Magnetic nanoparticles and application thereof in preparing magnetic solid-phase carriers

A technology of magnetic nanoparticles and solid-phase carriers, which is applied in the preparation method of peptides, the manufacture of inductors/transformers/magnets, electrical components, etc., and can solve problems that affect the performance of peptides, easy aggregation of magnetic particles, and insufficient surface hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The synthetic method of magnetic nanoparticle described in the present embodiment, comprises the following steps:

[0036] (1) 12g FeCl 3 ·6H 2 O and 4.9 g FeCl 2 4H 2 O was dissolved in 50mL deionized water, and then at 80°C under N 2In the atmosphere, quickly add 50ml of ammonia water to the above solution under vigorous stirring, and mix well;

[0037] After stirring for 30 minutes, 2 g of oleic acid was added to the above mixture, and the suspension was kept at 80° C. for 1 hour. After the reaction, the magnetic nanoparticles were washed with deionized water until neutral, and vacuum-dried to obtain oleic acid-modified Superparamagnetic Fe 3 o 4 particle;

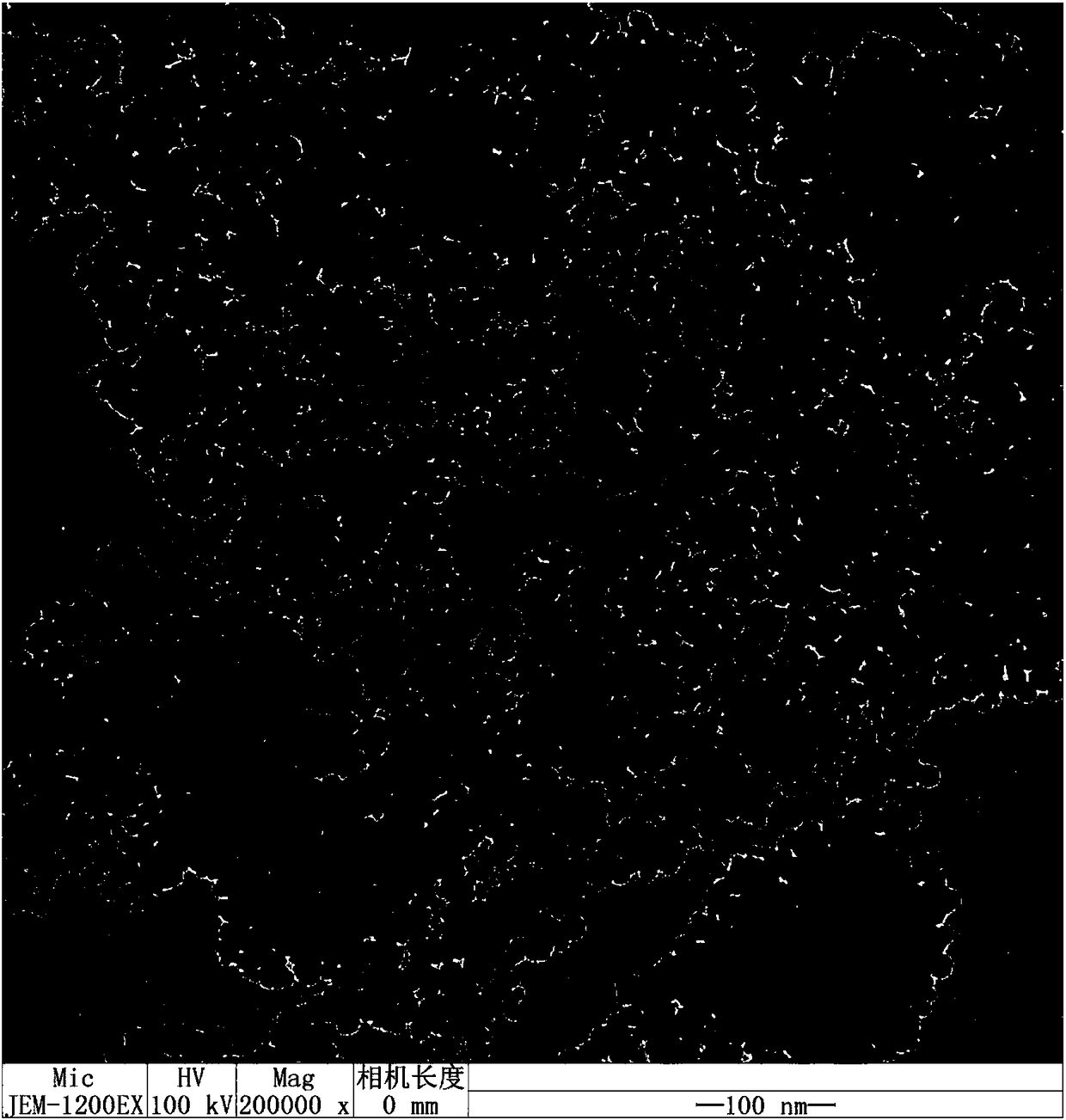

[0038] The obtained oleic acid-modified superparamagnetic Fe 3 o 4 Particles were subjected to microscopic morphology analysis, and the results were as follows: figure 1 As can be seen from the figure, the superparamagnetic Fe modified by oleic acid 3 o 4 The particles have good monodispersity, unifor...

Embodiment 2

[0044] The synthetic method of magnetic nanoparticle described in the present embodiment, comprises the following steps:

[0045] (1) 12g FeCl 3 ·6H 2 O and 4.9 g FeCl 2 4H 2 O was dissolved in 50mL of deionized water, then at 70°C under N 2 In the atmosphere, quickly add 50mL ammonia water to the above solution under vigorous stirring, and mix well;

[0046] After stirring for 20 minutes, 2 g of oleic acid was added to the above mixture, and the suspension was kept at 70°C for 2 hours. After the reaction, the magnetic nanoparticles were washed with deionized water until neutral, and vacuum-dried to obtain oleic acid-modified Superparamagnetic Fe 3 o 4 particle;

