Multiple-effect citrate-soluble silicon fertilizer, and preparation method and application of silicon fertilizer

A technology of citrate-soluble silicon and silicon fertilizer, which is applied in the application field of farmland soil, can solve the problems of insufficient utilization of silicon resources, impact on the surrounding environment, and high cost of silicon fertilizer, so as to reduce agricultural production costs, improve soil environment, and produce short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

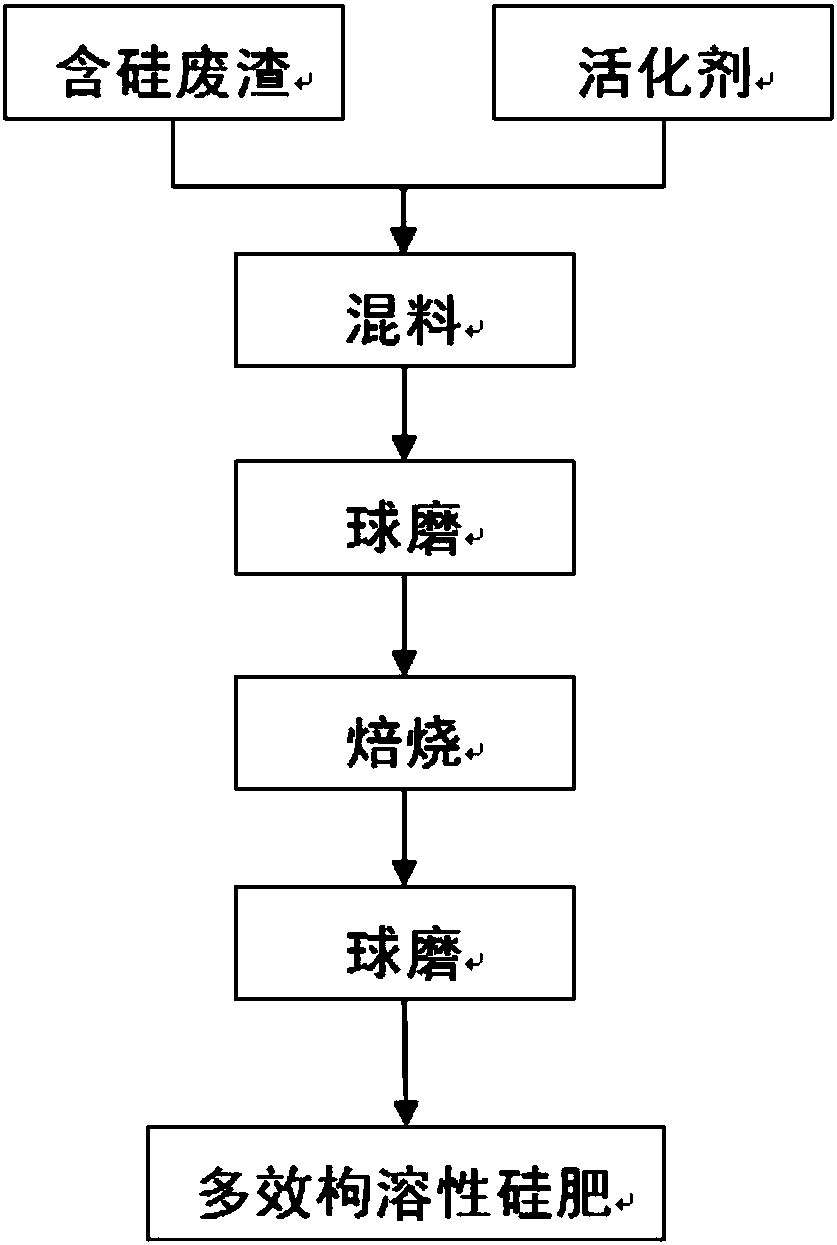

[0023] Such as figure 1 As shown, the preparation method of the present invention includes: firstly mixing and pulverizing silicon-containing waste slag and activator thoroughly, then using a rotary furnace for high-temperature roasting treatment, and finally pulverizing to obtain a multi-effect citric-soluble silicon fertilizer.

[0024] Applying the multi-effect citrate-soluble silicon fertilizer as a base fertilizer to farmland soil has a good effect on improving soil fertility and promoting crop production.

[0025] The invention not only solves the problem of resource utilization of silicon-containing waste residue, but also obtains a multi-effect citric-soluble silicon fertilizer with long fertilizer efficiency, not easy to lose, and simple preparation process, short production cycle, easy to achieve large-scale production, and can achieve relatively High economic and social benefits.

Embodiment 1

[0027] Take some industrial leaching waste residue containing silicon, its total silicon dioxide content is 69.41%, and the active silicon content is only 0.02%. After fully mixing the silicon-containing waste residue, potassium carbonate and calcium carbonate at 56%, 22% and 22% by weight, the mixture is ball milled to a particle size of less than 100 mesh.

[0028] Place the material in a rotary kiln at 800°C for full roasting. The roasting time is 60 minutes. After roasting, it is ground to 250 meshes, which is a multi-effect citric soluble silicon fertilizer, and its effective silicon content reaches 24.8%.

[0029] Using this citrate-soluble silicon fertilizer as a base fertilizer, a comparative test of increasing the yield of Chinese cabbage was carried out. The test group applied silicon fertilizer to the farmland at an application rate of 100 kg per mu, and the control group did not use silicon fertilizer under the same conditions. After one month of growth, the yield of Ch...

Embodiment 2

[0031] Take some industrial baking slag containing silicon, its total silicon dioxide content is 58.85%, and the active silicon content is only 0.08%. After fully mixing the silicon-containing roasting slag, potassium carbonate and calcium carbonate at 50%, 25%, and 25% by weight, the mixture is ball milled to a particle size of less than 100 mesh.

[0032] The material is fully roasted at 800°C for 60 minutes. After the roasting is completed, it is ground to 250 meshes, which is a multi-effect citrate-soluble silicon fertilizer, and its effective silicon content reaches 25.7%.

[0033] The citrate-soluble silicon fertilizer was used as the base fertilizer to carry out a comparative test of increasing the yield of radish. The test group applied silicon fertilizer to the farmland at an application rate of 100 kg per mu. The control group did not use silicon fertilizer under the same conditions. After three months of growth, the yield of radish in the experimental field was 9.69 kg p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com