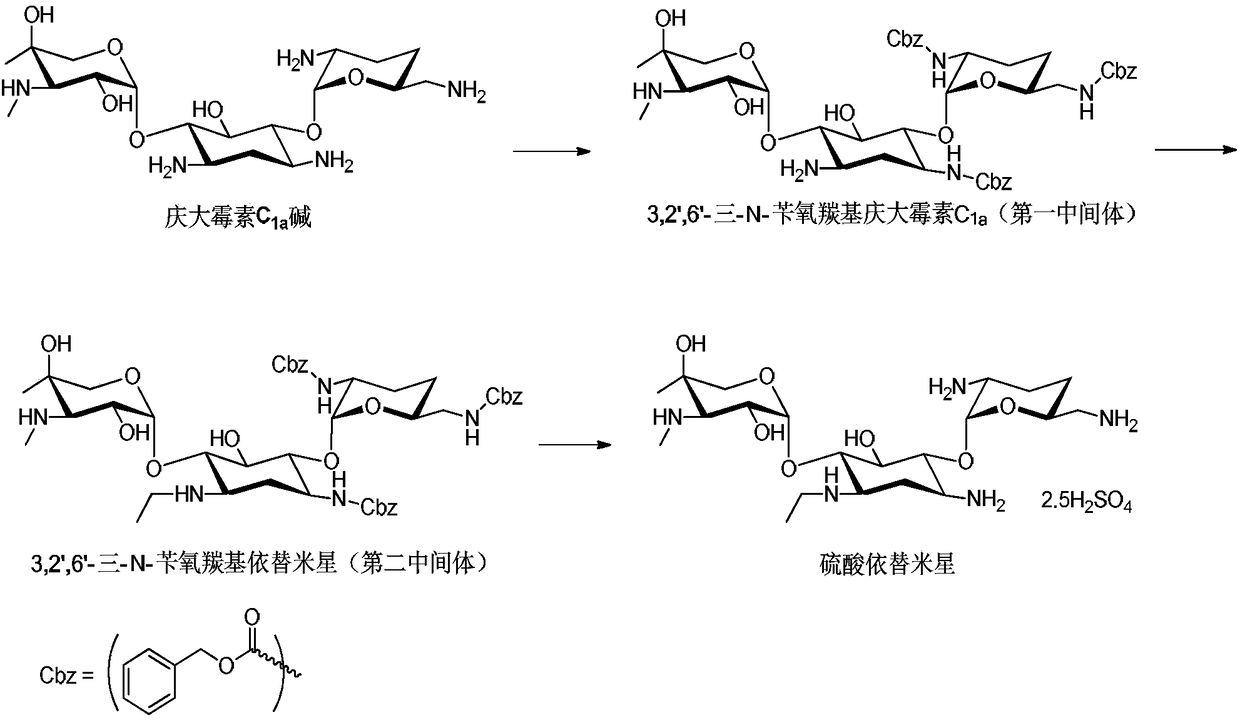

Preparation method of etimicin sulfate

A technology of etimicin sulfate and gentamicin, applied in the field of medicine, can solve problems such as high requirements for instruments, hindering reactions, and affecting reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Preparation of the first intermediate

[0069] Gentamicin C 1abase, add gentamicin C 1a Ethanol 10 times the weight of the base, stir to dissolve, add gentamicin C 1a 3 equivalents of cobalt acetate in alkali molar weight, stirred to obtain reaction solution 1, added gentamicin C 1a 3 equivalents of benzyloxycarbonyloxyphthalimide in the molar amount of base, stirred and reacted for 2h to obtain reaction solution 2, added gentamicin C 1a Chloroform 10 times the weight of the base, Gentamicin C 1a Ammonia water (mass fraction 8%-12%) 5 times the weight of the base was stirred for 2 hours, separated, and the organic phase was concentrated under reduced pressure at a temperature of 70° C. and a vacuum degree ≥ 0.085 MPa to obtain the first intermediate.

[0070] Two, the preparation of the second intermediate

[0071] Take 5 equivalents of sodium borohydride in the molar amount of the first intermediate, add chloroform that is 20 times the weight of the first inter...

Embodiment 2

[0083] 1. Preparation of the first intermediate

[0084] Gentamicin C 1a base, add gentamicin C 1a Methanol 12 times the weight of the base, stir to dissolve, add gentamicin C 1a 6 equivalents of zinc acetate dihydrate in alkali molar weight, stirred to obtain reaction solution 1, added gentamicin C 1a 4 equivalents of benzyloxycarbonyloxysuccinimide in the molar amount of the base, stirred and reacted for 3h to obtain reaction solution 2, adding gentamicin C 1a Dichloromethane 15 times the weight of the base, Gentamicin C 1a Ammonia water (mass fraction 12%-16%) 8 times the weight of the base was stirred for 2 hours, separated, and the organic phase was concentrated under reduced pressure at a temperature of 70° C. and a vacuum degree ≥ 0.085 MPa to obtain the first intermediate.

[0085] Two, the preparation of the second intermediate

[0086] Take 7 equivalents of sodium borohydride in the molar amount of the first intermediate, add dichloromethane 23 times the weight ...

Embodiment 3

[0091] 1. Preparation of the first intermediate

[0092] Gentamicin C 1a base, add gentamicin C 1a Dimethyl sulfoxide 15 times the weight of the base, stir to dissolve, add gentamicin C 1a 8 equivalents of copper acetate in alkali molar weight, stirred to obtain reaction solution 1, added gentamicin C 1a Add benzyl chloroformate to 5 equivalents of the molar amount of base, stir and react for 1h to obtain reaction solution 2, add gentamicin C 1a Toluene 12 times the weight of the base, Gentamicin C 1a Ammonia water (mass fraction 16%-20%) 10 times the weight of the base was stirred for 1 h, separated, and the organic phase was concentrated under reduced pressure at a temperature of 70° C. and a vacuum ≥ 0.085 MPa to obtain the first intermediate.

[0093] Two, the preparation of the second intermediate

[0094] Take 9 equivalents of sodium borohydride in the molar amount of the first intermediate, add toluene 23 times the weight of the first intermediate, stir, add 36 equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com