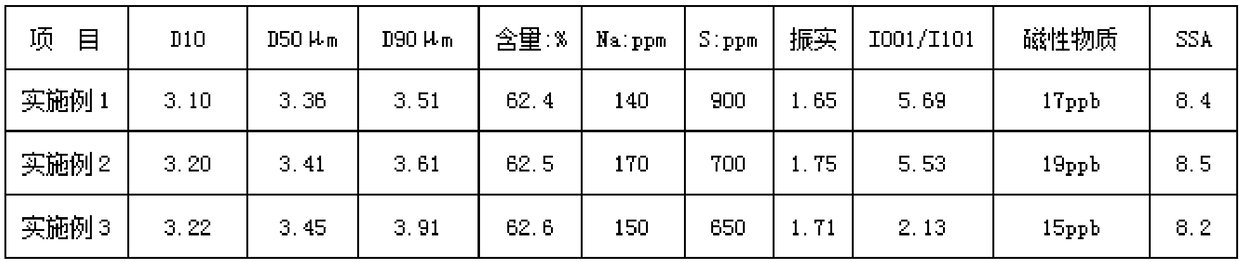

[0027] Prepare 3μmNi 0.25 co0.30 mn 0.30 Ca 0.05 (OH) 2 Ternary cathode material precursor.

[0028] (1) Nickel sulfate, cobalt sulfate, manganese sulfate, calcium sulfate, sodium hydroxide, and ammonia water are used as reaction raw materials to prepare 1.8mol / L nickel-cobalt-manganese metal salt solution at 30~35°C (the ratio of nickel-cobalt-manganese-calcium is 0.25:0.30:0.30:0.05), 6mol / L sodium hydroxide solution, 10mol / L ammonia water, after passing the feed liquid through precision filtration and demagnetization device respectively, put it into the feed liquid tank for standby.

[0029] (2) Add 800L of pure water to the 2000L reactor to submerge the reaction paddles, and feed N 2 Protection, flow rate 20L / min, stirring speed 100r / min and stirring for 30min, add sodium hydroxide solution to the bottom liquid, adjust pH to 12.0, continue stirring for 60min, control stirring speed 500r / min, and add ammonia water 20L into the kettle. After the ammonia water is added, ...

Embodiment 2

[0031] Prepare 3μmNi 0.37 co 0.30 mn 0.30 Mg 0.03 (OH) 2 Ternary cathode material precursor.

[0032] (1) Nickel chloride, cobalt chloride, manganese chloride, magnesium chloride, sodium hydroxide, and ammonia water are used as reaction raw materials, and 1.5mol / L nickel-cobalt-manganese metal salt solution (nickel-cobalt-manganese The calcium ratio is 0.37:0.30:0.30:0.03), 4mol / L sodium hydroxide solution, and 8mol / L ammonia water. After the feed liquid is passed through a precision filter and a demagnetization device, it is poured into the feed liquid tank for standby.

[0033] (2) Add 800L of pure water to the 2000L reactor to submerge the reaction paddles, and feed N 2 Protection, flow rate 20L / min, stirring speed 100r / min, stir for 30min, add sodium hydroxide solution to the bottom liquid, adjust the pH to 12.2, continue stirring for 60min, control the speed to 500r / min, and add ammonia water 20L into the kettle. After the ammonia water is added, add the nickel-coba...

Embodiment 3

[0035] Prepare 3μmNi 0.62 co 0.20 mn 0.15 Ca 0.03 (OH) 2 Ternary cathode material precursor.

[0036] (1) Nickel sulfate, cobalt sulfate, manganese sulfate, calcium sulfate, sodium hydroxide, and ammonia water are used as reaction materials to prepare 2mol / L nickel-cobalt-manganese metal salt solution at 35~40°C (the ratio of nickel-cobalt-manganese-calcium is 0.62 :0.20:0.15:0.03), 6mol / L sodium hydroxide solution, 8mol / L ammonia water, after passing the feed liquid through precision filtration and demagnetization device respectively, pour it into the feed liquid tank for standby.

[0037] (2) Add 600L of pure water to the 2000L reactor to submerge the reaction paddles, and pass in N 2 Protection, flow rate 20L / min, stirring speed 100r / min, stirring for 30min, adding sodium hydroxide solution to the bottom liquid, adjusting the pH to 12.0~12.1, continuing to stir for 60min, increasing the stirring speed to 300r / min, and adding Ammonia water 28L. After adding the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com