Karat-grade diamond synthesizing device and synthesizing method thereof

A synthesis device and diamond technology, applied in the direction of using atmospheric pressure to chemically change substances, chemical instruments and methods, and the application of ultra-high pressure processes, etc., can solve the problem of stable production of carat-level diamonds and the speed of carbon source deposition Different content, large radial and longitudinal temperature differences, etc., to achieve the effect of ensuring temperature field, good economic benefits, and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

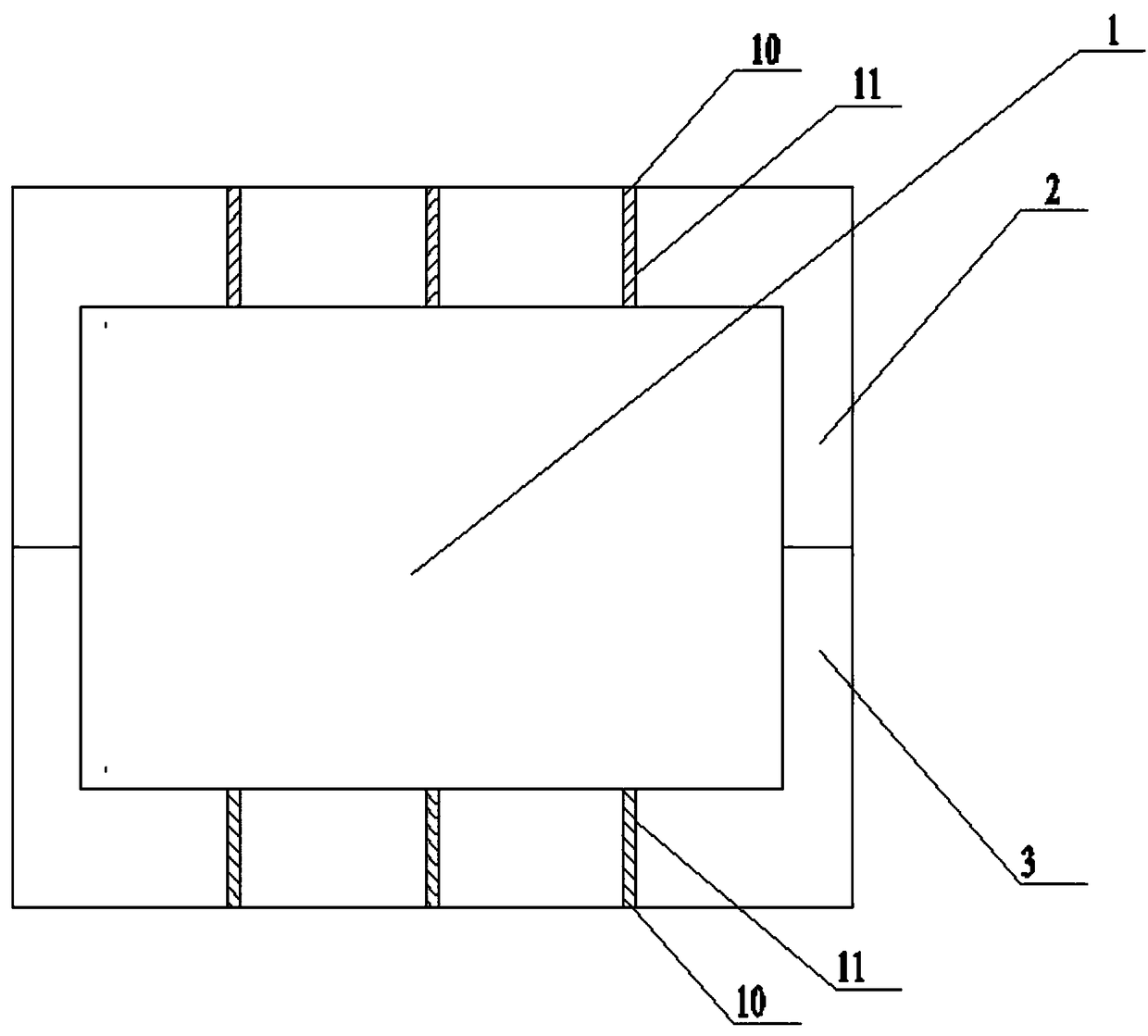

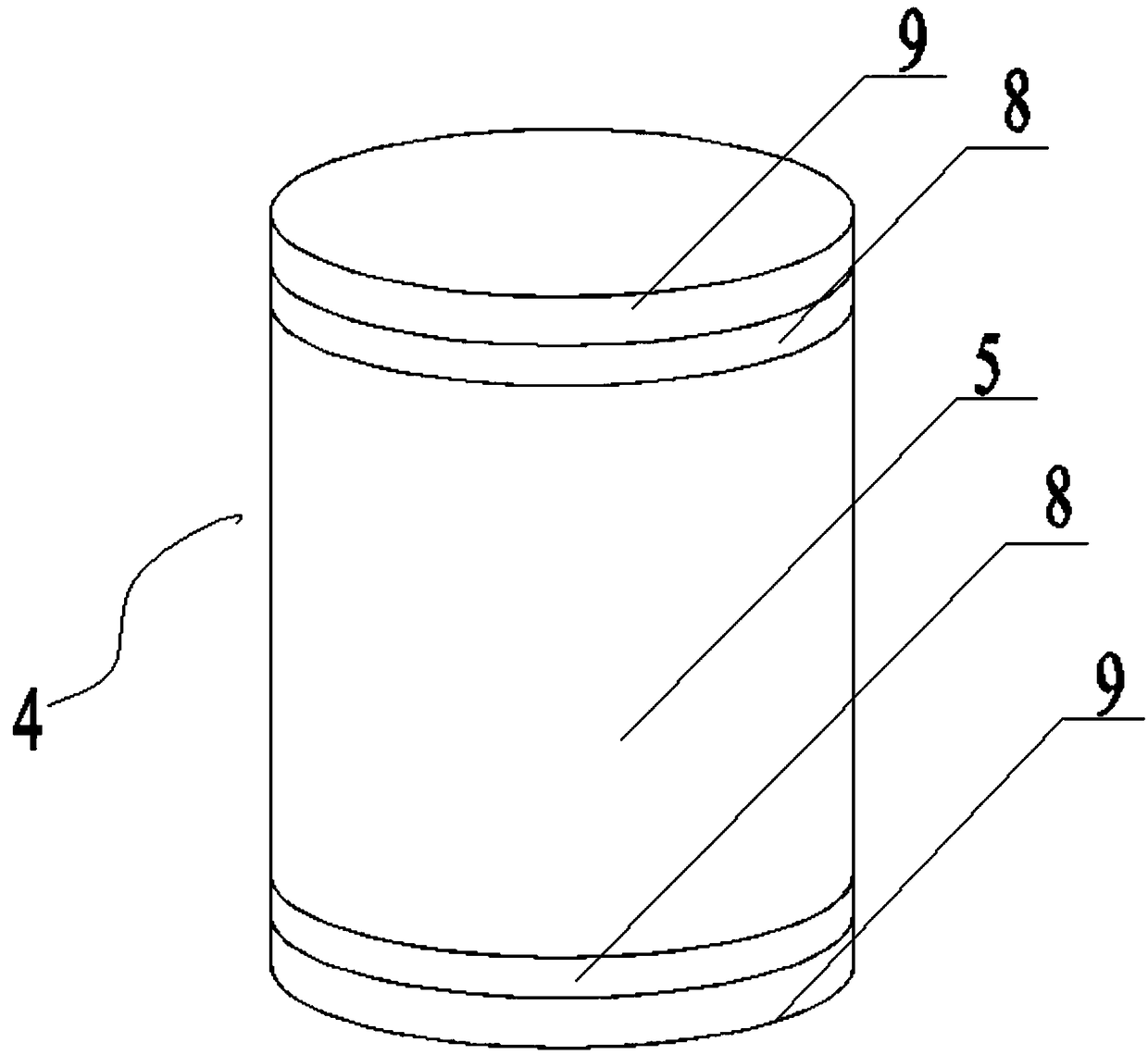

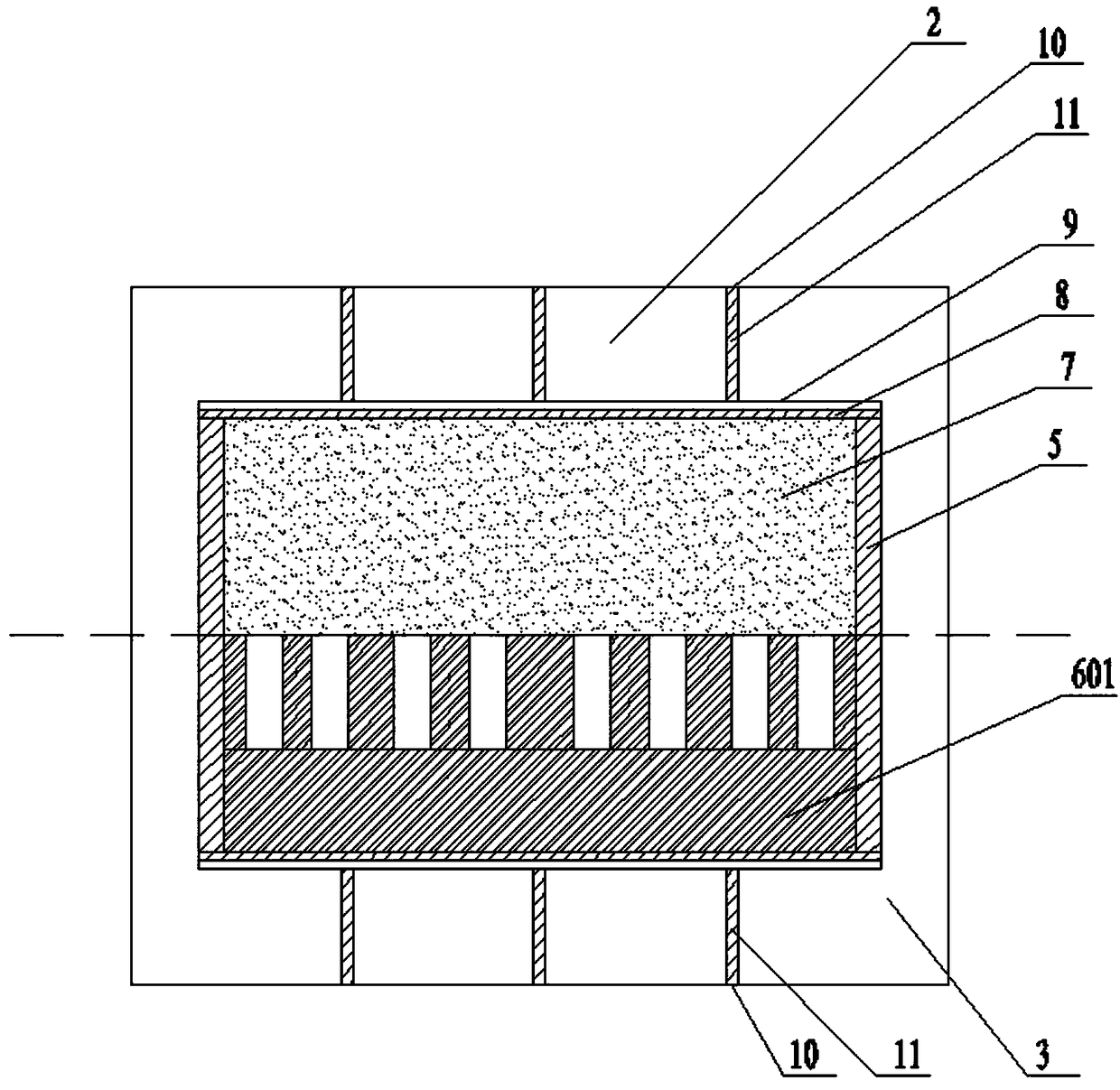

[0050] A device for artificially synthesizing carat-grade diamonds, such as figure 1 , figure 2 , image 3 , Figure 3-1 , Figure 3-2 As shown, the device includes a pyrophyllite cavity 1, the pyrophyllite cavity 1 is formed by fastening the upper half pyrophyllite cup body 2 and the lower half pyrophyllite cup body 3, the upper half pyrophyllite cup body 2 and the The cup bottom of lower half pyrophyllite cup body 3 is all provided with a plurality of pyrophyllite through-holes 10, the diameter of pyrophyllite