Preparation method and application of alkynyl carbon material

A technology of carbon materials and monoacetylene, applied in the direction of nano-carbon, electrical components, battery electrodes, etc., can solve the problems of limited promotion and inability to realize industrialization, and achieve the effect of simplifying equipment and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

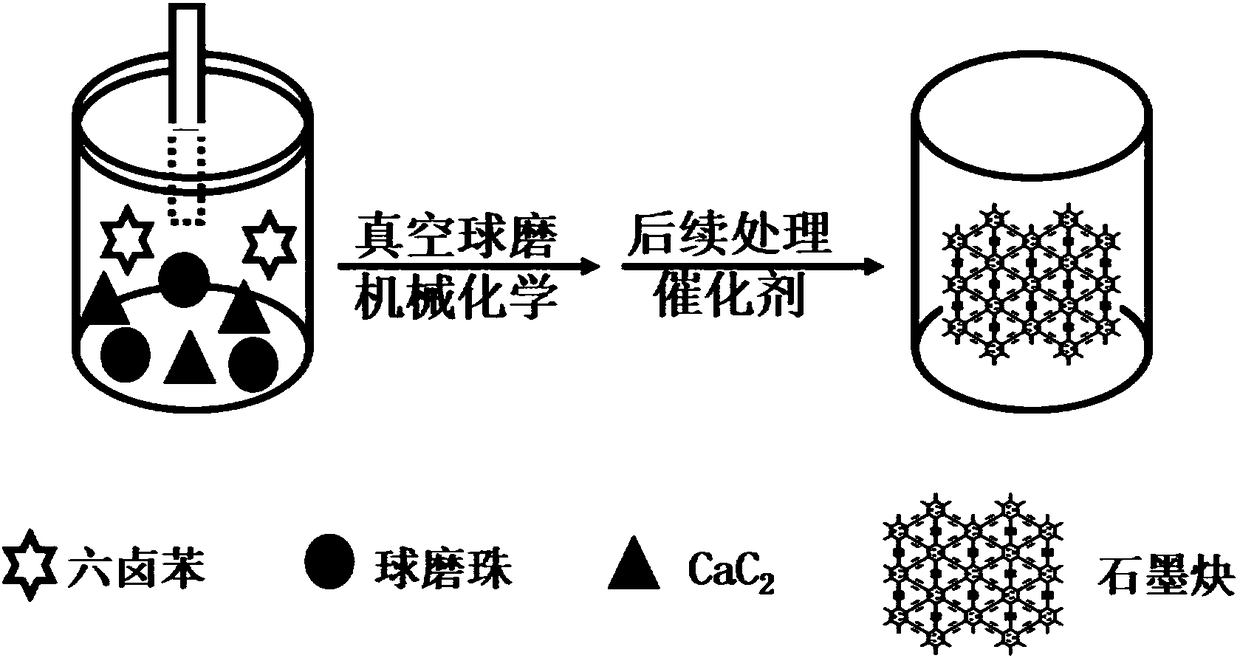

Method used

Image

Examples

Embodiment 1

[0039] With the pellet mass ratio of 1:20, take by weighing hexachlorobenzene (C 6 Cl 6 ) and calcium carbide (CaC 2 ), put it in a ball mill jar, and add absolute ethanol until the grinding material is submerged. Seal the ball mill jar. Ball milled for 18 hours by a planetary ball mill at a rate of 400 rpm. The milled samples were taken out and washed with deionized water to remove unreacted calcium carbide. After drying, wash with hot benzene to remove unreacted hexahalobenzene, and obtain graphyne powder directly.

[0040] Measure 50 ml of methyl orange solution (10 mg / L), add 50 mg of sample, and after standing for 3 hours, irradiate with ultraviolet-visible light to carry out photocatalytic degradation reaction. Every 20 minutes, measure the absorbance change of the solution using UV-vis absorption spectroscopy.

