Halogen-free phosphazene expanding-type flame retardant and preparation method thereof

An intumescent flame retardant, halogen-free phosphazene technology, applied in the field of flame retardants, can solve the problems of uncontrollable reaction process, complicated product purification process, unfavorable industrial production, etc., and achieves high synthesis efficiency, improved thermal stability, Add less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 8.84ml triethylamine and 6.25g neopentyl glycol and 40ml tetrahydrofuran solvent in the 250ml three-neck flask equipped with reflux condenser, constant pressure titration funnel, thermometer and magnetic stirrer, simultaneously 6.95g hexachlorocyclotriphosphazene Dissolve in 20ml tetrahydrofuran and transfer to a constant pressure titration funnel, raise the temperature to 50°C under the protection of nitrogen, start to slowly add the hexachlorocyclotriphosphazene solution dropwise, after the drop, raise the temperature to 60°C for reflux for 7 hours, and stop the reaction. After cooling, it was filtered, and the filtrate was distilled under reduced pressure, recrystallized from ethyl acetate, and dried under vacuum at 65°C for 2 hours to obtain a white solid product. Yield 78.3%.

Embodiment 2

[0030] Add 8.84ml triethylamine and 6.25g neopentyl glycol and 40ml tetrahydrofuran solvent in the 250ml three-neck flask equipped with reflux condenser, constant pressure titration funnel, thermometer and magnetic stirrer, simultaneously 6.95g hexachlorocyclotriphosphazene Dissolve in 20ml tetrahydrofuran and transfer to a constant pressure titration funnel, raise the temperature to 50°C under the protection of nitrogen, start to slowly add the hexachlorocyclotriphosphazene solution dropwise, after the drop, raise the temperature to 70°C and reflux for 5 hours to stop the reaction. After cooling, it was filtered, and the filtrate was distilled under reduced pressure, recrystallized from ethyl acetate, and dried under vacuum at 65°C for 2 hours to obtain a white solid product. Yield 81.4%.