through-holes is 4~6mm, is provided with conductive post 11 in the through-hole, and the diameter and length of described conductive post 11 are all with The diameter and length of pyrophyllite through hole 10 are consistent (the cup bottom thickness of pyrophyllite cup body is 10~15mm, and the length of pyrophyllite through hole is 10-15mm, and the wall thickness of pyrophyllite cup body is 8~9mm); The device also includes The synthesis column 4 arranged in the p...

Embodiment 2

[0055] The same parts in embodiment 2 and embodiment 1 have the same functions, and for the sake of brevity, they will not be repeated.

[0056] A synthetic device for carat diamonds, such as Figure 4 As shown, the heating pipe is sequentially provided with a second thermal insulation heating sheet 12, a honeycomb module 602 with through holes, a first thermal insulation pressure transmission sheet 7, the second thermal insulation pressure transmission sheet 12, The sum of the heights of the honeycomb module 602 with through holes and the first thermal insulation and pressure transmission sheet 7 is equal to the height of the heating pipe 5;

[0057] Such as Figure 6 As shown, the honeycomb module 602 with through holes includes a module body and a plurality of through holes 6021 arranged at intervals along the longitudinal direction of the module body, and the interval between the through holes is 2 to 4 mm; the diameter of the through holes 6021 is 6 ~15m (change the dia...

Embodiment 3

[0061] In this embodiment, the heating sheet is a sheet structure (the diameter of which is the same as the outer diameter of the heating tube) cut from a high-purity graphite rod by a common method.

[0062] Both the first thermal insulation and pressure transmission sheet and the second thermal insulation and pressure transmission sheet are cylinders pressed by high-purity magnesium oxide; the honeycomb module is composed of magnesia with a mass content of 80% and a mass content of 20% A cylinder with a hole (the hole is a blind hole or a through hole from the upper part downward along the longitudinal direction of the cylinder) made of zirconia mixed and pressed by common methods;

[0063] The crystal bed is a cylinder formed by pressing high-purity magnesium oxide by a common method, and the catalyst sheet is composed of Fe with a mass content of 50-70% and Ni with a mass content of 30-50% and trace elements commonly used The method is made by mixing and pressing, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com