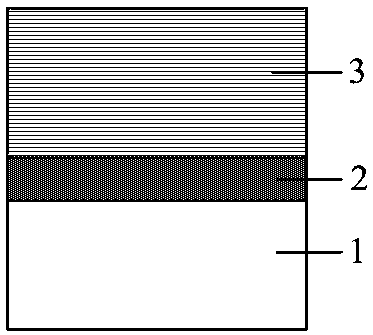

Extra-thick hydrogen-free diamond-like film and preparation method thereof

A diamond film, ultra-thick technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as poor bonding force, easy peeling of the film layer, film wear, etc., to enhance wear resistance. , to expand the scope of application, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing an ultra-thick hydrogen-free diamond-like film coating, comprising the following steps:

[0024] (1) Workpiece pretreatment. Grinding and polishing the workpiece, the surface roughness of the workpiece after grinding and polishing is Ra<0.1 μm, then the workpiece is ultrasonically cleaned with pure water and alcohol, and finally the workpiece is dried and placed on the turret of the vacuum ion plating furnace cavity;

[0025] (2) Ion cleaning. After vacuuming, the air pressure in the vacuum chamber is lower than 8×10 -4 After Pa, start the substrate turret, control the speed at 2~4rpm, pass in argon gas for argon ion glow cleaning, then reduce the flow rate of argon gas, turn on the Cr metal target, perform metal ion etching cleaning on the workpiece, and argon ion glow cleaning. The photodischarge cleaning conditions are as follows: air pressure is 2~4 Pa, substrate temperature is 300~400°C, substrate bias voltage is -800~-1000 V, duty cycle is...

Embodiment 1

[0030] Grind and polish the ball-milled cast iron piston ring workpiece to a roughness of Ra=80nm, first clean it with pure water and alcohol for 20 minutes, then dry it and place it on the turret of the vacuum ion plating furnace chamber, install a part of the elemental Cr on the arc target position Target, a part of the installation of high-purity graphite target, close the door of the vacuum chamber. Turn on the mechanical pump, Roots pump and molecular pump in turn to pump the vacuum chamber to 5×10 -4Pa, argon gas was introduced to 2.0Pa, the substrate temperature was heated to 350°C, a negative bias voltage of -1000V was applied to trigger glow discharge, and argon ion sputtering was performed for 20 minutes to clean. After glow cleaning, adjust the argon flow, control the vacuum chamber pressure at 0.3Pa, set the substrate bias to -900V, and the duty cycle to 40%, turn on the metal Cr target, and set the arc current of the target to 80A for metal ion engraving. etch cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com