Organic fertilizer for promoting growth and increasing production and preparation method thereof

A technology of organic fertilizer and crop straw, which is applied in the field of growth-increasing organic fertilizer and its preparation, can solve the problems of not being able to be used as the main fertilization, uneven organic fertilizer, and single effect, and achieve the goals of accelerating resource utilization, improving drought resistance, and lasting fertilizer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

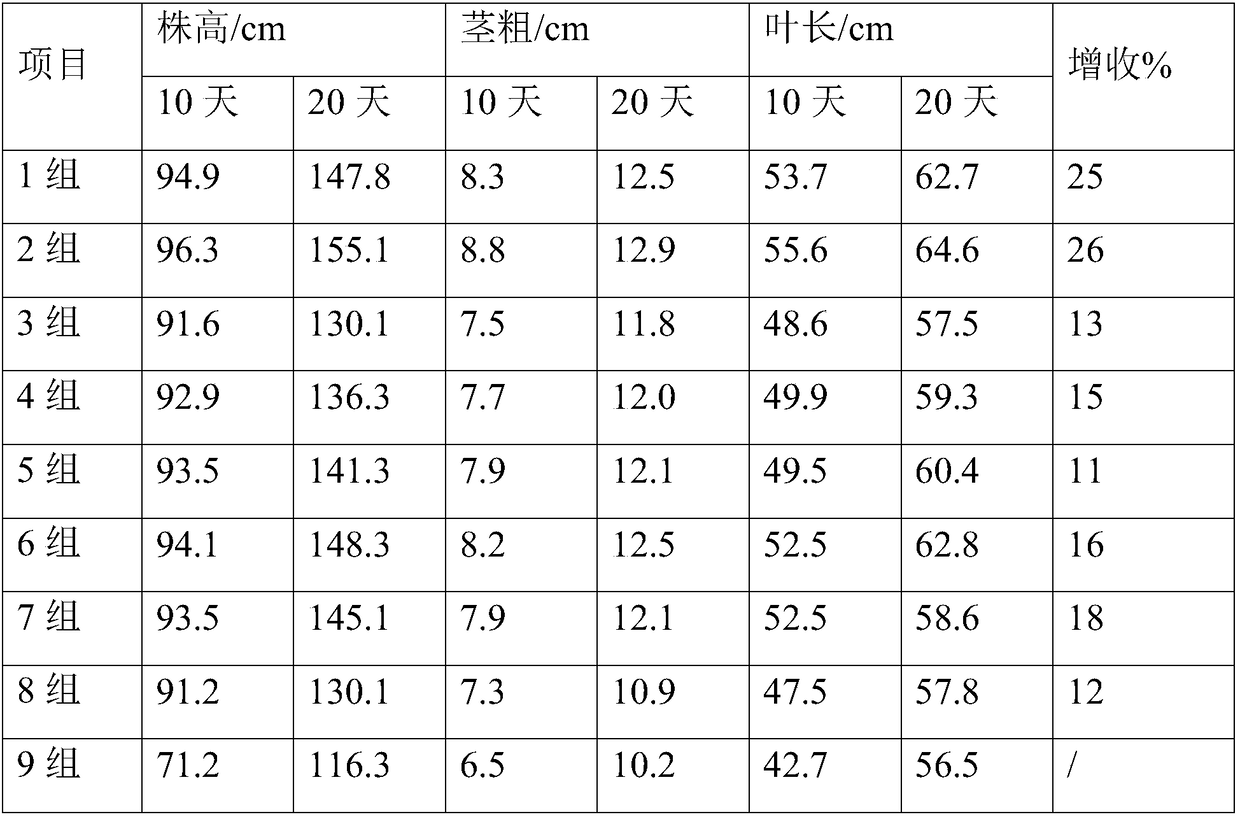

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the growth-promoting and income-increasing organic fertilizer, which may include the following steps:

[0033] (1) Grind the discarded mustard skin, Scenedesmus tenesmus, and motherwort, mix them evenly with crop straw powder, bean dregs, waste molasses, and traditional Chinese medicine dregs, add biologically active bacteria agents, and carry out fermentation. When the temperature rises to 55-65°C Turn over the pile once every 2 to 3 hours for a total of 2 to 3 times, then control the fermentation temperature to 38 to 43°C and seal the fermentation for 2 to 3 days to obtain the fermentation material;

[0034] (2) The fermented material obtained in step (1) is uniformly mixed with animal manure, yeast selenium, biological humic acid, monosodium glutamate residue, plant extract, plant growth promoter, compound trace elements, mineral powder and additives, and air-dried to obtain the product.

[0035] In the prese...

Embodiment 1

[0041] Take the following raw materials for use: 10 parts of discarded mustard skin, 10 parts of crop straw powder, 10 parts of bean dregs, 10 parts of animal manure, 5 parts of yeast selenium, 7 parts of monosodium glutamate residue, 10 parts of traditional Chinese medicine dregs, 5 parts of waste molasses, and sharp grid 13 parts of algae, 12 parts of plant extract, 3 parts of plant growth promoter, 5 parts of motherwort, 8 parts of biological humic acid, 13 parts of compound trace elements, 5 parts of mineral powder, 7 parts of bioactive bacteria agent, and 8 parts of additives.

[0042] Wherein, the composite trace element is a mixture of zinc sulfate, borax, manganese sulfate, ammonium molybdate and magnesium sulfate; the mineral powder includes zeolite powder, phosphate rock powder, potassium mineral powder, magnesium mineral powder, medical stone powder; The traditional Chinese medicine dregs are the waste after the preparation of Chinese patent medicines, and the tradit...

Embodiment 2

[0048] Take the following raw materials for use: 15 parts of discarded mustard skin, 15 parts of crop straw powder, 15 parts of bean dregs, 15 parts of animal manure, 8 parts of yeast selenium, 12 parts of monosodium glutamate residue, 15 parts of traditional Chinese medicine dregs, 10 parts of waste molasses, and sharp griddle 20 parts of algae, 15 parts of plant extract, 6 parts of plant growth promoter, 10 parts of motherwort, 13 parts of biological humic acid, 17 parts of compound trace elements, 10 parts of mineral powder, 10 parts of biologically active bacteria agent, and 15 parts of additives.

[0049] Wherein, the composite trace element is a mixture of zinc sulfate, borax, manganese sulfate, ammonium molybdate and magnesium sulfate; the mineral powder includes zeolite powder, phosphate rock powder, potassium mineral powder, magnesium mineral powder, medical stone powder; The traditional Chinese medicine dregs are the waste after the preparation of Chinese patent medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com