Nanometer tin based catalyst for electrochemical reduction carbon dioxide reaction and preparation method and application thereof

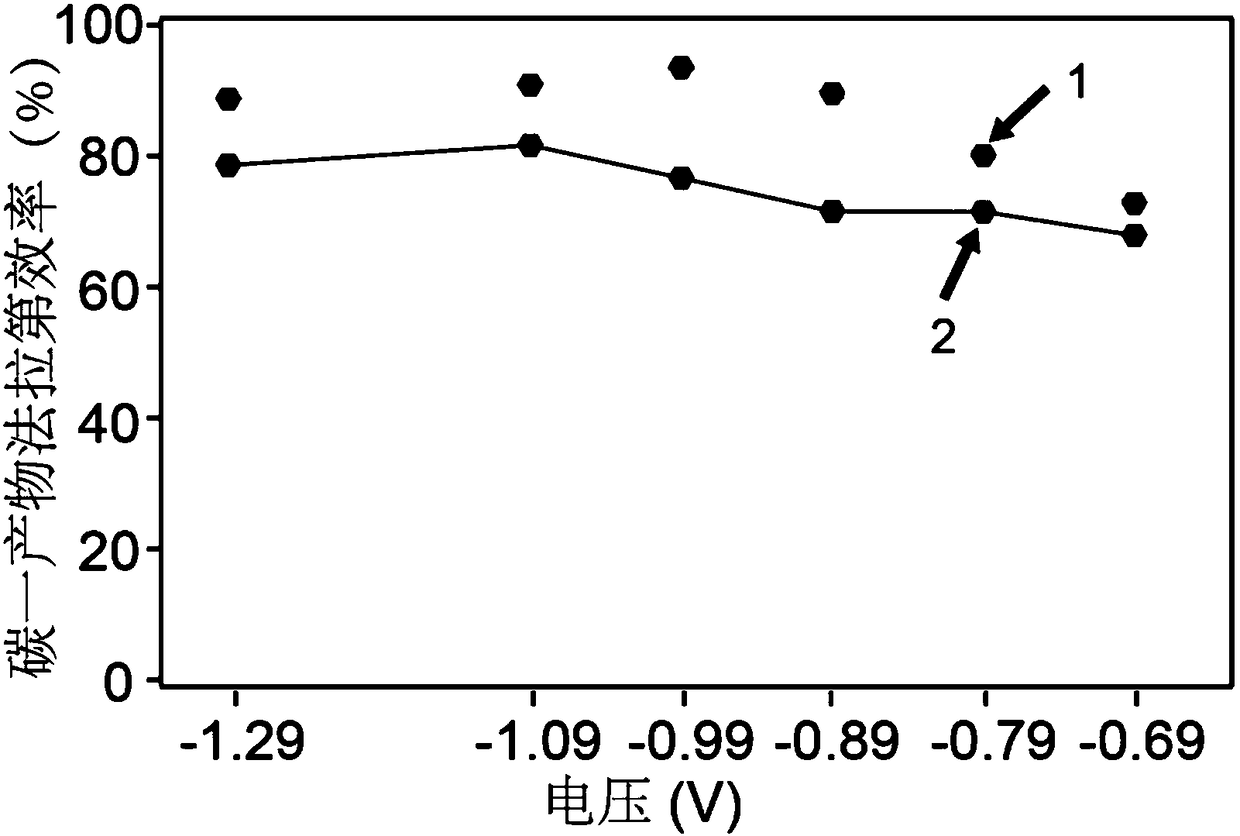

A technology of tin dioxide and carbon dioxide, applied in the direction of tin oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of tin-based catalysts with insufficient selectivity and low current density, so as to increase activity, Effect of increasing active sites and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

