Composite magnetic nanoparticles Fe3O4@Au/MPA/NTA-Ni<2+> as well as preparation and application thereof

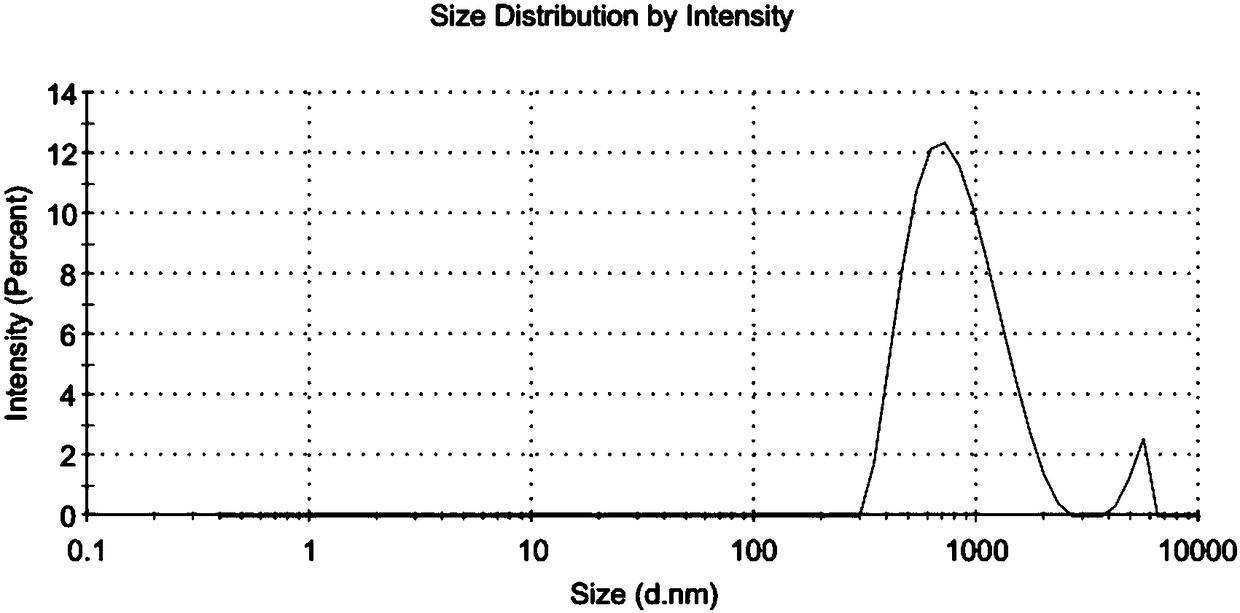

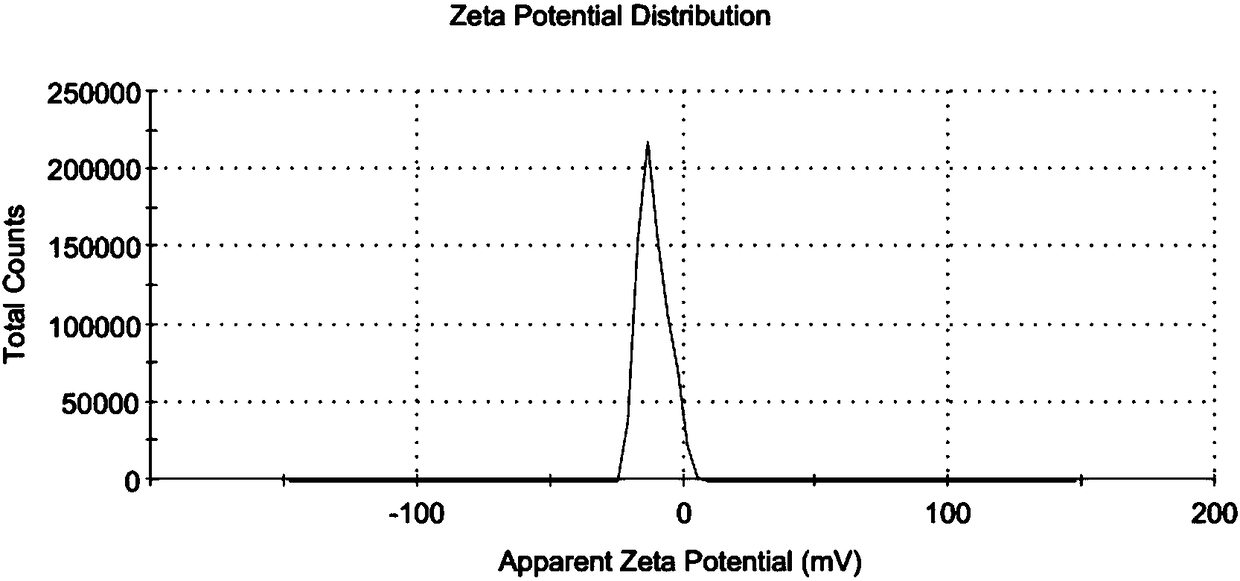

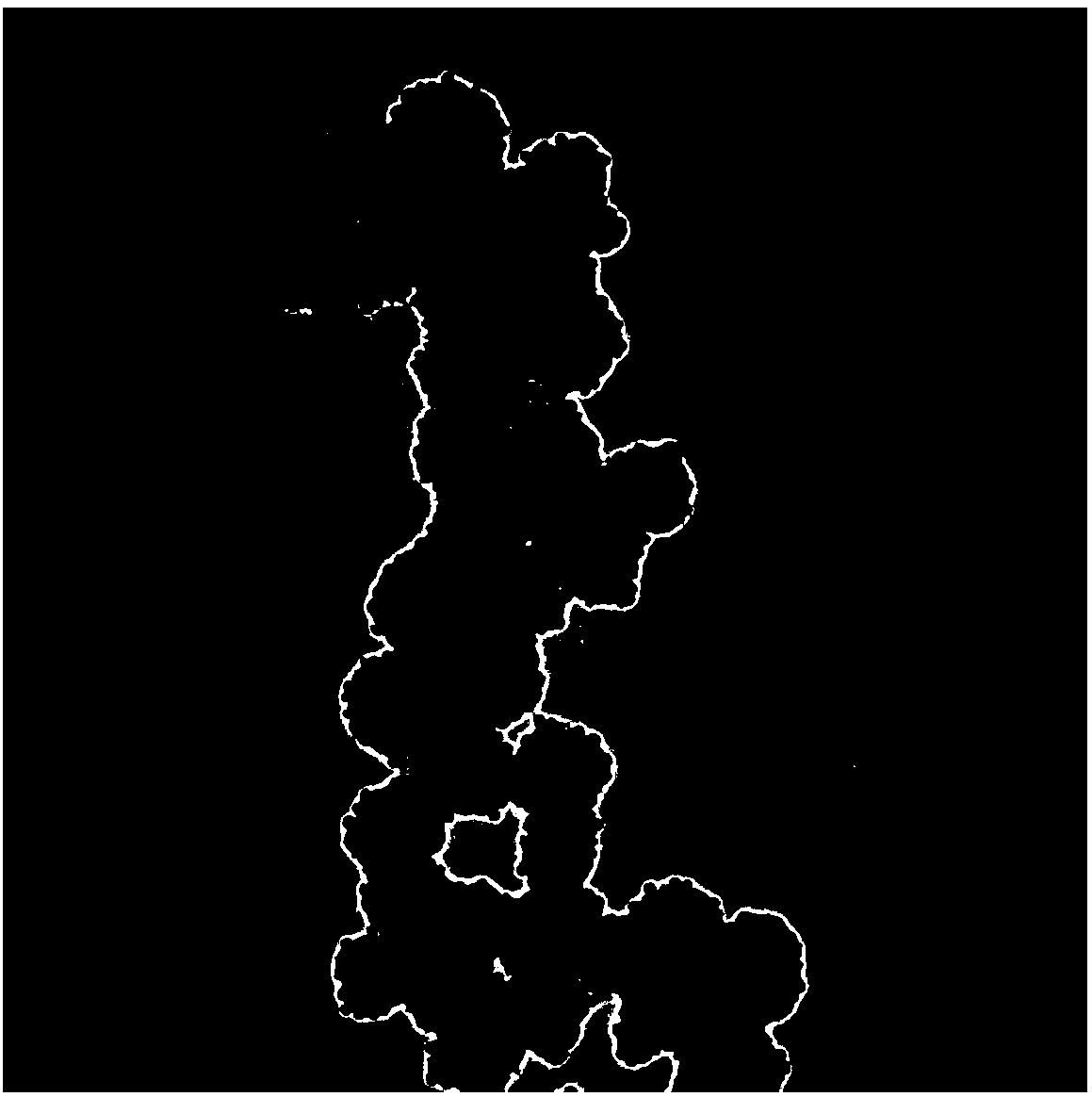

A nano-particle and composite magnetic technology, which is applied in the field of nano-magnetic materials and biology, can solve the problems of stability and uneven surface modification, and achieve good monodispersity, good dispersion, and rapid separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The above-mentioned composite magnetic nanoparticles Fe 3 o 4 @Au / MPA / NTA-Ni 2+ Prepared by the following method, comprising the steps of:

[0041] 1) Preparation of Fe by solvothermal method 3 o 4 Nanoparticles: 1.156g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 3.3012g ammonium acetate (NH 4 AC), 0.3424g of trisodium citrate dissolved in 60mL of ethylene glycol, heated to 170 ° C for 1 hour; after cooling to room temperature, the solution was transferred to the reaction kettle, and reacted at 200 ° C for 16 hours; after the reaction, magnetic Separation, washing with absolute ethanol and water alternately for 3 times, and finally dispersing in absolute ethanol;

