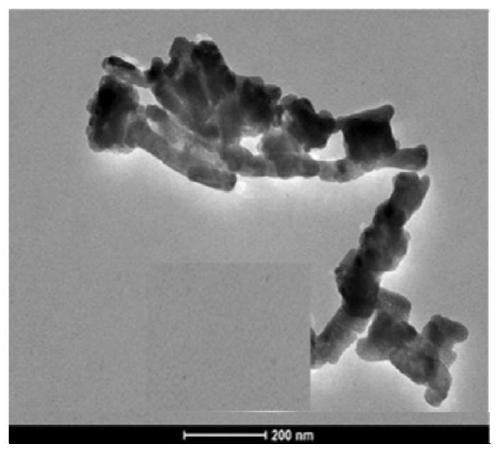

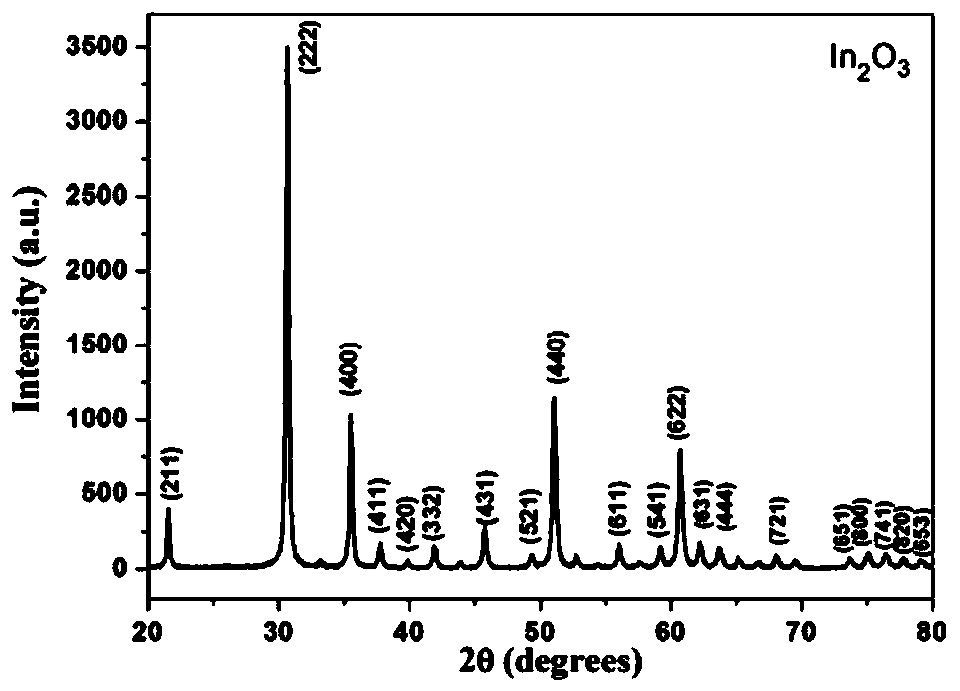

A kind of preparation method of nano-rod-shaped indium oxide gas-sensitive material

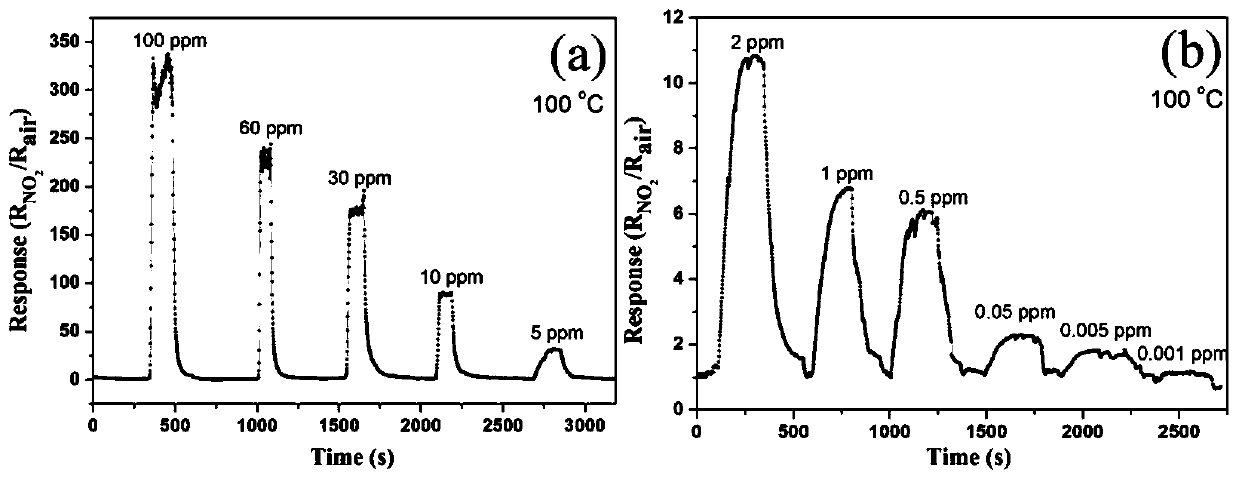

A nano-rod-shaped, indium gas-sensing technology, which is applied in the field of preparation of indium oxide gas-sensing materials, can solve the problems of simultaneous detection of nitrogen dioxide gas and hydrogen sulfide gas, etc., and achieve rapid response recovery, high stability, and high test sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1.10 g of indium trichloride tetrahydrate and add it into 50 ml of absolute ethanol to prepare a 0.075 mol / L ethanol solution of indium trichloride. Take 1.50g of sodium hydroxide and add it to 50ml of deionized water to prepare a 0.75mol / L NaOH aqueous solution.

[0024] Take 20mL of the above-mentioned indium trichloride ethanol solution and 20mL of the above-mentioned NaOH aqueous solution and mix, add 0.27g cetyltrimethylammonium bromide (CTAB) (molar ratio InCl 3 4H 2 O:CTAB=5:1), stirred for 1 hour.

[0025] Put the above prepared solution into a 50mL reaction kettle, then put it into a forced air drying oven, set the temperature at 180°C, and react for 12 hours. After the reaction, the obtained white precipitated product was washed with a mixed solution of deionized water and ethanol, and dried in a drying oven at 60° C. for 6 hours to obtain white indium hydroxide powder. The indium hydroxide powder was calcined in a muffle furnace at 500° C. for 2 hours...

Embodiment 2

[0028] Take 3.30 g of indium trichloride tetrahydrate and add it into 50 ml of absolute ethanol to prepare a 0.225 mol / L ethanol solution of indium trichloride. Take 3.0g of sodium hydroxide and add it into 50ml of deionized water to prepare a 1.50mol / L NaOH aqueous solution.

[0029] Take 20 mL of the above indium trichloride ethanol solution and 20 mL of the above NaOH aqueous solution and mix, add 0.60 g of cetyltrimethylammonium bromide (CTAB), and stir for 1 hour.

[0030] Put the above prepared solution into a 50mL reaction kettle, then put it into a forced air drying oven, set the temperature at 150°C, and react for 24 hours. After the reaction, the obtained white precipitated product was washed with a mixed solution of deionized water and ethanol, and dried in a drying oven at 100° C. for 2 hours to obtain white indium hydroxide powder. The indium hydroxide powder was calcined in a muffle furnace at 400° C. for 3 hours to obtain yellow indium oxide powder.

[0031] O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com