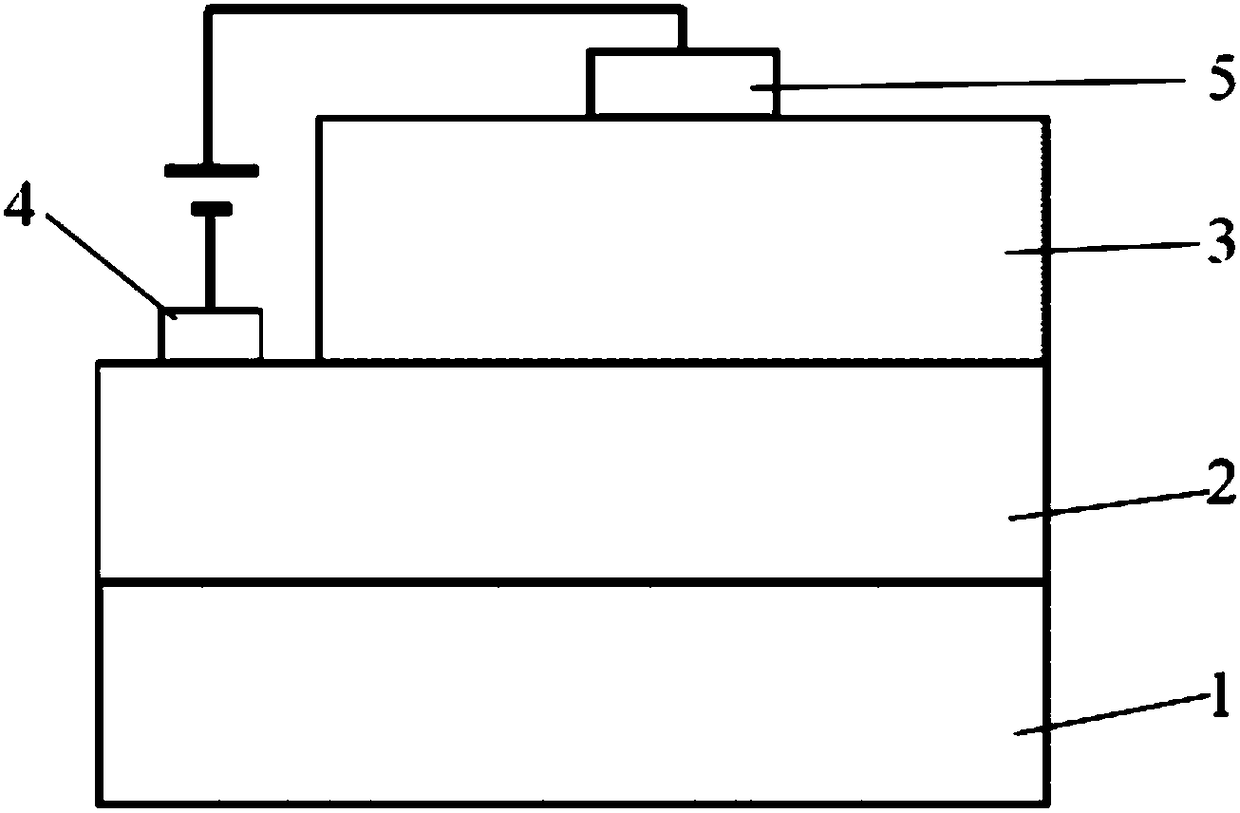

Deep-ultraviolet detector based on lead-free double-perovskite film, and preparation method

A lead-free double perovskite, deep ultraviolet light technology, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve the problems of structural instability and lead toxicity, and achieve excellent performance and environmental friendliness. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) cleaning substrate 1, the adopted substrate is double-sided polished Al 2 O 3 substrate.

[0033] Al with double throw 2 O 3 A single wafer is used as the substrate 1, and it is chemically cleaned. The cleaning steps are: put the substrate in acetone and ethanol solutions for ultrasonic cleaning for 5 minutes, and then recirculate once; Blow dry with nitrogen for later use.

[0034] (2) An n-type electron supply layer 2 is prepared.