[0042] 2) Fe 3 o 4 Surface modification of nanoparticles: ①Take 1.96g of maleic anhydride (maleic anhydride) in a 10mL round bottom flask, add 3.4mL of aminopropyltriethoxysilane (APTES) dropwise under ice-water bath conditions , put into the rotor and stir until the reactant turns into a white so...

Embodiment 2

[0049] The above-mentioned composite magnetic nanoparticles Fe 3 o 4 @Au / MPA / NTA-Ni 2+ Prepared by the following method, comprising the steps of:

[0050] 1) Preparation of Fe by solvothermal method 3 o 4 Nanoparticles: 1.156g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 2.312g ammonium acetate (NH 4 AC), 0.8216g of trisodium citrate dissolved in 60mL of ethylene glycol, heated to 170 ° C for 1 h; after cooling to room temperature, the solution was transferred to the reaction kettle, and reacted at 200 ° C for 8 h; after the reaction, magnetic separation was carried out. Alternately wash 3 times with absolute ethanol and water, and finally disperse in absolute ethanol;

[0051] 2) Fe 3 o 4 Surface modification of nanoparticles: ①Take 1.96g of maleic anhydride (maleic anhydride) in a 10mL round bottom flask, add 3.4mL of aminopropyltriethoxysilane (APTES) dropwise under ice-water bath conditions , put into the rotor and stir until the reactant turns into a white soli...

Embodiment 3

[0057] The above-mentioned composite magnetic nanoparticles Fe 3 o 4 @Au / MPA / NTA-Ni 2+ Prepared by the following method, comprising the steps of:

[0058] 1) Preparation of Fe by solvothermal method 3 o 4 Nanoparticles: 1.156g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 5.78g ammonium acetate (NH 4 AC), 0.2312g of trisodium citrate dissolved in 60mL of ethylene glycol, heated to 170 ° C for 1 h; after cooling to room temperature, the solution was transferred to the reaction kettle, and reacted at 200 ° C for 10 h; after the reaction, magnetic separation was carried out. Alternately wash 4 times with absolute ethanol and water, and finally disperse in absolute ethanol;

[0059] 2) Fe 3 o 4 Surface modification of nanoparticles: ①Take 1.96g of maleic anhydride (maleic anhydride) in a 10mL round bottom flask, add 3.4mL of aminopropyltriethoxysilane (APTES) dropwise under ice-water bath conditions , put into the rotor and stir until the reactant turns into a white soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com