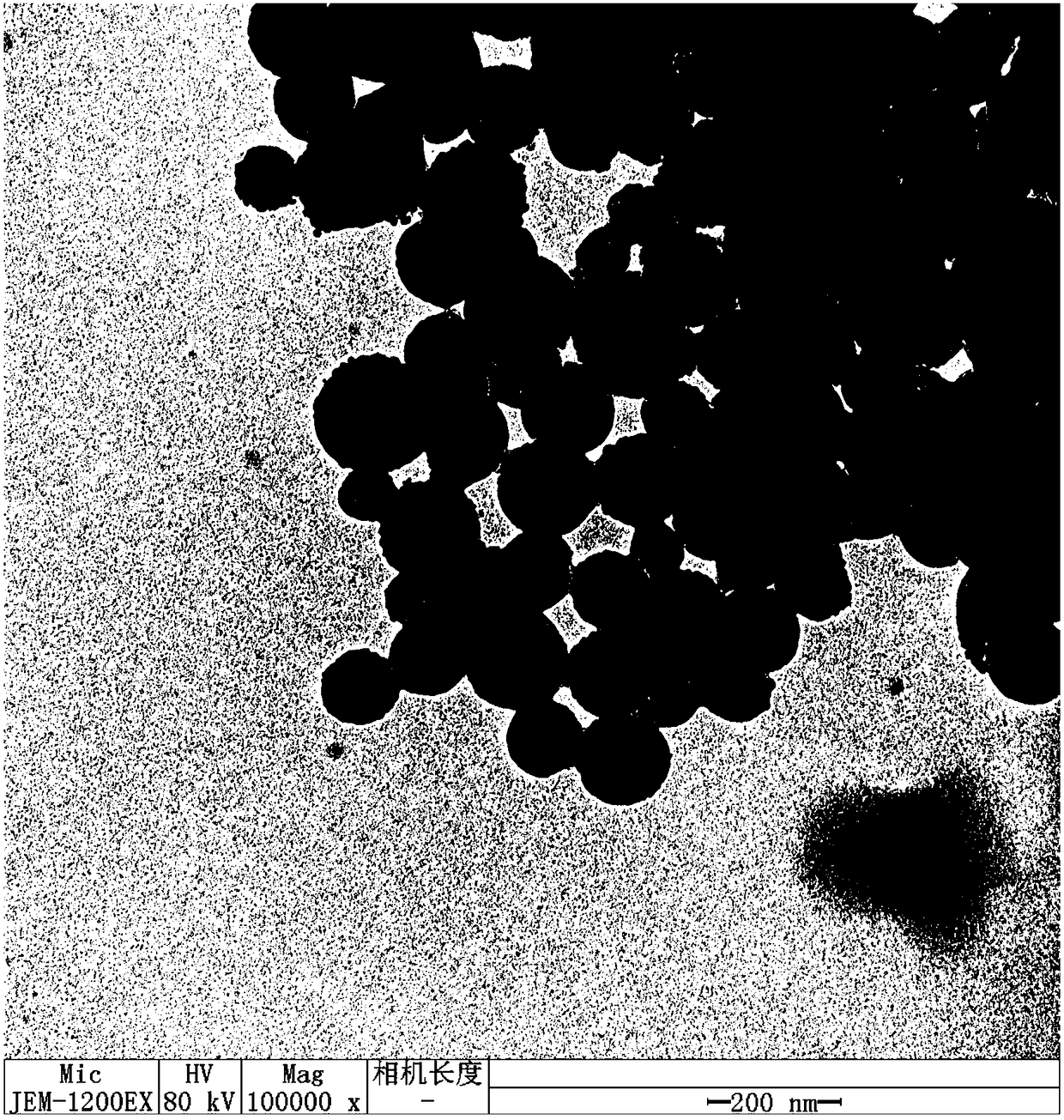

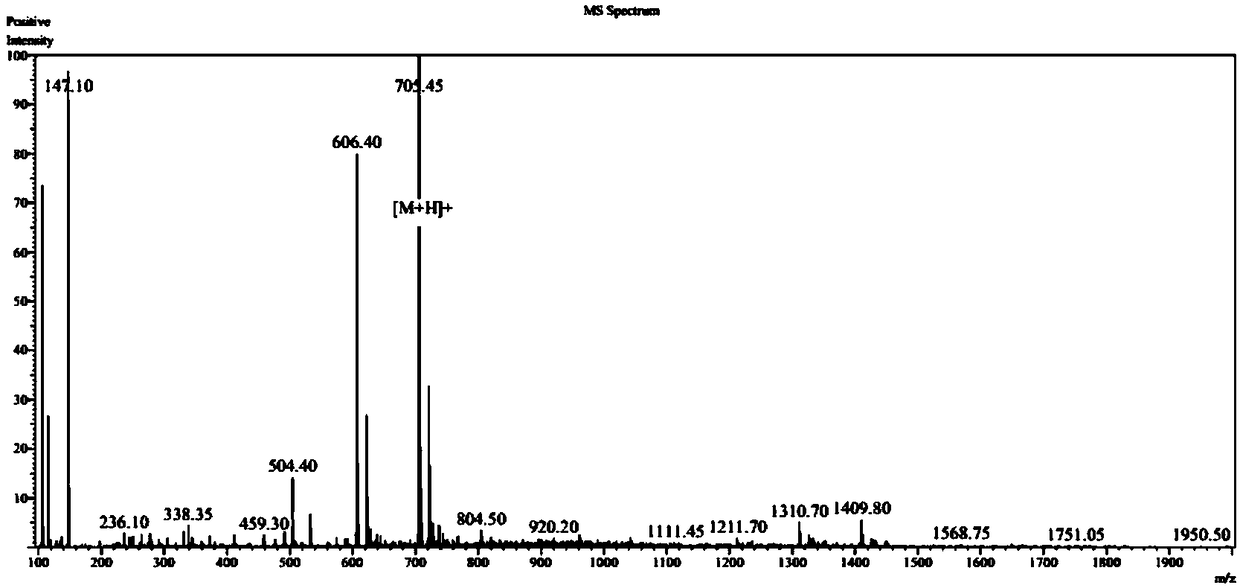

[0047] (2) the obtained oleic acid modified superparamagnetic Fe 3 o 4 The particles are dispersed into n-hexane to form a magnetic fluid (the solid-to-liquid ratio of the magnetic fluid and solvent is controlled to be 0.125g / mL), and styrene, 4-(4-vinylbenzyl oxybenzyl alcohol) and divinylbenzene (DVB) (mo...

Embodiment 3

[0051] The synthetic method of magnetic nanoparticle described in the present embodiment, comprises the following steps:

[0052] (1) 12g FeCl 3 ·6H 2 O and 4.9 g FeCl 2 4H 2 O was dissolved in 50mL deionized water, and then at 80°C under N 2 In the atmosphere, quickly add 50mL ammonia water to the above solution under vigorous stirring, and mix well;

[0053] After stirring for 30 minutes, 2 g of oleic acid was added to the above mixture, and the suspension was kept at 80° C. for 2 hours. After the reaction, the magnetic nanoparticles were washed with deionized water until neutral, and vacuum-dried to obtain oleic acid-modified Superparamagnetic Fe 3 o 4 particle;

[0054] (2) the obtained oleic acid modified superparamagnetic Fe 3 o 4 The particles are dispersed into n-hexane to form a magnetic fluid (the solid-to-liquid ratio of the magnetic fluid and solvent is controlled to be 0.125g / mL), and styrene, 4-(4-vinylbenzyl Oxybenzyl alcohol) and divinylbenzene (DVB) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com