Cyanide-free organic solvent electroplating gold solution

An organic solvent and gold electroplating technology, applied in the field of cyanide-free gold plating solutions, can solve the problems of poor uniformity and low gold quality, and achieve the effects of strong tolerance, high purity and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

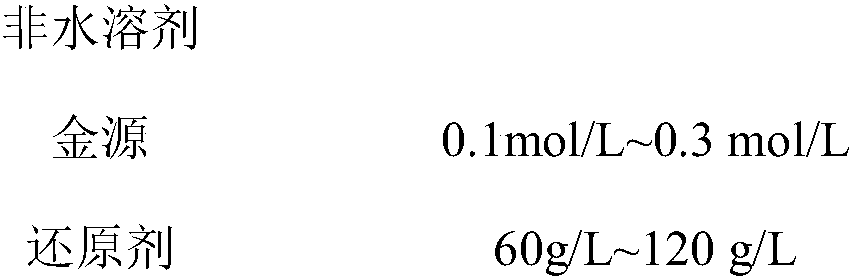

[0018] Embodiment one: a kind of electroplating solution of cyanide-free organic solvent, its composition is as follows:

[0019]

[0020] Prepare the gold plating solution according to the above composition, add it to the plating tank and control the distance between the cathode and the anode to be 5cm, and control the solution temperature and current density at 65°C and 15mA / cm respectively 2 , continuously stirring the solution evenly. The electroplating lasted for 1 hour, and the coating was compact, bright in color, and about 57 microns in thickness. At this time, the plating solution was colorless and clear, and no sediment appeared in the plating tank.

Embodiment 2

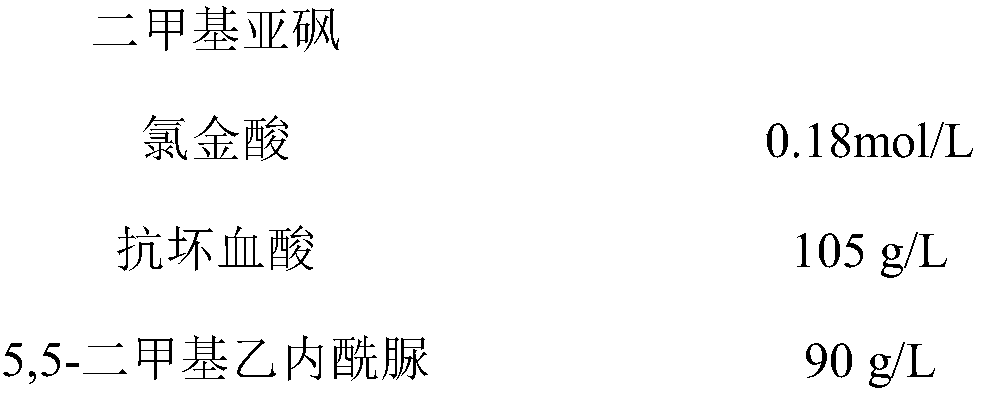

[0021] Embodiment two: a kind of electroplating solution of cyanide-free organic solvent, its composition is as follows:

[0022]

[0023] Prepare the gold plating solution according to the above composition, add it to the plating tank and control the distance between the cathode and the anode to about 5cm, and control the solution temperature and current density at 55°C and 10mA / cm respectively 2 , continuously stirring the solution evenly. The electroplating lasts for 1 hour, and the coating is compact, bright in color, and about 38 microns in thickness. At this time, the plating solution is colorless and clear, and no sediment occurs in the plating tank.

Embodiment 3

[0024] Embodiment three: a kind of electroplating solution of cyanide-free organic solvent, its composition is as follows:

[0025]

[0026] Prepare the gold plating solution according to the above composition, add it to the plating tank and control the distance between the cathode and the anode to about 5cm, and control the solution temperature and current density at 50°C and 5mA / cm respectively 2 , continuously stirring the solution evenly. The electroplating lasts for 1 hour, and the coating is compact, bright in color, and about 19 microns in thickness. At this time, the plating solution is colorless and clear, and no sediment occurs in the plating tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com