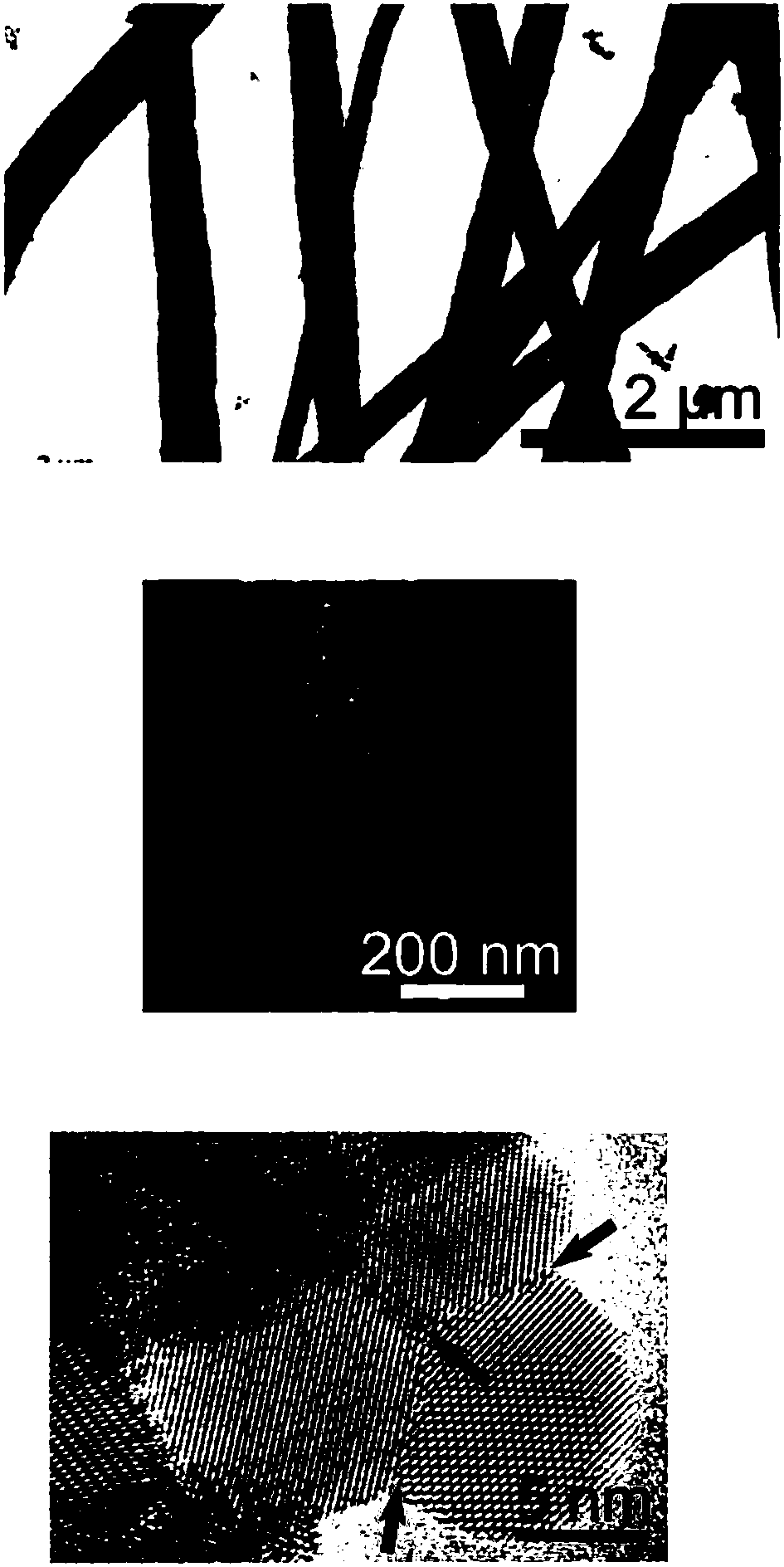

[0040] (1) Dissolve 1.0g polyvinylpyrrolidone (PVP, Mw=1,300,000) and 1.0g stannous chloride dihydrate in 5ml dimethylformamide (DMF) and 5ml ethanol mixed solvent, and stir at room temperature for 24h to obtain The spinning solution, which was transferred into a syringe, was placed on the syringe pump, and a piece of conductive carbon was placed 18 cm opposite to serve as the electrospinning receiver. Connect the high voltage power supply to the syringe needle and the ground wire to the conductive carbon. Apply high voltage of 15kV, the flow rate of the syringe pump is 0.3ml h -1 , after collecting for 4 hours, a composite fiber film of stannous chloride / polyvinylpyrrolidone / dimethylformamide / ethanol was obtained.

[0041] (2) Put the composite fiber film obtained in step (1) into a tube furnace and calcined for 2 hours in an air atmosphere, the calcining temperature was 500°C, and the heating rate was 5°C min -1 . Polyvinylpyrrolidone / dimethylformamide / ethanol will be dec...

Embodiment 2

[0048] (1) Mix 2.0g polyacrylonitrile (PAN, Mw=1,500,00) with 2.0g stannous acetate, 3ml N,N-dimethylformamide and 7ml dimethyl sulfoxide in a mixed solvent, stir at room temperature for 24h Finally, the spinning solution is obtained, which is transferred to a syringe, placed on a syringe pump, and a piece of conductive carbon is placed on the opposite side at 18 cm as an electrospinning receiving device. Connect the high voltage power supply to the syringe needle and the ground wire to the conductive carbon. Apply 20kV high voltage, the flow rate of the syringe pump is 0.4ml h -1 , after 4 hours of collection, the composite fiber film of stannous acetate / polyacrylonitrile / N,N-dimethylformamide / dimethyl sulfoxide was obtained.

[0049] (2) Put the composite fiber film obtained in step (1) into a tube furnace and calcinate for 1 h under air atmosphere, the calcining temperature is 400°C, and the heating rate is 5°C min -1 . N,N-dimethylformamide / dimethyl sulfoxide will be de...

Embodiment 3

[0053] (1) 0.5g polyvinyl alcohol (PAN, Mw=9,500,0) and 0.5g stannous sulfate are dissolved in 10ml water and 1ml ethanol mixed solvent, after stirring at room temperature for 24h, spinning solution is obtained, which is transferred to In the syringe, put it on the syringe pump, and place a piece of conductive carbon at the opposite side 18cm, as the electrospinning receiving device. Connect the high voltage power supply to the syringe needle and the ground wire to the conductive carbon. Apply high voltage of 15kV, the flow rate of the syringe pump is 0.5ml h -1 , after collecting for 4 hours, a stannous sulfate / polyvinyl alcohol / water / ethanol composite fiber film was obtained.

[0054] (2) Place the composite fiber film obtained in step (1) in a tube furnace and calcinate for 5 hours under air atmosphere, the calcining temperature is 650°C, and the heating rate is 5°C min -1 . The polyvinyl alcohol / water / ethanol will be decomposed and volatilized, the stannous sulfate will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com