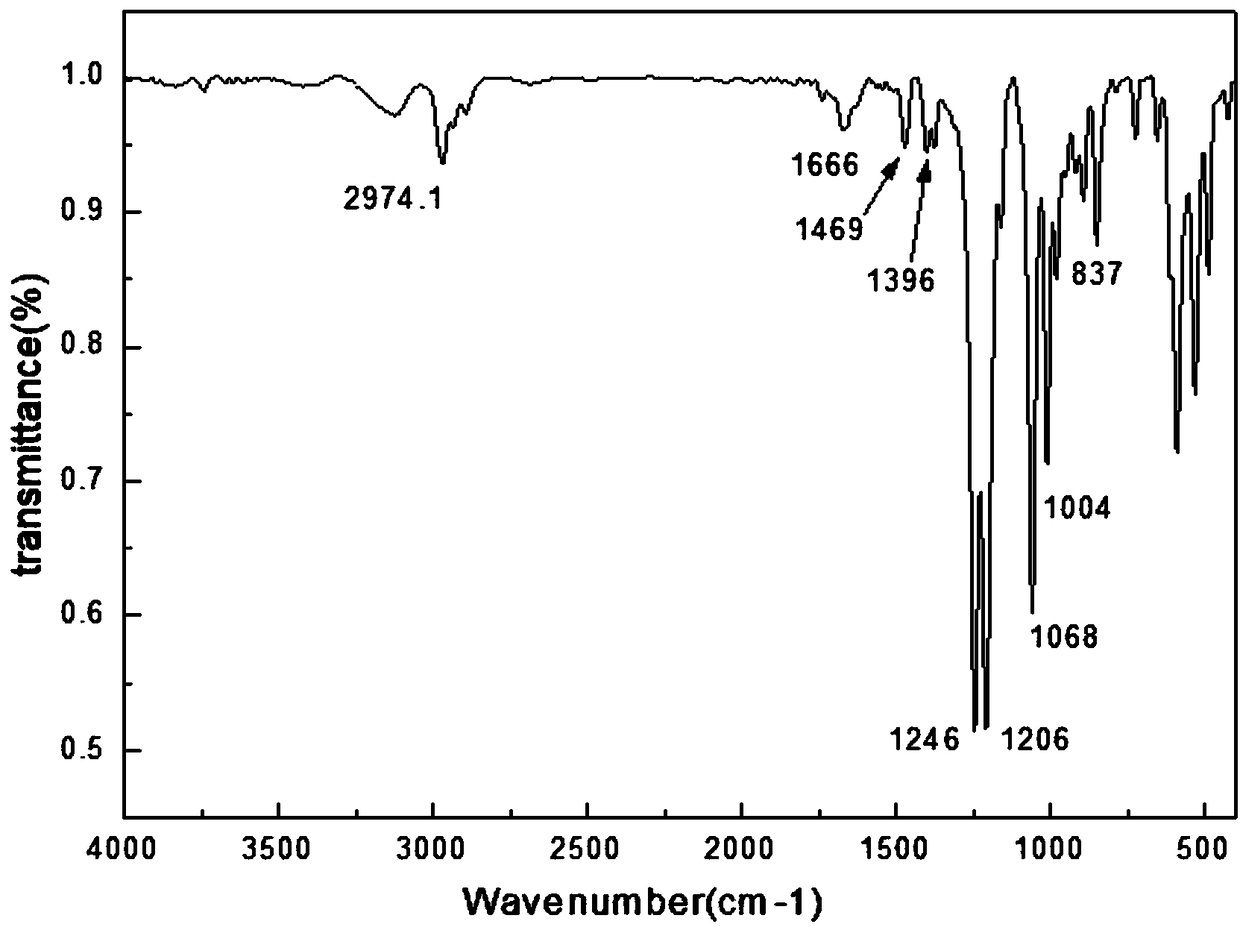

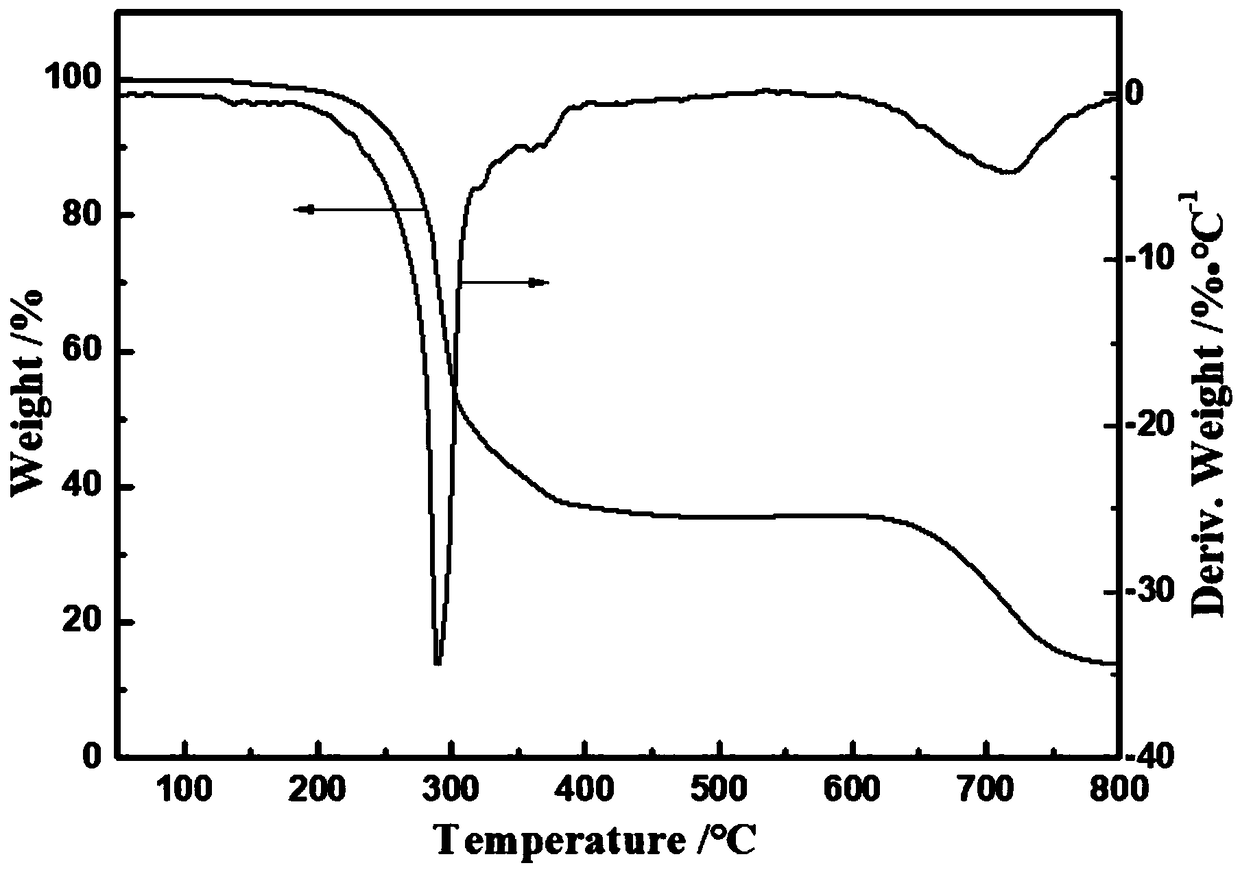

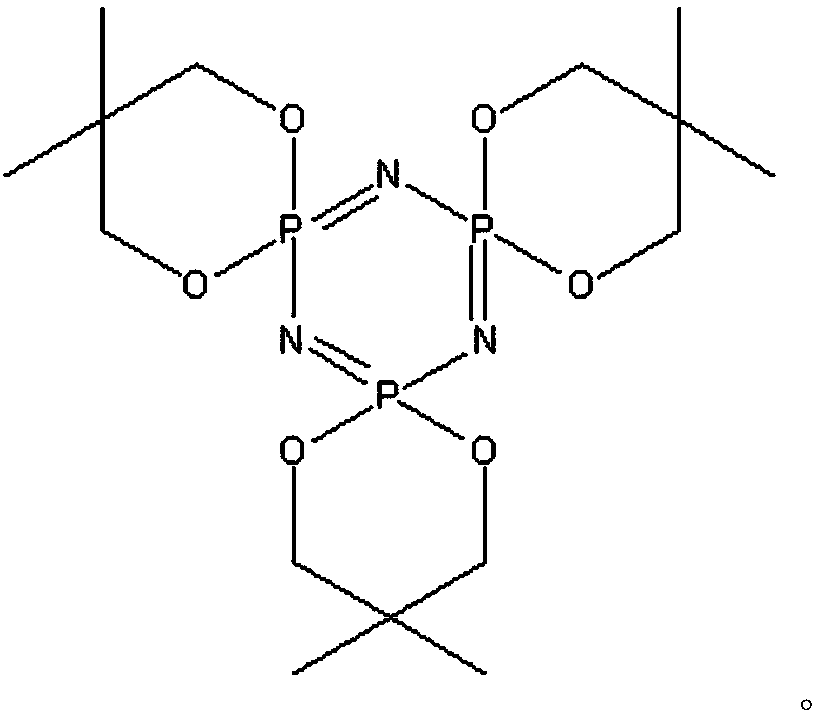

[0031] The infrared characterization figure of the product obtained in this embodiment is as follows figure 1 As shown, wherein: 2974cm-1 is the C-H vibration absorption peak of the methy...

Embodiment 3

[0034] Add 8.84ml triethylamine and 6.25g neopentyl glycol and 40ml tetrahydrofuran solvent in the 250ml three-neck flask equipped with reflux condenser, constant pressure titration funnel, thermometer and magnetic stirrer, simultaneously 6.95g hexachlorocyclotriphosphazene Dissolve in 20ml tetrahydrofuran and transfer to a constant pressure titration funnel, raise the temperature to 50°C under the protection of nitrogen, start to slowly add the hexachlorocyclotriphosphazene solution dropwise, after the drop, raise the temperature to 70°C and reflux for 7 hours to stop the reaction. After cooling, it was filtered, and the filtrate was distilled under reduced pressure, recrystallized from ethyl acetate, and dried under vacuum at 65°C for 2 hours to obtain a white solid product. Yield 86.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com