Method for regenerating reducing sugar from hydrazine chromophoric reagent derivative of reducing sugar

A chromogenic reagent and derivative technology, applied in the field of biochemistry, can solve the problems of high yield of by-products, harsh reaction conditions, low yield of reducing sugar chains, etc., and achieves high recovery rate, mild reaction and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

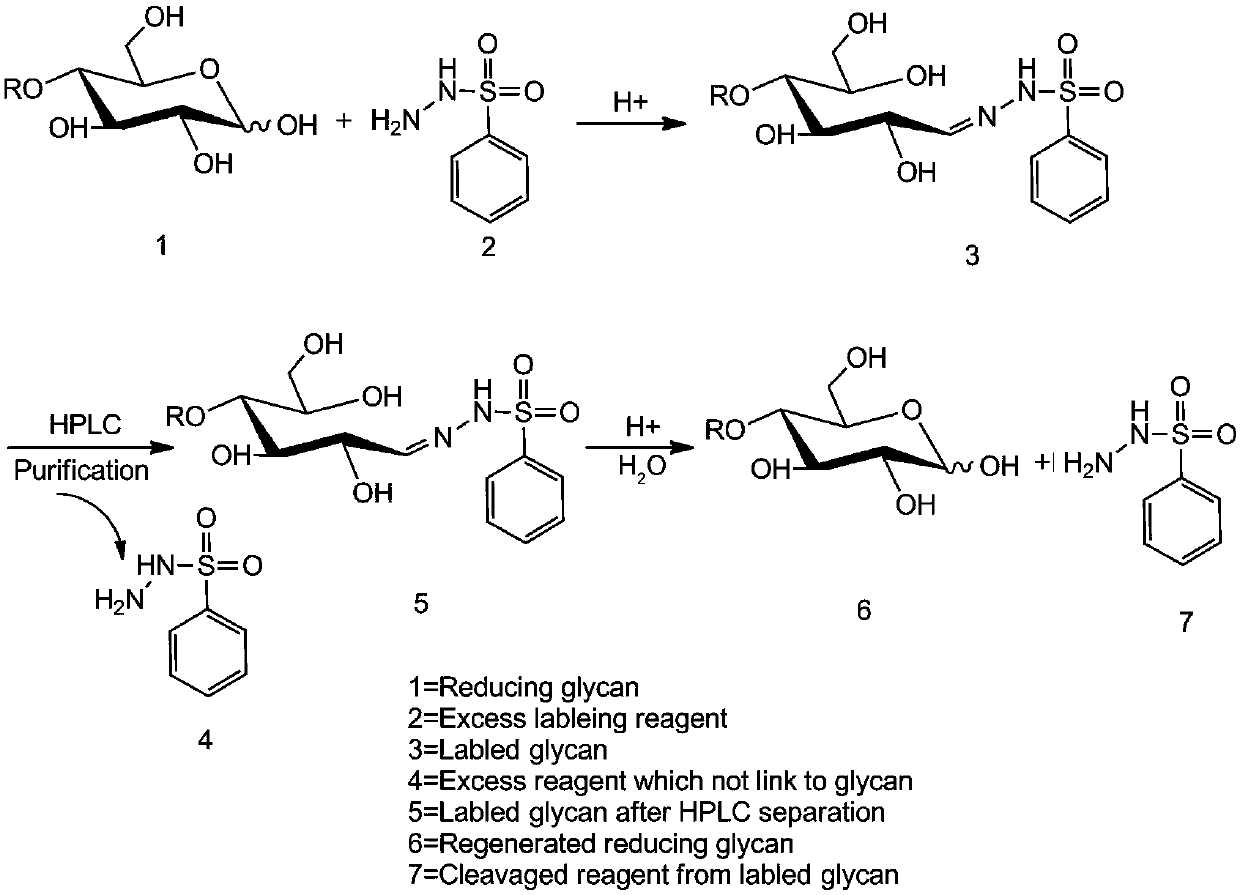

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

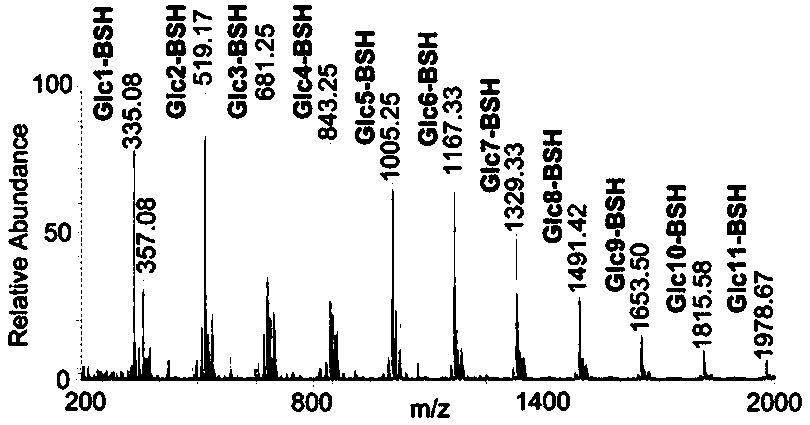

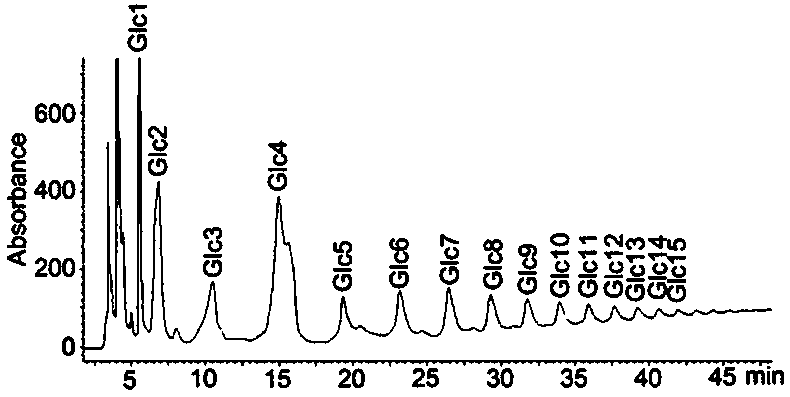

[0063] Example 1: Regeneration of free reduced maltooligosaccharide monomers from BSH derivatives of maltodextrin

[0064] Specific steps are as follows:

[0065] (1) Take 5 mg of standard maltodextrin, take BSH (10 mg) according to the molar ratio of not less than 1:10, and dissolve maltodextrin and BSH in 1 mL of weak acid aqueous solution of organic solvent (500 μL ethanol + 50 μL acetic acid + 450 μL Water=1mL, containing 50% ethanol and 5% acetic acid), shake well, react at 60°C for 45min, then concentrate and dry.

[0066] (2) The obtained sample was dissolved in water, then extracted with an organic solvent (dichloromethane), centrifuged, and the supernatant was taken, and repeated 3-5 times, and finally the obtained supernatant was concentrated and dried.

[0067] (3) Dissolve the obtained sample with acetonitrile, and then perform HILIC-HPLC separation. The liquid phase conditions are: when performing HILIC-HPLC separation, use a 4.6mm×250mm TSK-GEL Amide-80 column, ...

Embodiment 2

[0070] Example 2: Regeneration of free reduced maltooligosaccharide monomers from TSH derivatives of maltodextrin

[0071] Specific steps are as follows:

[0072] (1) Take 5 mg of standard maltodextrin, take TSH (10 mg) according to the molar ratio of not less than 1:10, dissolve maltodextrin and TSH in 1 mL of weak acid aqueous solution of organic solvent (500 μL ethanol + 50 μL acetic acid + 450 μL Water=1mL, containing 50% ethanol and 5% acetic acid), shake well, react at 60°C for 45min, then concentrate and dry.

[0073] (2) The obtained sample was dissolved in water, then extracted with an organic solvent (dichloromethane), centrifuged, and the supernatant was taken, and repeated 3-5 times, and finally the obtained supernatant was concentrated and dried.

[0074] (3) Dissolve the obtained sample with acetonitrile, and then perform HILIC-HPLC separation. The liquid phase conditions are: when performing HILIC-HPLC separation, use a 4.6mm×250mm TSK-GEL Amide-80 column, the ...

Embodiment 3

[0077] Example 3: Regeneration of free reduced maltooligosaccharide monomers from BZH derivatives of maltodextrin

[0078] Specific steps are as follows:

[0079] (1) Take 5 mg of standard maltodextrin, take BZH (10 mg) according to the molar ratio of not less than 1:10, dissolve maltodextrin and BZH in 1 mL of weak acid aqueous solution of organic solvent (500 μL ethanol + 50 μL acetic acid + 450 μL Water=1mL, containing 50% ethanol and 5% acetic acid), shake well, react at 60°C for 45min, then concentrate and dry.

[0080] (2) Dissolve the obtained sample in water, then pass through C18 and PGC solid-phase extraction column to purify the sample, first pass through the C18 column, the specific operation is: 3mL acetonitrile activation, 12mL water balance, sample loading, then 0%, 5%, 10%, 15% acetonitrile washes 3mL every 5% gradient to remove impurities, 3mL 20% acetonitrile elutes the sugar chain, and then passes through the PGC column. The specific operation is: 3mL aceto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com