Alpha-Fe2O3/Au nanometer-circular-truncated-cone-array photoelectrode and preparing method and application thereof

A -fe2o3, photoelectrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of cumbersome steps, large dosage, poor array controllability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

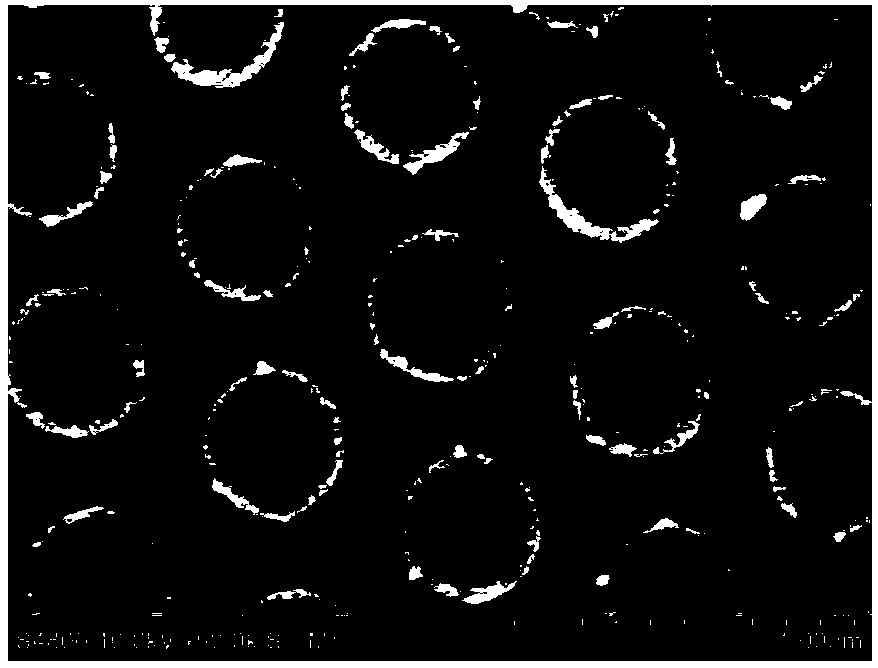

Image

Examples

Embodiment 1

[0083] (1) Dip the silicon wafer into a mixed solution of ammonia, hydrogen peroxide and water (the volume ratio of ammonia, hydrogen peroxide and water is 1:1:5), and then keep it warm at 75°C for 1 hour;

[0084] (2) Add water and 100 μL of sodium lauryl sulfate solution with a concentration of 2wt% into a petri dish with a diameter of 150 mm, place the silicon wafer treated in step (1) in the petri dish, and then use a syringe to inject Slowly add polystyrene ball solution with a diameter of 600nm and a concentration of 0.05g / mL to the petri dish, so that the polystyrene ball solution diffuses along the silicon chip into the solution of the petri dish, and the polystyrene ball will self-assemble on the surface of the petri dish Arranged to obtain a single-layer polystyrene spherical membrane;

[0085] (3) Place the cleaned quartz substrate under the single-layer polystyrene spherical membrane obtained in step (2), attach the single-layer polystyrene spherical membrane to th...

Embodiment 2

[0090] Compared with Example 1, except that the polystyrene sphere solution with a diameter of 300 nm is added dropwise in step (2), other steps and conditions are exactly the same as Example 1.

Embodiment 3

[0092] Compared with Example 1, except that the polystyrene sphere solution with a diameter of 440nm was added dropwise in step (2), other steps and conditions were exactly the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com