Method for transforming carbon dioxide into chemical energy source substance

A technology of material and carbon powder, which is applied in the field of converting carbon dioxide into chemical energy materials, can solve the problems of inactivation due to carbon formation on the surface of the catalyst, difficulty in enlarging production capacity, and increasing environmental load, etc., so as to improve the conversion rate of CO2 and electric energy Effects of efficiency, stable CO production, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

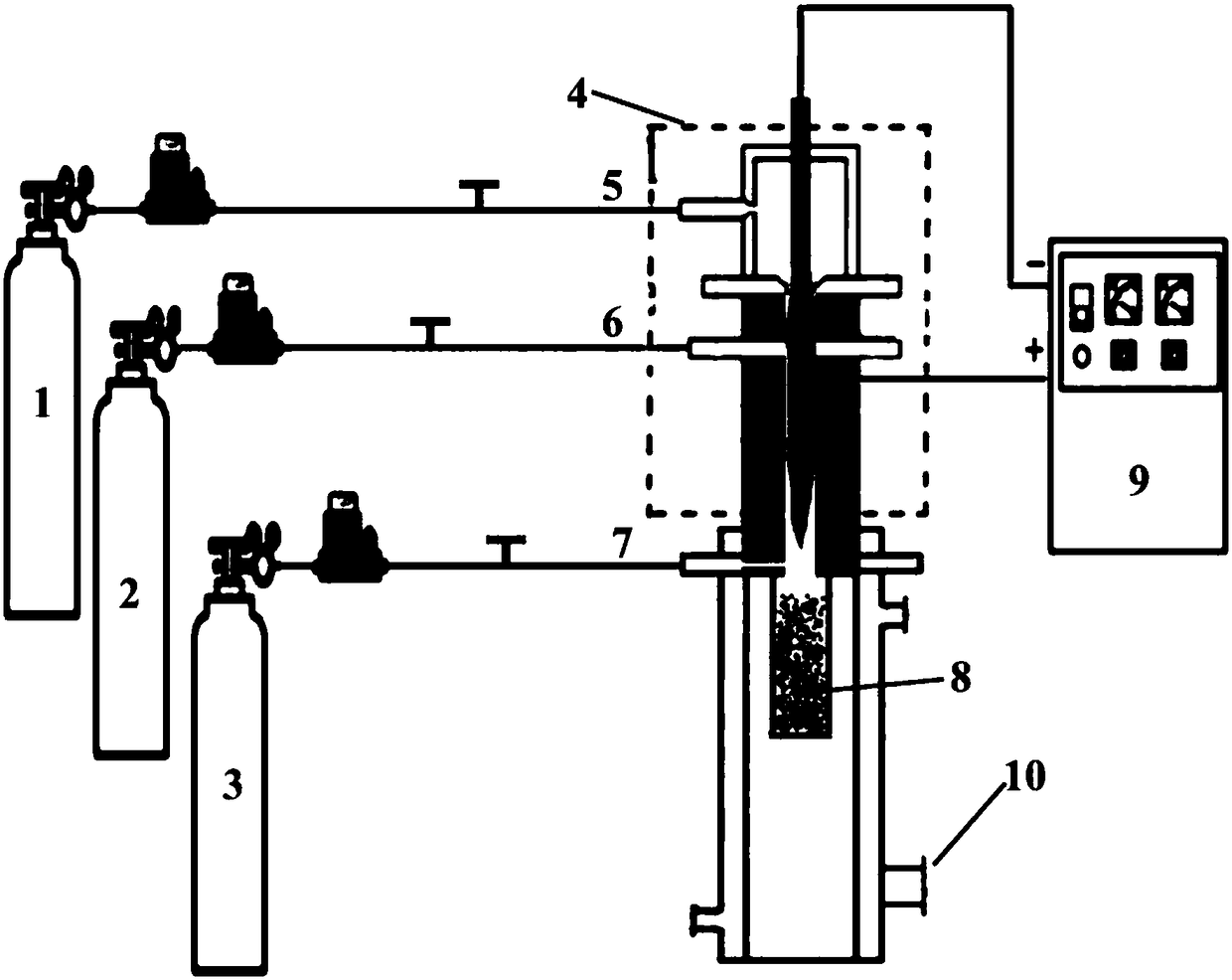

[0042] Fill the coke particles in the fixed-bed reactor 8, close the reaction auxiliary gas 3, and gas 1 (Ar) with the flow velocity of 25L / min, gas 2 (CO 2 ) into 4 from 5 and 6 at a flow rate of 25L / min, turn on the plasma power supply 9, which is a DC discharge, adjust the output power to 14kW, and form a stable high-temperature CO in 4 with a temperature of 3100K 2 The plasma jet flows into the fixed-bed reactor 8, and the hot jet flows through the fixed-bed reactor 8 loaded with carbon in advance, and reacts with the carbon to generate CO, which flows out of the fixed bed. After 6 minutes, samples are taken at the gas analysis sampling point 10 for analysis and monitoring of the reaction product , and finally realize the conversion of CO with high efficiency and low energy consumption 2 For CO purposes, CO 2 The conversion rate can reach 95%, and the electric energy consumption for producing CO is 320kJ / mol (CO).

Embodiment 2

[0044] Coke particles are filled in the fixed bed reactor 8, and the gas 1 (N 2 ) at a flow rate of 25L / min, gas 2 (CO 2 ) into 4 from 5 and 6 respectively at a flow rate of 25L / min, turn on the plasma power supply 9, which is DC discharge, adjust the output power to 14kW, and form a stable temperature in 4 that is a high temperature CO of 3100K 2 Plasma jet flow out 4, flow into fixed bed reactor 8, open reaction auxiliary gas 3 (H 2 ), send hydrogen gas into the hot plasma jet at a flow rate of 25L / min and complete the reaction in the fixed bed reactor 8 to generate CO. After 6 minutes, take a sample at the gas analysis sampling point 10 to analyze and monitor the reaction product, and finally realize the high efficiency of electric energy. , low energy consumption to convert CO 2 For CO purposes, CO 2 The conversion rate can reach 60%, and the electricity consumption for producing CO is 900kJ / mol (CO).

Embodiment 3

[0046] Coke particles are filled in the fixed bed reactor 8, and the gas 1 (N 2 ) at a flow rate of 25L / min, gas 2 (CO 2 ) into 4 from 5 and 6 respectively at a flow rate of 25L / min, turn on the plasma power supply 9, which is DC discharge, adjust the output power to 14kW, and form a stable temperature in 4 that is a high temperature CO of 3100K 2 The plasma jet flows out 4, flows into the fixed bed reactor 8, and opens the reaction auxiliary gas 3 (CH 4 ), send methane into the hot plasma jet at a flow rate of 25L / min and complete the reaction in the fixed-bed reactor 8 to generate CO. After 6 minutes, take a sample at the gas analysis sampling point 10 to analyze and monitor the reaction product, and finally realize the high-efficiency electric energy , low energy consumption to convert CO 2 For CO purposes, CO 2 The conversion rate can reach 80%, and the electricity consumption for producing CO can be reduced to 400kJ / mol (CO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com