Cellulose gel electrolyte material and a preparation method thereof

A technology of cellulose gel and electrolyte material, applied in the field of electrolyte material and its preparation, can solve the problems of inability to meet the development of science and technology and market, easy volatilization of solvent and long-term stability, difficult to achieve self-supporting film, etc., and achieve good liquid retention ability , good biocompatibility, the effect of improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 1 g of natural cellulose to 3 mL of sodium hydroxide solution with a mass fraction of 16%. After dispersing evenly, first keep it warm at 25°C for 10 minutes, then add 1 mL of carbon disulfide to it, react for 30 minutes, and wait for the product to transform After becoming an orange-red solid, add 6 mL of 4% sodium hydroxide solution, and stir for 10 minutes until it completely becomes a uniform orange-red viscose.

[0027] (2) Mix the viscose solution prepared in step (1) and deionized water at a weight ratio of 1:1, stir evenly, and then stand for crosslinking for 48 hours to obtain a cellulose gel electrolyte (XWD).

[0028] Such as figure 1 As shown, the prepared cellulose gel electrolyte contains a large amount of water and has certain toughness.

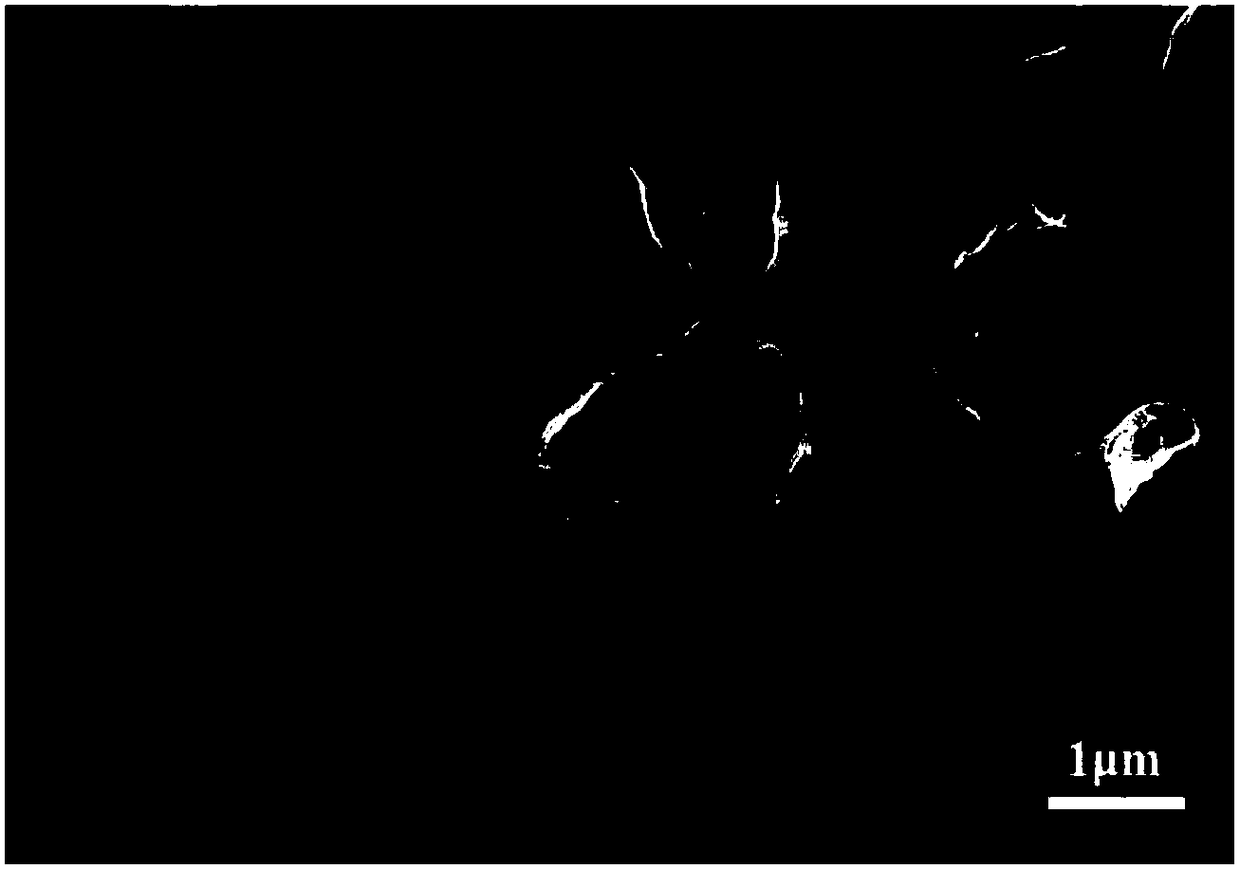

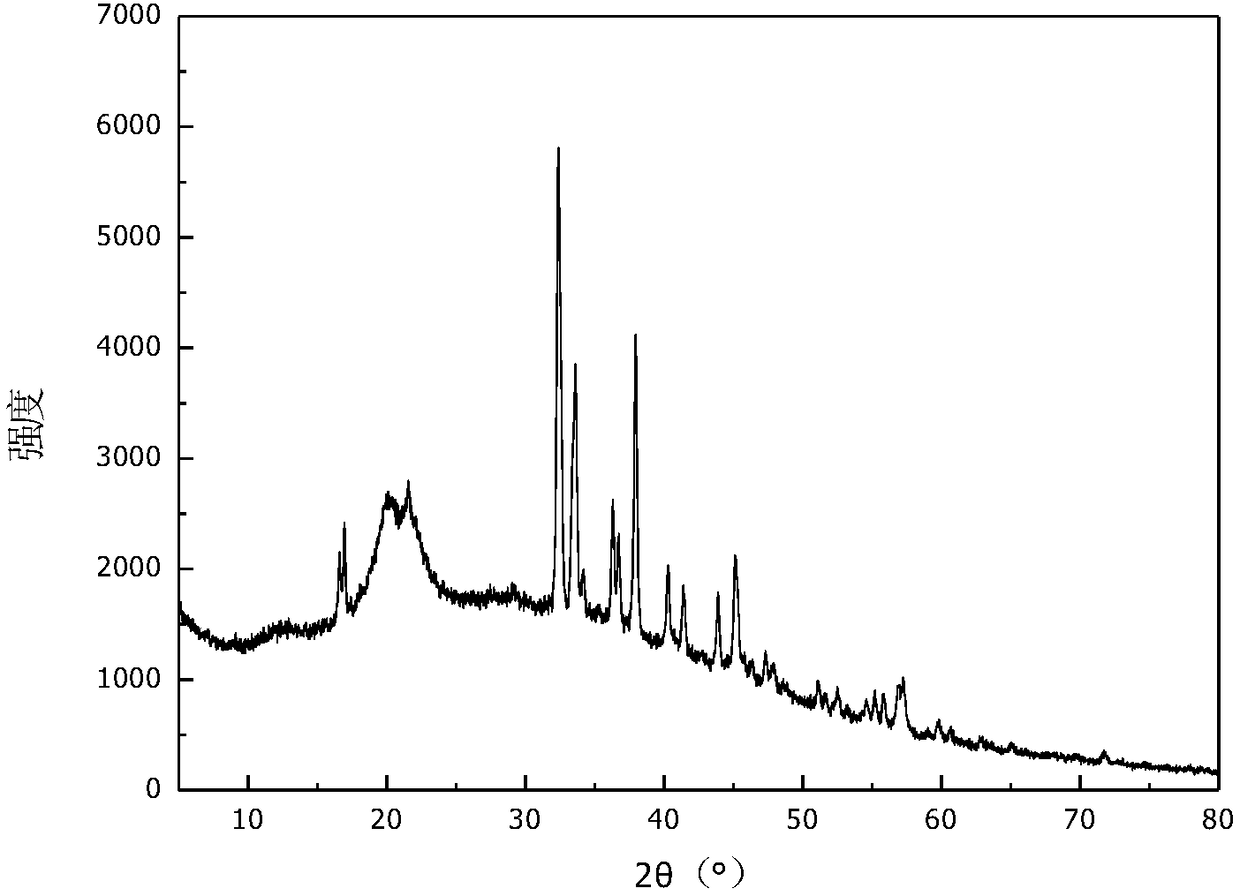

