In-situ autologous bionic repair material for fat liquefaction wound as well as preparation method and application of in-situ autologous bionic repair material

A repair material and autologous technology, applied in the direction of prosthesis, pharmaceutical formulation, medical science, etc., can solve the problems of poor healing, unsatisfactory healing cycle and prognosis scar, infection, etc., achieve good liquid absorption and air permeability, reduce prognosis Poor function, the effect of promoting physiological repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

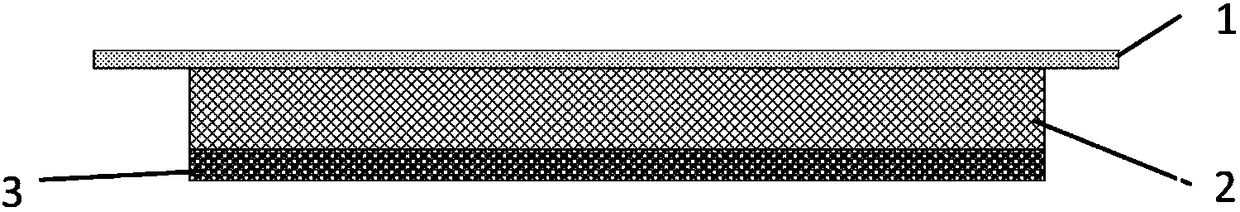

[0037] Example 1 Preparation of in-situ autologous biomimetic repair material for fat liquefaction wounds

[0038](1) Preparation of hydrophilic polyurethane film: referring to the classic medical polyurethane film preparation process, first prepare a prepolymer from hydrophilic polyethylene glycol and isocyanate in the presence of a crosslinking agent and a catalyst, and then dissolve the prepolymer In ethyl acetate, cast into a film with a thickness of about 0.1mm, cut into suitable sizes, and set aside;

[0039] (2) Apply pressure-sensitive adhesive evenly on one side of the prepared polyurethane film, and set aside;

[0040] (3) Chitosan fiber is woven into a multi-layer gauze structure by textile technology. The liquid absorption of the fiber layer is about 17 times its own weight, and the water vapor transmission rate is about 3937g.m -2 24 hours -1 ; The biological fiber layer is cut into suitable sizes for subsequent use;

[0041] (4) The biological fiber layer is p...

Embodiment 2

[0043] Example 2 In situ autologous bionic repair material for fat liquefaction wounds

[0044] (1) with embodiment 1;

[0045] (2) with embodiment 1;

[0046] (3) Using textile technology to blend chitosan fiber and calcium alginate fiber into a multi-layer gauze structure, chitosan fiber accounts for 70%, calcium alginate fiber accounts for 30%; the liquid absorption of the fiber layer is about 15 times Self-weight, water vapor transmission rate is about 3720g.m -2 24 hours -1 ; The biological fiber layer is cut into suitable sizes for subsequent use;

[0047] (4) with embodiment 1;

[0048] (5) with embodiment 1.

Embodiment 3

[0049] Example 3 In situ autologous bionic repair material for fat liquefaction wound

[0050] (1) with embodiment 1;

[0051] (2) with embodiment 1;

[0052] (3) Chitosan fiber, calcium alginate fiber and oxidized cellulose fiber are blended into a multi-layer gauze structure by textile technology, chitosan fiber accounts for 40%, calcium alginate fiber and oxidized cellulose fiber each account for 30%; The liquid absorption capacity of the fiber layer is about 16 times its own weight, and the water vapor transmission rate is about 3877g.m -2 24 hours -1 . The biological fiber layer is cut into applicable size and set aside;

[0053] (4) with embodiment 1;

[0054] (5) with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com