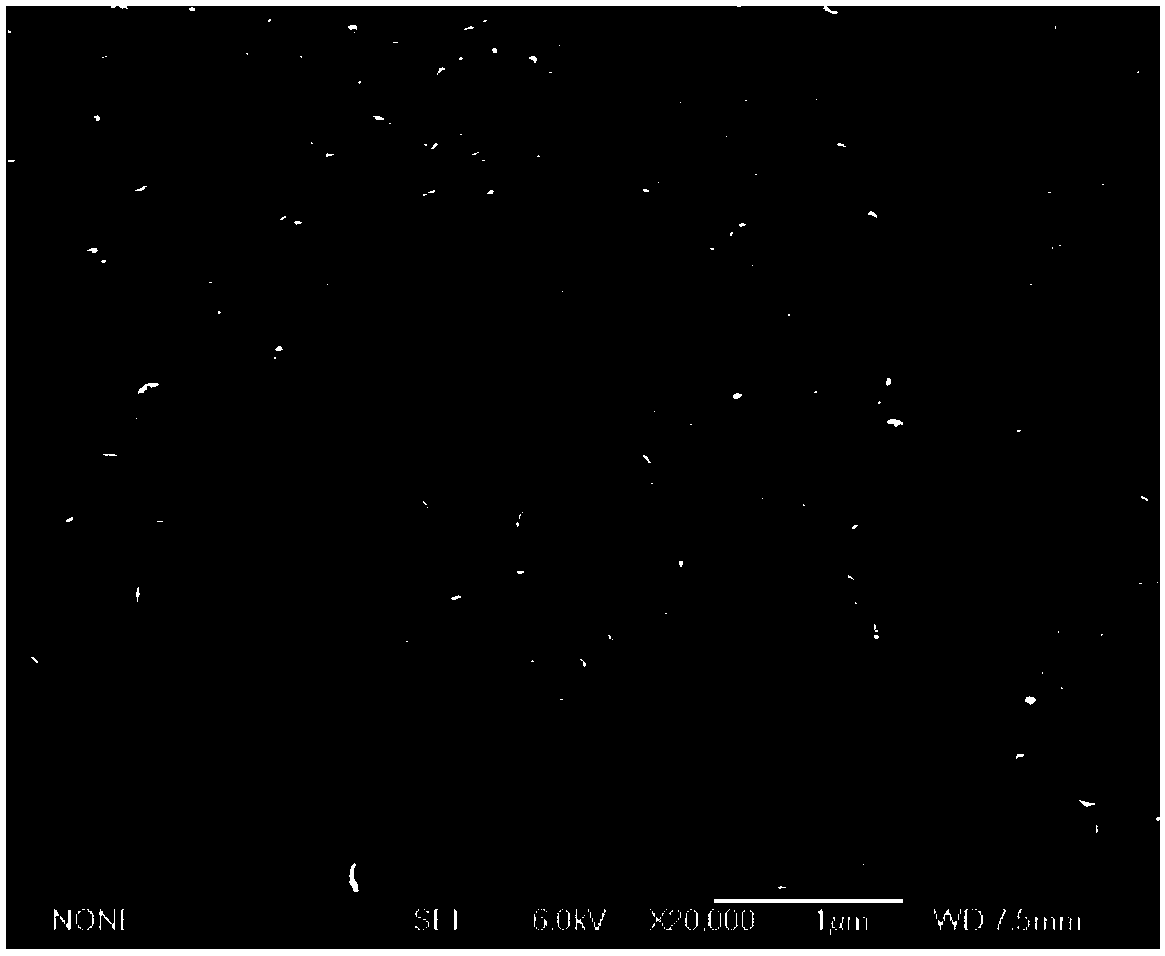

[0035] Double-throw Al by RF magnetron sputtering 2 O 3 The deposition of the ZnO electron supply layer is completed on the substrate 1, and the specific steps are: install ZnO:Al 2 O 3 (mass fraction: Al 2 O 3: ZnO=1.2:98.8%) ceramic target, adjust the distance between the target and the substrate to 10 cm; turn on the mechanical pump, vacuumize the cavity, when the vacuum of the cavity is lower than 10 Pascals, turn on the molecular The pump continues to evacuate until the cavity vacuum is lower than 2.0×10 -3 Pascal; fee...

Embodiment 2

[0044] (1) cleaning substrate 1, the adopted substrate is double-sided polished Al 2 O 3 substrate.

[0045] In this embodiment, double-throwing Al 2 O 3 The cleaning method is the same as in Example 1.

[0046] (2) The n-type electron supply layer 2 is prepared, and a GaN semiconductor material is used as the electron supply layer.

[0047] A double-throw Al 2 O 3 The epitaxial growth of the GaN electron transport layer 2 is completed on the substrate 1 . The specific growth process is as follows: the cleaned double-polished Al 2 O 3 The substrate 1 is placed in the reaction chamber; then, the sample is heated to 1060°C, and hydrogen gas (100 sccm) is introduced into the Al 2 O 3 The surface of the substrate 1 is subjected to high-temperature treatment to remove impurities on the surface; then, the temperature of the sample is lowered to 550° C. to grow a GaN low-temperature nucleation layer with a thickness of 30 nanometers; and the temperature is raised to 1035° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electron concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com