Gold stamping paste and preparation method and application thereof

A slurry and formula technology, applied in the field of hot stamping slurry and its preparation, can solve the problems of low washing fastness, easy deformation and lace, poor washing fastness, etc. Change the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

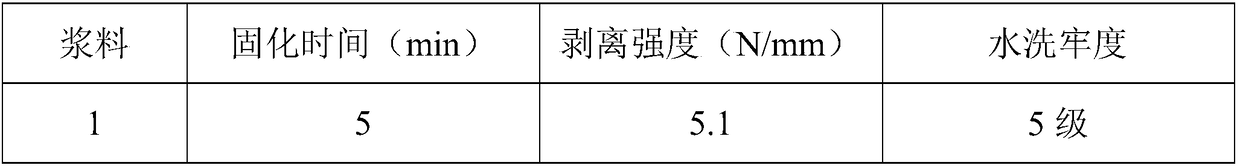

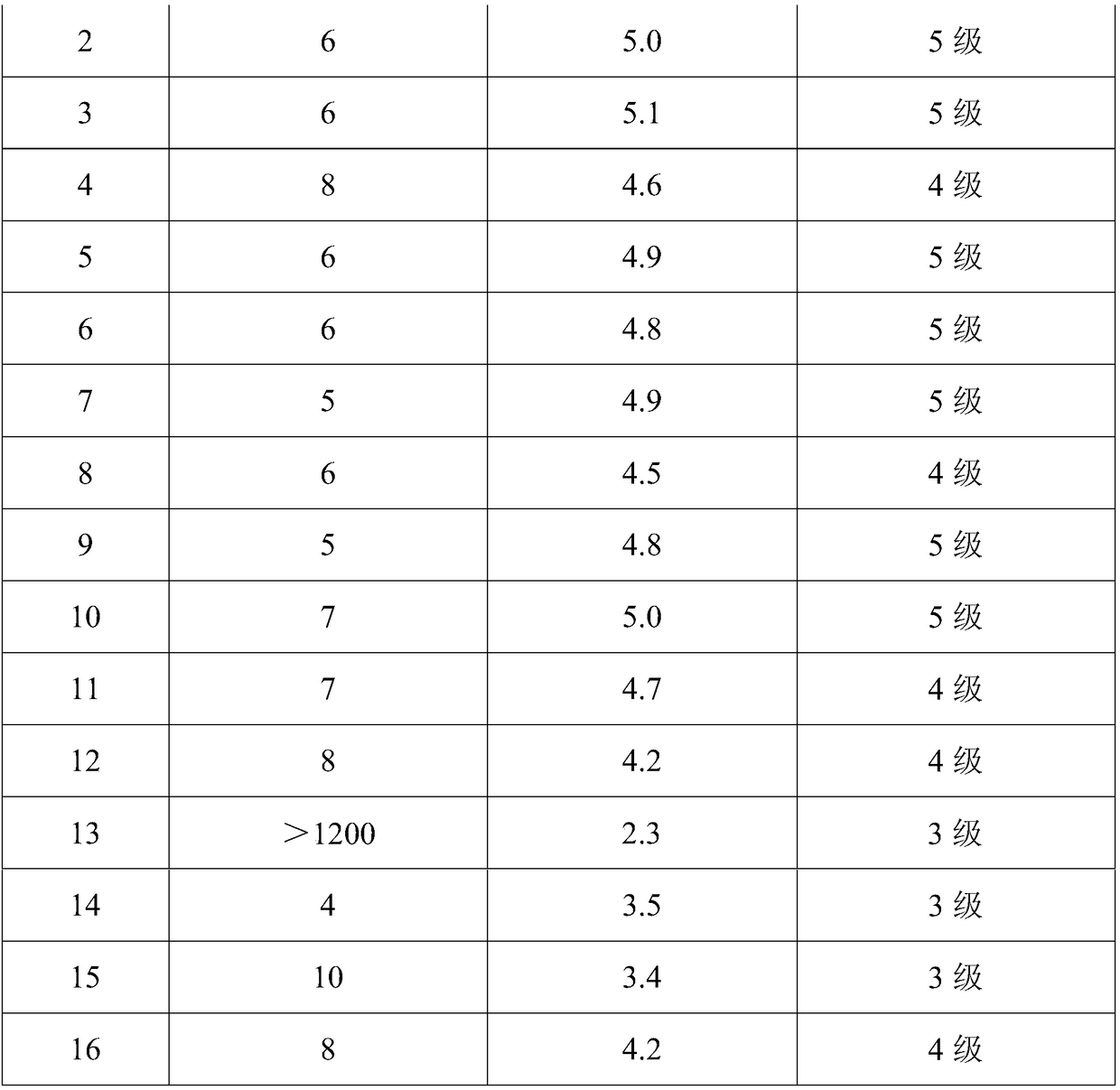

Examples

Embodiment 1

[0038] Prepare bronzing slurry 1 through the following steps:

[0039] Get the Q-50 type water-based acrylic emulsion produced by Dongguan Changlian Company, the RE-905 type water-based acrylic modified rosin emulsion produced by 200g Sihui Bangdeli Chemical Co., Ltd., 55g deionized water, 3g produced by U.S. Huntsman Thickener PTF, 30g film-forming agent glycerol, 6g pH regulator diethanolamine, 3g defoamer BYK-028 produced by BYK Company in Germany, 3g preservative Kathon, mix the above components, and use a stirring paddle with 300 Stir the obtained mixed solution at a speed of rpm, and when the viscosity of the mixed solution is greater than 30 Pa·s, filter the mixed solution to remove insoluble matter therein, quantify and package to obtain the slurry 1.

Embodiment 2

[0041] The only difference with Example 1 is that the addition amount of the aqueous acrylic emulsion is 500g.

[0042] Example 2 Slurry 2 was obtained.

Embodiment 3

[0044] The only difference from Example 1 is that the addition amount of the aqueous acrylic acid emulsion is 600 g, and the addition amount of the aqueous acrylic acid modified rosin solution is 300 g.

[0045] Example 3 Slurry 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com