Preparation method of flexible large-area perovskite solar cell based on roller coating process

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor perovskite crystal quality, easy deformation of flexible substrates, uneven thickness, etc., to reduce toxicity hazards and complex processes. performance, saving battery production costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

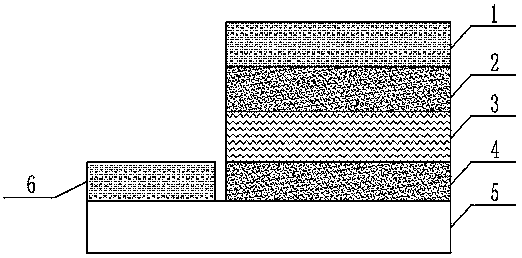

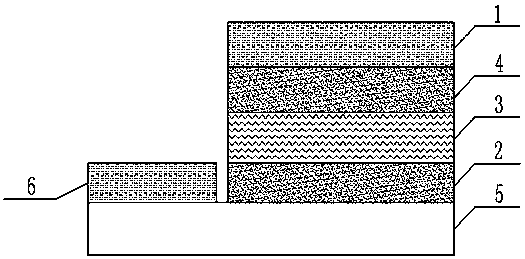

[0033] see figure 1 and Figure 3-4 , a method for preparing a flexible large-area perovskite solar cell based on a roll coating process, comprising the following steps:

[0034] Treatment of ITO flexible substrate (PET): treat the cleaned flexible conductive substrate with ultraviolet ozone;

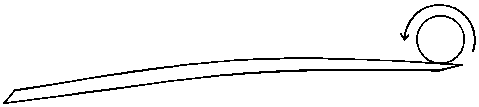

[0035] Fabrication of Electron Transport Layers on Flexible Conductive Substrates by Roll Coating Process: Addition of SnO 2 Aqueous solution of nanoparticles, immediately roll coating at a constant speed (such as image 3 shown), blow dry with nitrogen flow, and anneal at 100°C for 30 minutes to prepare electron transport layer 4;

[0036] Prepare CH 3 NH 3 I and PbI 2 mixed solution of PbI 2 The concentration is 0.5 mol / liter, the solvent adopts dimethylformamide, PbI 2 and CH 3 NH 3The molar ratio of I is 1:1 to prepare the perovskite precursor solution, drop the above mixed solution on the electron transport layer, immediately coat at a uniform speed and blow dry with nitr...

Embodiment 2

[0040] see figure 1 and Figure 3-4 , a method for preparing a flexible large-area perovskite solar cell based on a roll coating process, comprising the following steps:

[0041] Treatment of stainless steel substrate: treat the cleaned flexible conductive substrate with ultraviolet ozone;

[0042] Preparation of electron transport layer on flexible conductive substrate by roll coating process: adding nano-titanium dioxide (TiO 2 ) solution, immediately roll coating at a constant speed (such as image 3 shown), blow dry with nitrogen flow, and anneal at 200°C for 10 minutes to prepare electron transport layer 4;

[0043] Prepare CH 3 NH 3 I and PbCl 2 mixed solution of PbCl 2 The concentration is 1 mole / liter, then add the ionic liquid additive MY of precursor solution 10wt% (wherein A is ethylmethylamine salt cation, Y is formate ion; CH 3 NH 3 I and PbCl 2 The molar ratio is 3:1, the solvent is dimethylformamide and water, the volume ratio is 20:1), CH 3 NH 3 I. ...

Embodiment 3

[0047] see figure 1 and Figure 3-4 , a method for preparing a flexible large-area perovskite solar cell based on a roll coating process, comprising the following steps:

[0048] Treat polyethylene naphthalate (PEN) flexible substrate: treat the cleaned flexible conductive substrate with oxygen plasma;

[0049] Prepare the electron transport layer on the flexible conductive substrate by roll coating process: add nano-ZnO solution, roll coating at a constant speed immediately (such as image 3 shown), and dried with nitrogen flow, and annealed at 110° C. for 20 minutes to obtain an electron transport layer 4;

[0050] Prepare PbBr at a concentration of 1 mol / L 2 solution, add 0.1wt% ionic liquid additive MY (wherein, M is methylamidine salt cation, Y is propionate ion, and the solvent is N-methylpyrrolidone). First roll coat a layer of PbBr 2 After the mixed solution of MY and MY is naturally dried, roll-coat a solution of formamidine bromide with a concentration of 0.5 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com