Device and method of preparing aluminum electrolysis anode anti-oxidation paint from aluminum clinker

An anti-oxidation coating, aluminum electrolytic anode technology, applied in lime coatings, coatings, etc., can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

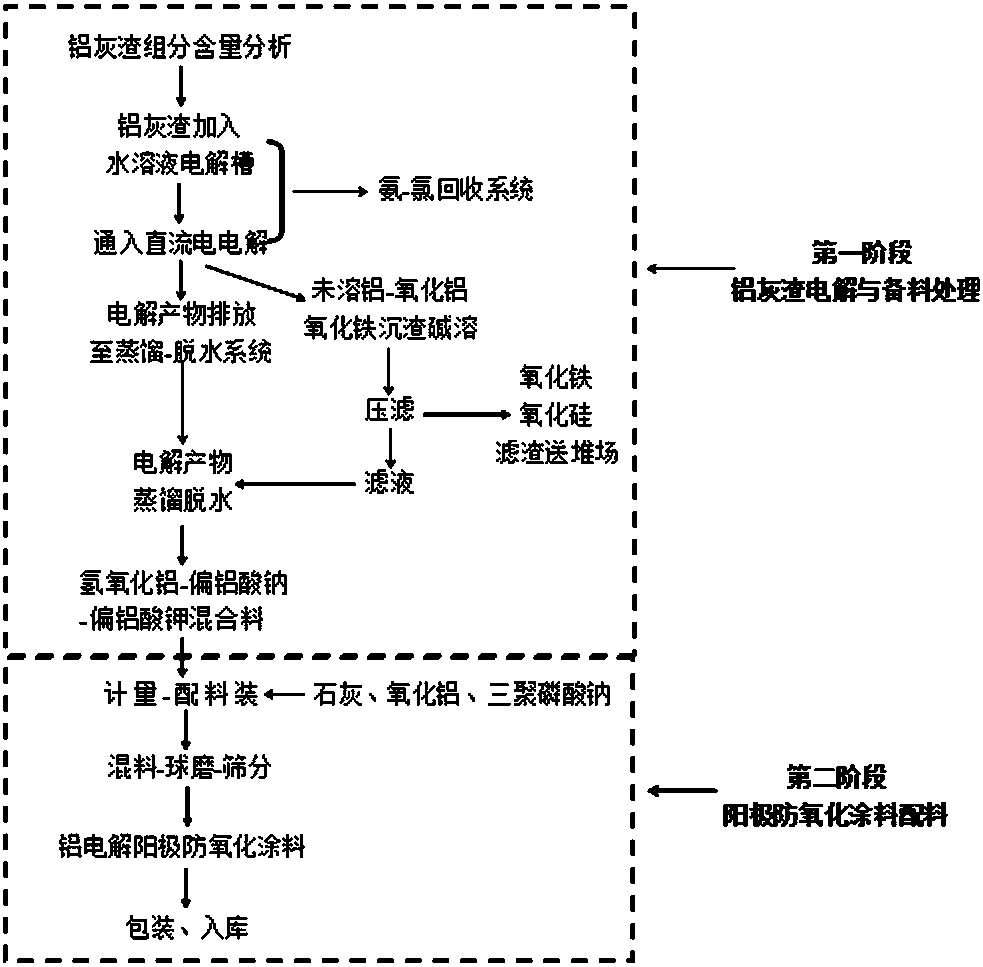

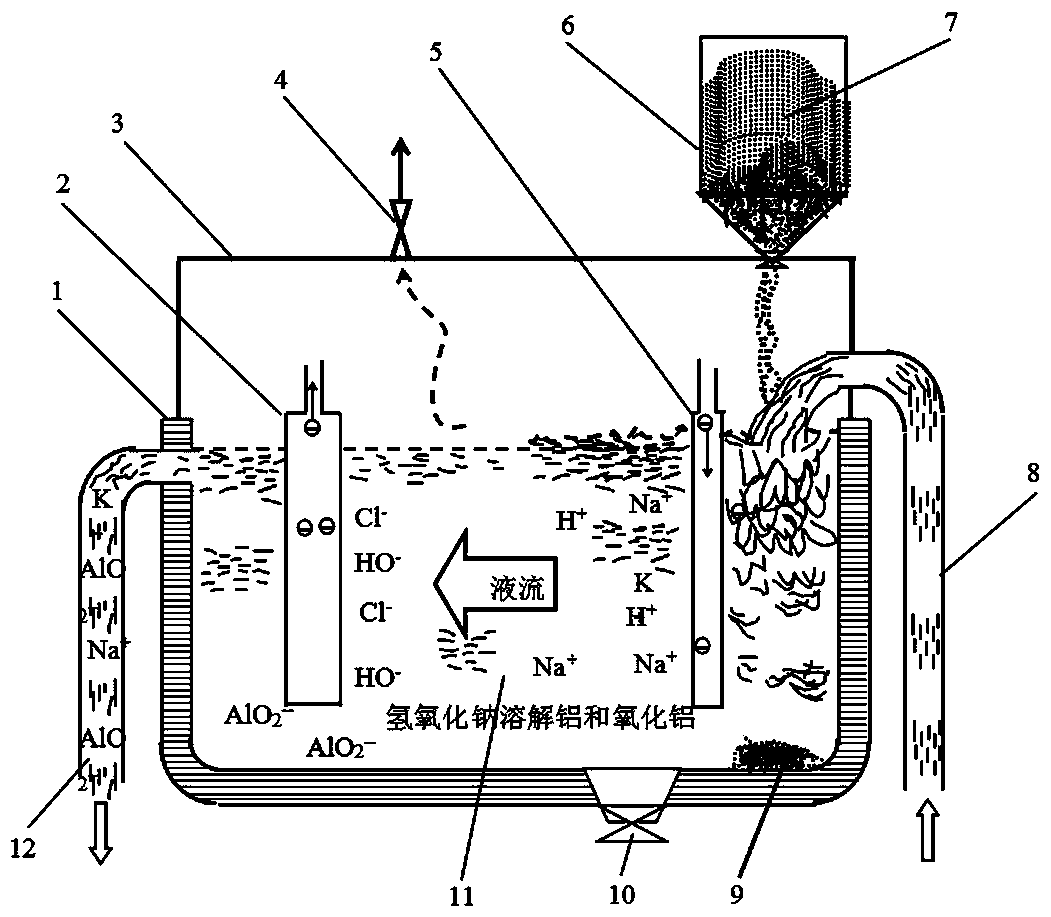

[0061] Analyze the content of aluminum, alumina, aluminum carbide, aluminum nitride, chloride salts, and fluorine salts in aluminum ash slag; add aluminum ash slag from the aluminum ash slag storage-feeding system into the electrolytic cell, and at the same time pass through the electrolytic cell water replenishment system Add sufficient distilled water to the electrolyzer. Hydrolyze and convert aluminum nitride, aluminum carbide, and aluminum fluoride into utilizable aluminum resources. Under the action of direct current, sodium chloride, potassium chloride, sodium fluoride, etc. in the aluminum ash slag undergo an electrolysis reaction, and the reaction products sodium hydroxide and potassium hydroxide are dissolved in the electrolyte, and then ammonia gas-chlorine gas- The fluorine recovery system recovers chlorine, fluorine and ammonia. Sodium hydroxide and potassium hydroxide in the electrolyte can dissolve aluminum and alumina in the precipitate to form sodium metaalumi...

Embodiment 2

[0066]Analyze the content of aluminum, alumina, aluminum carbide, aluminum nitride, chloride salts, and fluorine salts in aluminum ash slag; add aluminum ash slag from the aluminum ash slag storage-feeding system into the electrolytic cell, and at the same time pass through the electrolytic cell water replenishment system Add sufficient distilled water to the electrolyzer. Hydrolyze and convert aluminum nitride, aluminum carbide, and aluminum fluoride into utilizable aluminum resources. Under the action of direct current, sodium chloride, potassium chloride, sodium fluoride, etc. in the aluminum ash slag undergo an electrolysis reaction, and the reaction products sodium hydroxide and potassium hydroxide are dissolved in the electrolyte, and then ammonia gas-chlorine gas- The fluorine recovery system recovers chlorine, fluorine and ammonia. Sodium hydroxide and potassium hydroxide in the electrolyte can dissolve aluminum and alumina in the precipitate to form sodium metaalumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com