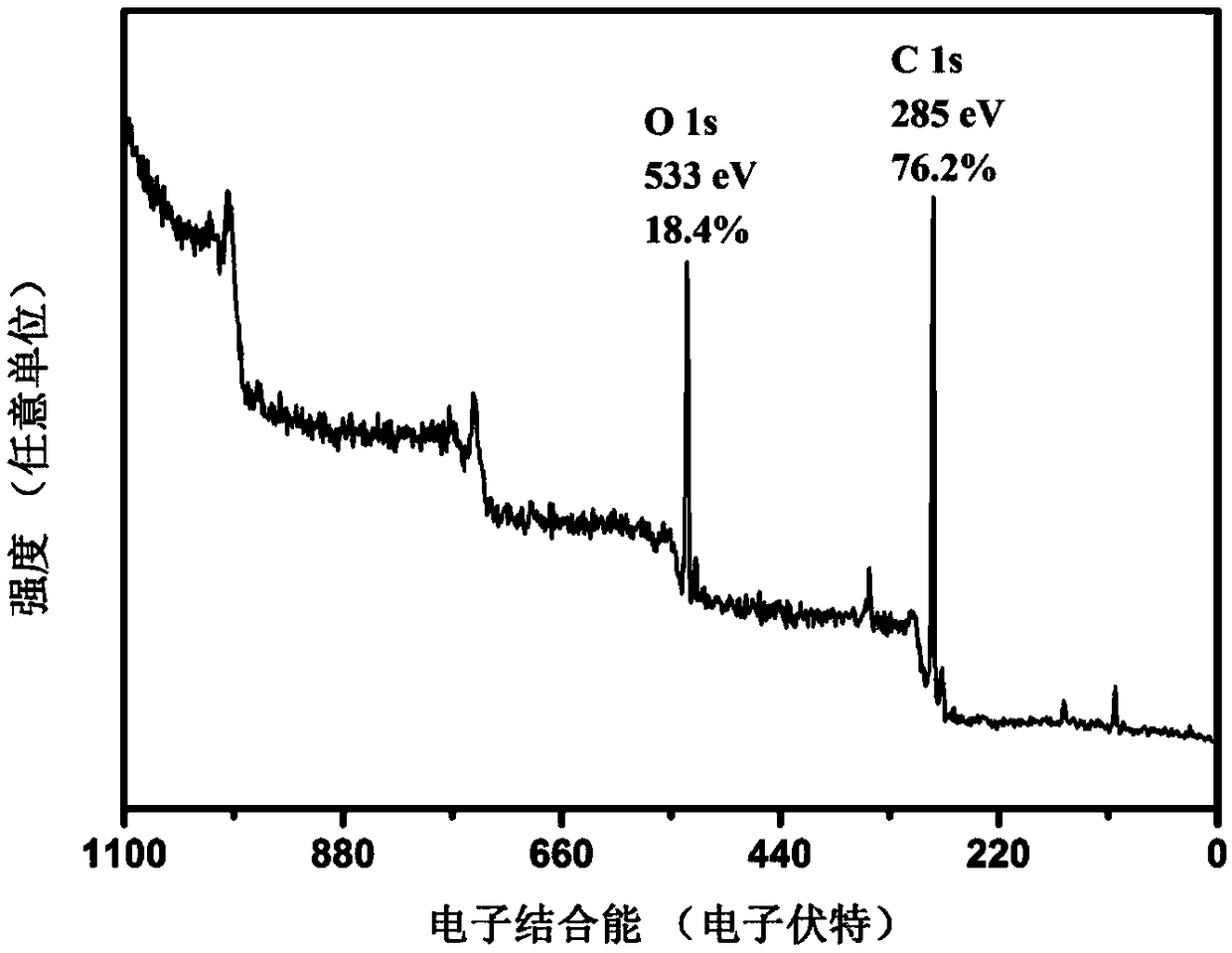

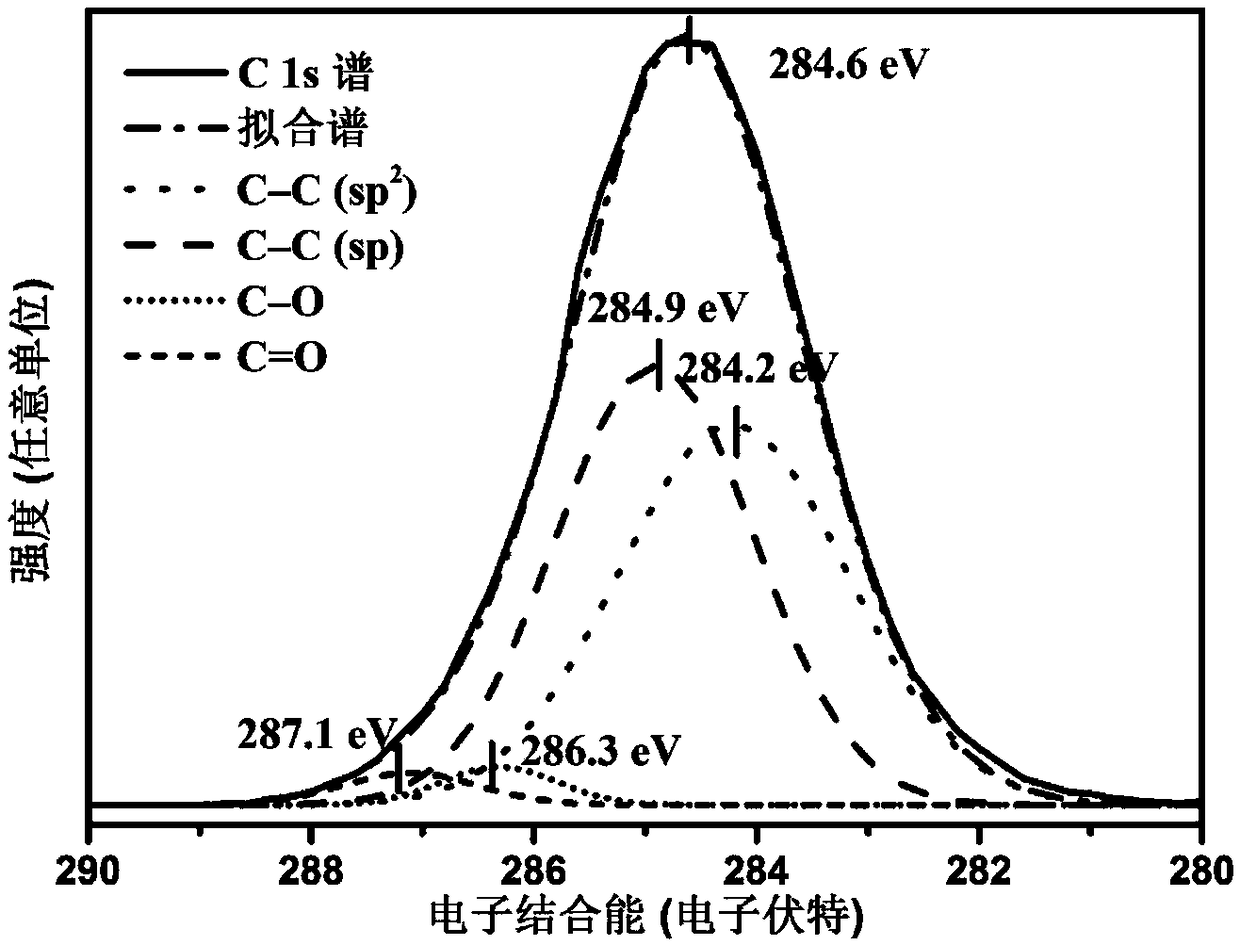

[0041] The full spectrum of X-ray photoelectron spectroscopy of the sample ( figure 2 ) shows that the sample is only composed of carbon elements except...

Embodiment 2

[0043] With the pellet mass ratio of 1:50, take by weighing hexabromobenzene (C 6 Br 6 ) and calcium carbide (CaC 2 ), placed in a vacuum ball mill jar, and added absolute ethanol until the grinding material was submerged. Seal the ball milling jar, and feed nitrogen into the ball milling jar (N 2 ). Ball milled for 12 hours by a planetary ball mill at a rate of 500 rpm.

[0044] After washing and drying the ball-milled sample according to the method described in Example 1, mix the sample with polyethylene glycol, ethyl cellulose, and ethanol according to the mass ratio: 9:9:1:1, and mix the sample at 40~90°C Stir magnetically for 2-10 hours. The obtained slurry is spin-coated on conductive glass, and after drying, it is annealed in a muffle furnace at 260-300°C to remove surfactants such as polyethylene glycol and ethyl cellulose. Use wires, conductive glue, insulating glue, etc. to package the annealed electrode to obtain the working electrode of the sample.

[0045] ...

Embodiment 3

[0047]With the pellet mass ratio of 1:100, take by weighing hexaiodobenzene (C 6 I 6 ) and calcium carbide (CaC 2 ), placed in a vacuum ball mill jar, adding absolute ethanol to fill the ball mill jar. Seal the ball mill jar, and mill it through a planetary ball mill for 12 hours at a speed of 500 rpm, and wash and dry the milled sample according to the method described in Example 1.

[0048] Weigh the active material (graphyne powder), conductive agent (Super P fine powder) and binder (polyvinylidene fluoride) with a mass ratio of 8:1:1, add solvent (1-methyl-2-pyrrolidone ), stirred and mixed into a slurry under a dry atmosphere. Apply the slurry evenly on the copper foil, place it in a vacuum drying oven and dry it at 60°C for 24 hours, cut into discs with a diameter of 14 mm, weigh them and assemble them into CR2016 in a glove box filled with argon. button battery. Among them, metallic lithium was used as the counter electrode, 1 M LiPF 6 The EC / DMC (1:1 volume ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com