[0029] Such as figure 2 As shown, after drying and grinding the gel electrolyte, apply it on the conductive tape, and test it with a scanning electron microscope. It can be seen that the diameter of the inter...

Embodiment 2

[0033] (1) Add 1g of natural cellulose into 4mL of sodium hydroxide solution with a mass fraction of 18%. After the dispersion is even, first keep it warm at 26°C for 20min, then add 1.5mL of carbon disulfide to it, and react for 40min. After turning into an orange-red solid, add 8 mL of 4% sodium hydroxide solution, and stir for 10 minutes until it completely becomes a uniform orange-red viscose.

[0034] (2) Mix the viscose solution prepared in step (1) and deionized water at a weight ratio of 1:3, stir evenly, and then stand for cross-linking for 50 hours to obtain a cellulose gel electrolyte (XWD).

Embodiment 3

[0036] (1) Add 1g of natural cellulose to 5mL of 30% sodium hydroxide solution, after the dispersion is even, first keep it warm at 28°C for 20min, then add 2mL of carbon disulfide to it, react for 50min, and wait for the product to transform After turning into an orange-red solid, add 10 mL of 4% sodium hydroxide solution, and stir for 20 minutes until a uniform orange-red viscose is completely formed.

[0037] (2) Mix the viscose solution prepared in step (1) and deionized water at a weight ratio of 1:6, stir evenly, and then stand for cross-linking for 60 hours to obtain a cellulose gel electrolyte (XWD).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com