Injectable polymer hydrogel based on acylhydrazone bond, preparation method thereof and polymer hydrogel injection

A polymer hydrogel, acylhydrazone bond technology, applied in pharmaceutical formulations, pharmaceutical sciences, prostheses, etc., can solve the problem of mechanical strength, structure and comprehensive performance cannot be unified and jointly improved, complex composition and structure, poor fluidity, etc. problem to achieve excellent injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing an injectable polymer hydrogel based on an acylhydrazone bond, which includes:

[0043] Step 110, component 1 obtained by introducing a hydrazide group into a polysaccharide polymer through a chemical modification method;

[0044] Step 112, introducing aldehyde groups into polyvinyl alcohol, hydroxyl-terminated polyethylene glycol, and / or polyethylene oxide-polyoxypropylene-polyoxyethylene by chemical modification to obtain component 2;

[0045] Step 114, at room temperature, mix component 1 and component 2 with water solvent according to a preset ratio to obtain mixture 1 and mixture 2;

[0046] Step 116, mix the mixture 1 and the mixture 2, stir and gel evenly.

[0047] Normal temperature is mentioned in step 114, that is, the natural temperature without adding any temperature adjustment disturbance factors. Temperature values in the range of 22-37°C are preferred.

[0048] The present invention also prov...

