Preparation technology of propionic acid

A preparation process, propionic acid technology, applied in the field of propionic acid preparation process, can solve the problems of harsh operating conditions, low production efficiency, high cost, etc., achieve the effect of reducing production cost, improving production efficiency and purity, and facilitating industrial promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

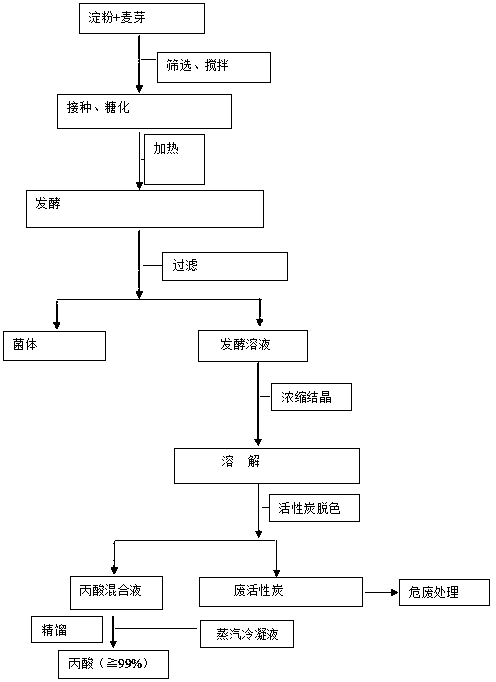

Image

Examples

Embodiment 1

[0017] Propionic acid preparation process described in the present embodiment, it specifically comprises the following steps:

[0018] (1) Sterilization treatment: steam the fermenter with 0.6Mpa steam for 30 minutes, blow it with sterile air, and dry it;

[0019] (2) Inoculation and saccharification: add 30m 3 deionized water, and then add the screened starch and maltose at a uniform speed, the weight-to-component ratio of starch and maltose is 3:1, add 30 tons of starch and maltose, stir while adding, stir and mix evenly, add steam to cook For 6 hours, the cooking temperature is 120°C, and the steam pressure is 0.2MPa; then after cooling down to 85-90°C, add amylase, glucoamylase and Bacillus, stir evenly, and then put it into a fermenter for closed fermentation;

[0020] (3) Fermentation: After inoculation and saccharification, the starch and maltose are kept at 50°C in the fermentation tank, and sterile air is added, and the air flow rate is controlled at 5m 3 / h, reple...

Embodiment 2

[0026] Propionic acid preparation process described in the present embodiment, it specifically comprises the following steps:

[0027] (1) Sterilization treatment: steam the fermenter with 0.6Mpa steam for 35 minutes, blow it with sterile air, and dry it;

[0028] (2) Inoculation and saccharification: add 40m 3 Then add the screened starch and maltose at a uniform speed, the weight ratio of starch and maltose is 3:1, add 40 tons of starch and maltose, stir while adding, stir and mix evenly, add steam to cook for 7 hours , the cooking temperature is 130°C, the steam pressure is 0.2MPa; then the temperature is lowered to 90°C, amylase, glucoamylase and bacillus are added, after stirring evenly, it is sent into a fermenter for closed fermentation;

[0029] (3) Fermentation: After inoculation and saccharification, the starch and maltose are kept at 60°C in the fermentation tank, and sterile air is added, and the air flow rate is controlled at 5m 3 / h, replenish liquid ammonia, ...

Embodiment 3

[0035] Propionic acid preparation process described in the present embodiment, it specifically comprises the following steps:

[0036] (1) Sterilization treatment: steam the fermenter with 0.6Mpa steam for 40 minutes, blow it with sterile air, and dry it;

[0037] (2) Inoculation and saccharification: add 50m 3 deionized water, and then add the screened starch and maltose at a uniform speed, the weight-to-component ratio of starch and maltose is 3:1, add 50 tons of starch and maltose, stir while adding, stir and mix evenly, add steam to cook For 8 hours, the cooking temperature is 145°C, and the steam pressure is 0.2MPa; then after cooling down to 90°C, add amylase, glucoamylase and Bacillus, stir evenly, and then put it into a fermenter for closed fermentation;

[0038] (3) Fermentation: After inoculation and saccharification, the starch and maltose are kept at 70°C in the fermentation tank, and sterile air is added, and the air flow rate is controlled at 5m 3 / h, replenis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com