Reusable 3D printing material and its preparation method

A 3D printing and filler technology, applied in the preparation of materials for 3D printing, in the field of materials for 3D printing based on quadruple hydrogen-bonded supramolecular polymers, can solve problems such as the inability to apply temperature-sensitive models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

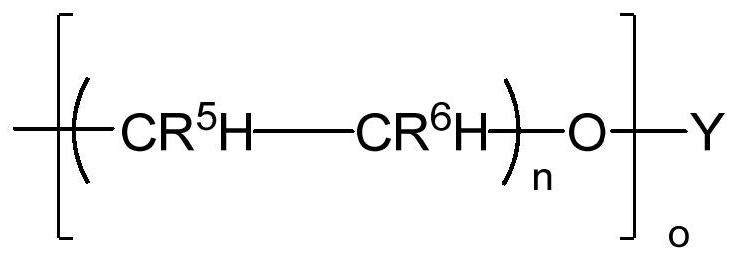

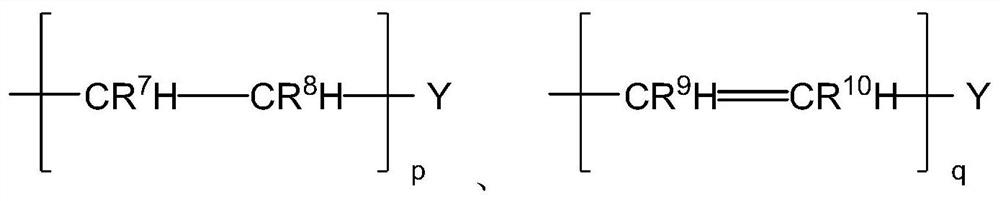

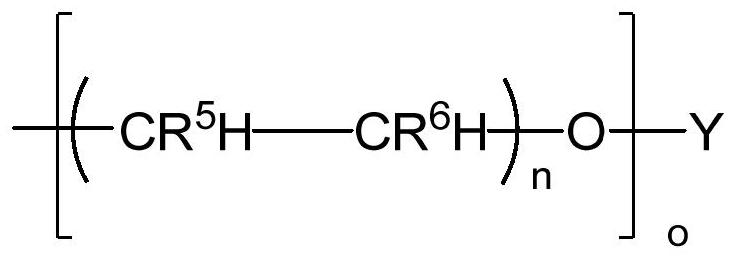

Method used

Image

Examples

preparation example Construction

[0080] Synthon preparation

[0081] 2-ureido-4[1H]-pyrimidinone can be prepared by reacting the corresponding isocytosine with the corresponding isocyanate. Isocytosine can be prepared by condensation reaction of corresponding β-ketoester with guanidine.

[0082]

[0083] [beta]-Ketoesters are prepared in a number of ways. Among the most commonly used are the following three

[0084] 1) Prepared by the alkylation of the divalent ions of the corresponding haloalkanes and ethyl forma(ethyl)acetate;

[0085] 2) It is prepared by first reacting the corresponding acid chloride with ethyl acetoacetate, and then deacylation of an acetyl fragment;

[0086] 3) The corresponding acid chloride reacts with monoethyl malonate potassium salt and magnesium ion salt, and then adds hydrogen ion to remove an acetyl fragment and prepare it with magnesium ion.

[0087] The process of reaction 1 is as follows

[0088]

[0089] Ethyl acetate and sodium hydride react in tetrahydrofuran to...

Embodiment 1

[0272] 1 is divided into the following groups

[0273] Polymer 1 200g

[0274] Nano calcium carbonate 20g

[0275] Coster KR312 (Red) 1g

[0276] 2 Preparation method

[0277] Add 2000mL of chloroform to dissolve and make a paste, concentrate to 500mL, and dry to obtain a uniformly dispersed supramolecular polymer-based 3D printing material.

[0278] The material can be extruded into filaments at 60°C after crushing.

Embodiment 2

[0280] 1 is divided into the following groups

[0281] Polymer 2 200g

[0282] Silica 20g

[0283] Cabot 2014 Black Mother 1g

[0284] 2 Preparation method

[0285] Add 2000mL of chloroform to dissolve and make a paste, concentrate to 500mL, and dry to obtain a uniformly dispersed supramolecular polymer-based 3D printing material.

[0286] The material can be extruded into filaments at 60°C after crushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com