Embodiment 1

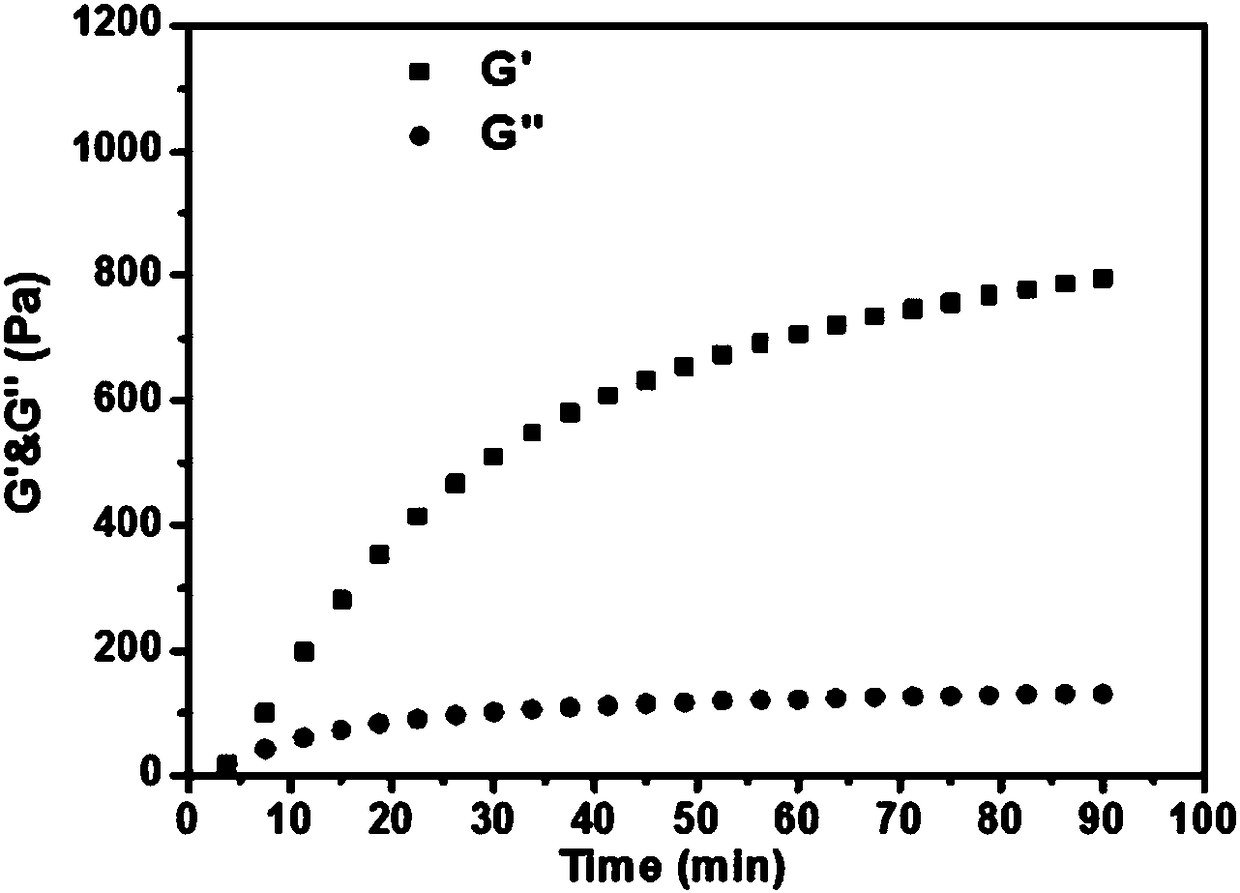

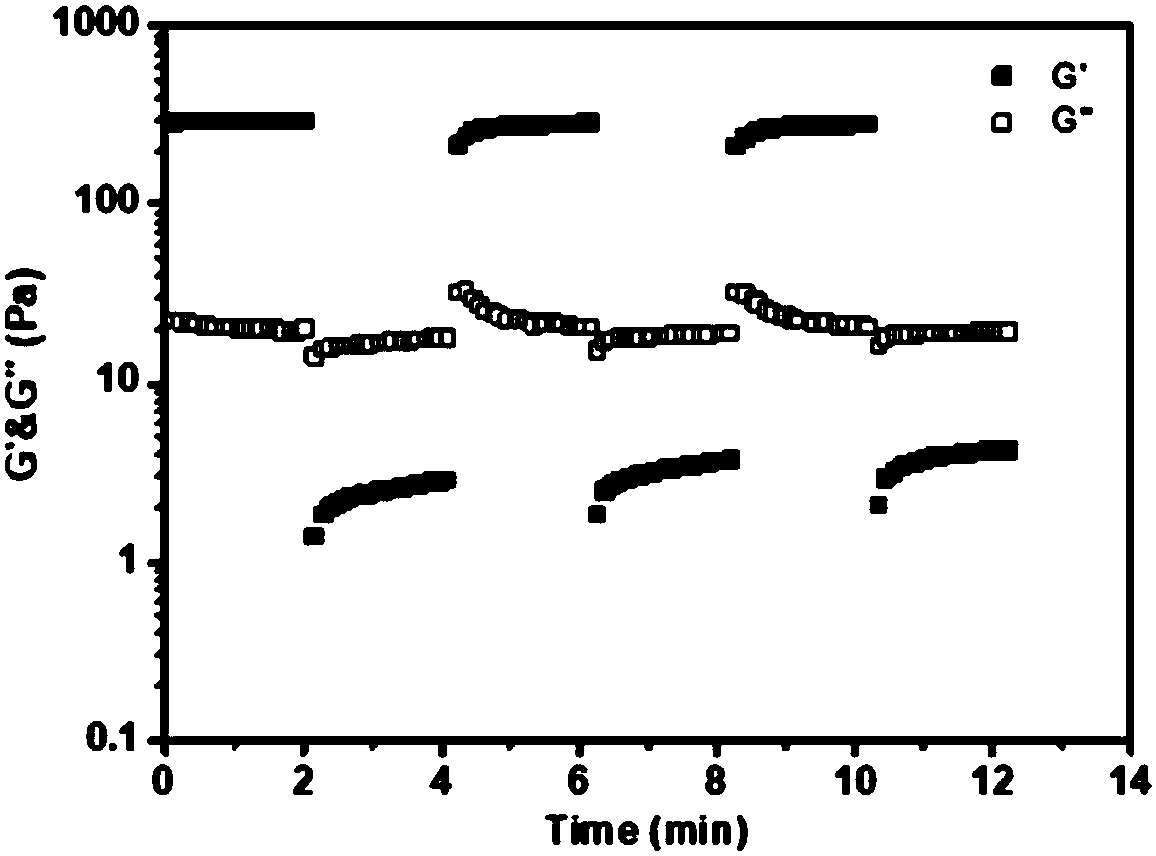

[0051] Dissolve 1.0 g of hydrazide-modified sodium alginate (Alg-HZ) and aldehyde-modified poloxamer (PVA-AH) 1.0 g in 10 mL of aqueous solution, shake and mix the two to obtain water A gel precursor solution that gradually cross-links into a hydrogel over time.

Embodiment 2

[0053] Dissolve 1.0 g of hydrazide-modified sodium hyaluronate (HA-HZ) and aldehyde-modified poloxamer (PVA-AH) 1.0 g in 10 mL of aqueous solution, shake and mix the two evenly to obtain A hydrogel precursor solution that gradually cross-links into a hydrogel over time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com